OKUXHUMANA NEMETALI YOPHUVA

| Isicelo: |

| Oxhumana nabo, ama-circuit breaker, ama-thermostat, amaswishi ahlakaniphile, njll |

| Okubalulekile: |

| I-AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

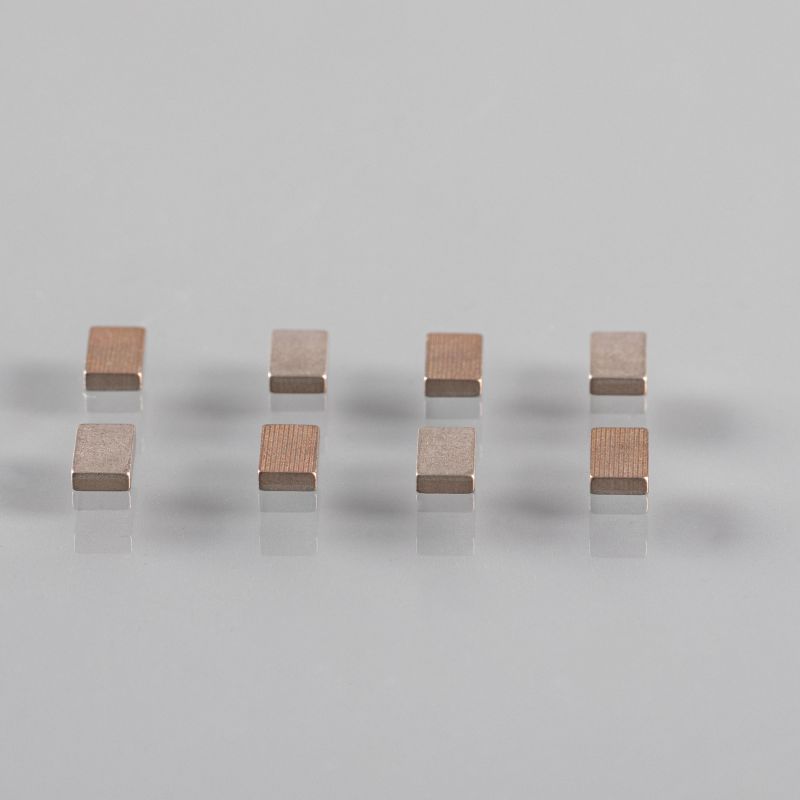

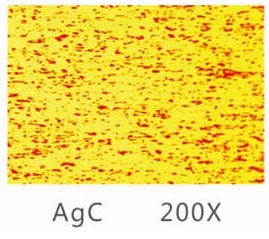

I-AgC

I-Microstructure

Incazelo evamile

Izinto zokuxhumana ze-AgC zibonisa ukumelana okuphezulu kakhulu nokushisela othintana naye kanye nokumelana nokuxhumana okuphansi.Ukumelana nokushisela kuyanda ngokwanda kokuqukethwe kwe-graphite.Izinto ze-AgC zinokuzithambisa uma zisetshenziswa njengoxhumana nabo abaslayidayo.

Ububanzi bohlelo lokusebenza

Isetshenziswa kakhulu ekushintsheni okuvikelayo okufana nama-MCB, ama-MCCB, amaswishi okuvikela amanje ayinsalela, noma amaswishi okuvikela izimoto.Uhlelo lokusebenza luvamise ukufana ne-AgNi, AgW, AgWC noma i-Cu.

Izinto ezibonakalayo

| I-AgC | I-AgC | I-AgC | I-AgC | I-AgC | I-AgC | |

| C Okuqukethwe(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Ukuminyana (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| I-Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Ubulukhuni HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Inqubo yokukhiqiza | I-Sintering-Extruding | |||||

Izinhlobo Zomkhiqizo

I-AgW

I-Microstructure

Incazelo evamile

Othintana nabo abenziwe nge-AgW babonisa ukumelana okuphezulu kwe-anti-welding kanye nokumelana okuphezulu nokuguguleka kwe-arc ngenxa yezinga eliphezulu lokuncibilika kanye nobulukhuni obuphezulu be-W, futhi banokusebenza okuhle kukagesi nokushisayo.

Ububanzi bohlelo lokusebenza

Izinto ze-AgW zisetshenziswa kakhulu ku-low voltage MCCB kanye ne-ACB kanye namaswishi okuvikela.

Izinto ezibonakalayo

| I-AgW | I-AgW | I-AgW | I-AgW | I-AgW | I-AgW | |

| Okuqukethwe kwe-Ag(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Ukuminyana (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| I-EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Ubulukhuni HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Inqubo yokukhiqiza | Ukungena | |||||

Izinhlobo Zomkhiqizo

I-AgWC

I-Microstructure

Incazelo evamile

Izinto zokuxhumana ze-AgWC eziqukethe ingxenye ye-WC ephikisayo zinobulukhuni obuphezulu kanye nokumelana nokugqokwa komshini, ukuthambekela okuphansi kokushisela othintana naye, kanye nokumelana nokuxhumana okuzinzile kusevisi.Oxhumana nabo be-AgWC bakhiqizwa ukungena kwe-powder metallurgy.

Ububanzi bohlelo lokusebenza

Isetshenziswa kakhulu kumadivayisi okushintsha umsebenzi osindayo, njengama-circuit breaker.ama-circuit breaker asele.Ezimweni eziningi asetshenziswa ku-asymmetric match ne-AgC

Izinto ezibonakalayo

| I-AgWC | I-AgWC | I-AgWC | I-AgWC | |

| Okuqukethwe kwe-Ag(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Ukuminyana (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| I-Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Ubulukhuni HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Inqubo yokukhiqiza | Ukungena | |||

Izinhlobo Zomkhiqizo

AgWCC

I-Microstructure

Incazelo evamile

Ngenxa yokuqukethwe okuphezulu kwe-Ag , abathintwayo be-AgWCC banokumelana okuphansi kokuxhumana.Zinezinto eziphakeme kakhulu zokulwa nokushisela ngenxa yokuqukatha i-tungsten carbide ne-graphite enephuzu eliphezulu lokuncibilika.Oxhumana nabo be-AgWCC bakhiqizwa ngokufaka i-sintering.

Ububanzi bohlelo lokusebenza

Isetshenziswa kakhulu kumadivayisi okushintsha umsebenzi osindayo, njengama-circuit breaker.ama-circuit breaker asele.Ezimweni eziningi asetshenziswa kumdlalo we-asymmetric ne-AgNi, AgW noma i-AgWC.

Izinto ezibonakalayo

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Okuqukethwe kwe-Ag(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Ukuminyana (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| I-Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Ubulukhuni HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Inqubo yokukhiqiza | Mixing-Compacting-Sintering | |||

Izinhlobo Zomkhiqizo

I-AgNiC

I-Microstructure

Incazelo evamile

Oxhumana nabo be-AgNiC bahlanganisa izinzuzo zoxhumana nabo be-AgNi ne-AgC.Ziyakwazi ukumelana kahle nokuguguleka kukagesi kanye nezakhiwo zokulwa nokushisela.

Ububanzi bohlelo lokusebenza

Oxhumana nabo be-AgNiC basetshenziswa kakhulu ku-MCCB, ACB.

Izinto ezibonakalayo

| I-AgNiC | I-AgNiC | 3AgNiC | |

| Okuqukethwe kwe-Ag(wt.%) | 67±1 | 73±1 | 94±1 |

| Ukuminyana (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| I-Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Ubulukhuni HV | ≥50 | ≥60 | ≥30 |

| Inqubo yokukhiqiza | Mixing-Compacting-Sintering | ||

Izinhlobo Zomkhiqizo

KuW

I-Microstructure

Incazelo evamile

Izinto zokuxhumana ze-CuW zinokumelana okuhle kakhulu nokuguguleka kwe-arc kanye nezakhiwo ezilwa nokushisela kuze kufike ku-curret ephezulu kakhulu.Oxhumana nabo be-CuW bakhiqizwa ngezindlela ezihlukahlukene kakhulu ngokusebenzisa i-powder metallurgy (ukucindezela / ukucwiliswa noma ukungena ngaphakathi).Okuqukethwe kwe-tungsten kungu-50% -80%.

Ububanzi bohlelo lokusebenza

Oxhumana nabo beCuW basetshenziswa kakhulu kuma-switchgear aphakathi nendawo naphezulu.Izinhlelo zokusebenza ezijwayelekile ziku-high voltage circuit breaker, izishintshi zokulayisha, iziguquli zokushintsha umpompi zokushintsha kanye noxhumana nabo be-arc voltage ephansi.

Ngaphezu kwalokho, izinto ze-CuW zisetshenziswa kabanzi njengama-electrode, ikakhulukazi ukushisela.

Izinto ezibonakalayo

| KuW | KuW | KuW | |

| Okuqukethwe kwe-Cu (wt.%) | 50±2 | 40±2 | 30±2 |

| Ukuminyana (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| I-EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Ubulukhuni HV | ≥115 | ≥140 | ≥175 |

| Inqubo yokukhiqiza | Ukungena | ||

Izinhlobo Zomkhiqizo