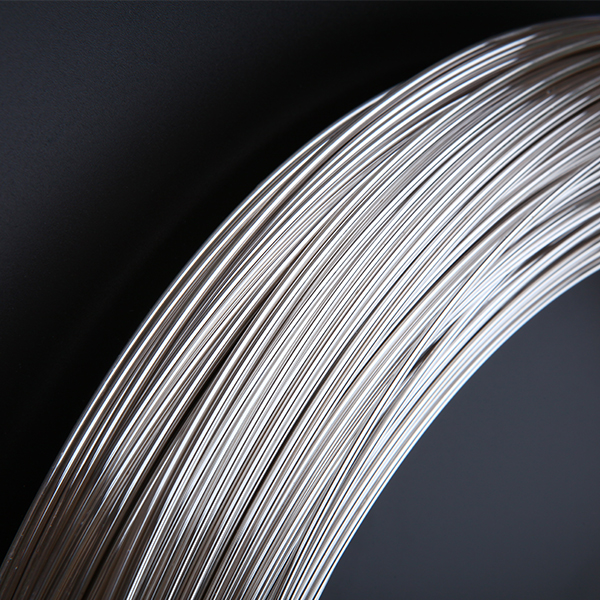

Izintambo zeSilver Alloy

| Isicelo: |

| Oxhumana nabo, ama-circuit breaker, ama-thermostat, amaswishi ahlakaniphile, njll |

| Okubalulekile: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Isakhiwo esincane

2. Incazelo Ejwayelekile

Isiliva nesiliva elicolekileyo lokusanhlamvu (i-FAg) linogesi ophakeme kakhulu kanye ne-thermal conductivity, ukumelana nokuxhumana okuphansi nokuzinzile, nokusebenza kahle.Ukuze ukumelana nesiliva ekugugulekeni kwe-arc kanye ne-welding yokuxhumana kulinganiselwe, amandla emishini aphansi, Ngenxa yobuncane be-nickel esiliva okusanhlamvu okuhle, ukumelana nokuguguleka kwe-arc namandla emishini kuphakeme kunesiliva.

3. Ububanzi Bokusebenza

Isetshenziswa kakhulu kumadivayisi amanje aphansi, afana nama-relay, izibali sikhathi, amaswishi ayisizayo ezinto zikagesi zasendlini , amaswishi okulawula, njll.

4. Izinto ezibonakalayo

| Ag | I-FAg | |||

| Amathiphu | Izintambo | Amathiphu | Izintambo | |

| Okuqukethwe kwe-Ag (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Ukuminyana (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Ukungazweli (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Ubulukhuni HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Amandla Okuqina (MPa) |

| 230-380 |

| 250-380 |

| Ubude (%) |

| 2-30 |

| 2-30 |

| Inqubo yokukhiqiza | I-Extruding-Rolling | Ikhipha -Umdwebo | I-Extruding-Rolling | Ikhipha -Umdwebo |

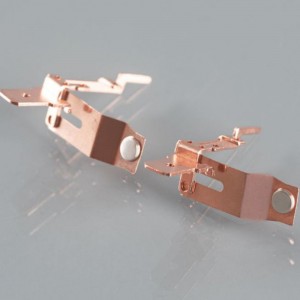

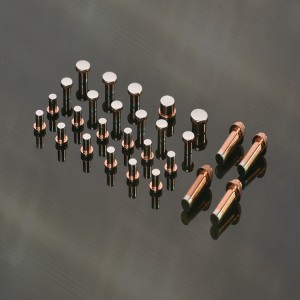

5. Izinhlobo Zomkhiqizo

AgNi

1. Isakhiwo esincane

2. Incazelo Ejwayelekile

Izinto ze-AgNi zinokumelana okuphezulu nokuguguleka kwe-arc kanye ne-welding yokuxhumana kune-Ag noma i-FAg.Zombili izakhiwo ziyathuthukiswa ngokuqukethwe kwe-Ni okwandayo.Zonke izinto ze-AgNi zibonisa ukusebenza kahle futhi kulula ukuzishisela ukuxhumana nezisekelo.Ukuthambekela okuphansi kokudluliswa kwempahla ezinhlelweni ze-DC.Izinto ze-AgNi ziyizinto ezivikela imvelo.

3. Ububanzi Bokusebenza

Izinto zokuxhumana ze-AgNi zithola uhlelo olubanzi kumadivayisi okushintsha amandla kagesi aphansi.Asetshenziswa kuma-relay, othintana nabo abancane, ama-switch light, izilawuli zezinga lokushisa kanye namaswishi okuvikela (asetshenziswa kumapheya okuxhumana a-asymmetric, ngokwesibonelo, ngokumelene ne-AgC, AgZnO noma izinto ze-AgSnO2).

4. Izinto ezibonakalayo

| Izintambo | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ni Okuqukethwe (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Ukuminyana (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| I-Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Ubulukhuni HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Amandla Okuqina (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Ubude(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Inqubo yokukhiqiza | I-Sintering-Extruding | |||||

5. Izinhlobo Zomkhiqizo

I-AgCdO

1. Isakhiwo esincane

2. Incazelo Ejwayelekile

Oxhumana nabo be-AgCdO bayingxenye yeqembu lalabo abasetshenziswa kakhulu emkhakheni wezinto ezisetshenziswayo zikagesi ezisezingeni eliphansi.Bahlanganisa ukumelana okwanelisayo ngokumelene ne-welding yokuxhumana nokumelana okuhle nokuguguleka kwe-arc kanye nokumelana nokuxhumana okuphansi kakhulu phakathi nokuphila kwayo okuphelele kwesevisi.Akhiqizwa ngamasu amabili ahlukene, i-pre-oxidation-sintering-extruding kanye ne-oxidation yangaphakathi.Kuzo zombili izimo okuqukethwe kwe-Cd0 kungase kusuke ku-10 kuye ku-20wt.. Nokho, i-Cd ne-Cd0 kuthathwa njengokuyingozi empilweni nasemvelweni.Ngalesi sizathu ukusetshenziswa kwezinto ze-AgCdO kuzovinjelwa emazweni amaningi.

3. Ububanzi Bokusebenza

Isetshenziswa kakhulu cishe kuzo zonke izinhlobo zamadivayisi okushintsha amandla kagesi aphansi.Ngokuvamile asetshenziswa kuma-microswitch, ama-relay, amaswishi okukhanya, abathintwayo, amaswishi ezinto zikagesi zasendlini, ezinye izinhlobo zamaswishi okuzivikela, kanye nasezinhlotsheni ezithile zama-breaker circuit.

4. Izinto ezibonakalayo

| Izintambo | I-AgCdO | I-AgCdO | I-AgCdO | I-AgCdO | I-AgCdO | I-AqCd0 | I-AgCdO |

| Okuqukethwe kwe-CdO(wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Ukuminyana (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| I-Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Ubulukhuni HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Amandla Okuqina (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Ubude(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Inqubo yokukhiqiza | I-Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||||

5. Izinhlobo Zomkhiqizo

AgZnO

1. Isakhiwo esincane

2. Incazelo Ejwayelekile

Ukumelana okuphezulu ngokumelene ne-welding yokuxhumana kubonisa izinto ze-AgZnO.Ziphinde zibonise ukumelana okuhle nokuguguleka kwe-arc.Ukumelana nokuxhumana kwe-AgZnO kuvame ukuba phezulu kunalokho kwe-AgCd0.I-AgZnO ingakhiqizwa ngendlela ye-pre-oxidation-sintering—extruding, mixing-compacting-sintering techniques kanye ne-oxidation yangaphakathi.Izinto ze-AgZnO ziyizinto ezivikela imvelo.

3. Ububanzi Bokusebenza

Isetshenziswa kakhulu kuma-circuit breaker, ikakhulukazi kuma-circuit breaker.Eminye imikhakha yesicelo ama-switch okuvikela izimoto, ama-breaker circuit asele kanye nama-AC relay.

4. Izinto ezibonakalayo

| Izintambo | AgZnO | AgZnO |

| Okuqukethwe kwe-ZnO(wt.%) | 8±1 | 10±1 |

| Ukuminyana (g/cm3) | .9.65 | 9.60 |

| I-Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Ubulukhuni HV | E30 | 85 |

| Amandla Okuqina (MPa) | 285-350 | 285-350 |

| Ubude(%) | 15-25 | 12-20 |

| Inqubo yokukhiqiza | I-Pre-oxidation -Sintering-Extruding | |

5. Izinhlobo Zomkhiqizo

I-AgSnO2

1. Isakhiwo esincane

2. Incazelo Ejwayelekile

I-AgSnO2/AgSn021n203 izinto zokuxhumana zikagesi ezisebenziseka kalula.Banokusebenza okuhle kwezakhiwo ezilwa nokuguguleka kanye ne-anti-welding, futhi banempahla enhle yokudlulisa impahla kusekethe yokushintsha i-DC.Izinqubo eziyinhloko zokukhiqiza ziyinqubo ye-oxidation yangaphakathi, inqubo ye-pre-oxidation, inqubo ye-powder metallurgy, inqubo yokuhlanganisa amakhemikhali, njll..

3. Ububanzi Bokusebenza

Isetshenziswa kakhulu ezinhlotsheni ezahlukahlukene zoxhumana nabo, ama-relay, ama-circuit breaker namaswishi, njll.

4. Izinto ezibonakalayo

I-AgSnO2

| Izintambo | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | AgSn02 |

| Okuqukethwe kwe-SnO2 (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Ukuminyana (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Ukumelana (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Ubulukhuni HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Amandla Okuqina (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Ubude(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Inqubo yokukhiqiza | I-Pre-oxidation-Sintering-Extruding | I-Chemical Coating | Ukuxuba-Sintering-Extruding | ||

I-AgSnO2In203

| Izintambo | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 |

| Okuqukethwe kwe-Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Ukuminyana (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Ukungazweli (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Ubulukhuni HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Amandla Okuqina (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Ubude(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Inqubo yokukhiqiza | I-Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||

5. Izinhlobo Zomkhiqizo

I-AgSnO2In2O3

1. Incazelo Ejwayelekile

2. Isakhiwo esincane

I-AgSnO2lAgSn021n203 izinto zokuxhumana zikagesi ezisebenziseka kalula.Banokusebenza okuhle kwezakhiwo ezilwa nokuguguleka kanye ne-anti-welding, futhi banempahla enhle yokudlulisa impahla kusekethe yokushintsha i-DC.Izinqubo zokukhiqiza eziyinhloko ziyinqubo ye-oxidation yangaphakathi, inqubo ye-pre-oxidation, inqubo ye-powder metallurgy, inqubo yokuhlanganisa amakhemikhali, njll.

3. Ububanzi Bokusebenza

Isetshenziswa kakhulu ezinhlotsheni ezahlukahlukene zoxhumana nabo, ama-relay, ama-circuit breaker namaswishi, njll.

4. Izinto ezibonakalayo

I-AgSnO2

| Izintambo | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | AgSn02 |

| Okuqukethwe kwe-SnO2 (wt.%) | 10 ±1 | 10 ±1 | 12±1 | 12±1 | 15 ±1 |

| Ukuminyana (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Ukumelana (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Ubulukhuni HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Amandla Okuqina (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Ubude(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Inqubo yokukhiqiza | I-Pre-oxidation-Sintering-Extruding | I-Chemical Coating | Ukuxuba-Sintering-Extruding | ||

I-AgSnO2In203

| Izintambo | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 | I-AgSnO2 |

| Okuqukethwe kwe-Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Ukuminyana (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Ukumelana (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Ubulukhuni HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Amandla Okuqina (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Ubude(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Inqubo yokukhiqiza | I-Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||