Njengoba ukudluliselwa kuyizingxenye zokulawula ezivame ukusetshenziswa kakhulu ekulawuleni okuzenzakalelayo okungajwayelekile, kubalulekile ukuqondaedluliselwe contact materialsneminyaka yokuphila.Ukukhetha ama-relay anezinto zokuxhumana ezifanele kanye neminyaka yokuphila isikhathi eside kunganciphisa izindleko zokulungisa kanye namazinga aphansi okuhluleka kwemishini.

Inhloso evamile kanye nokudluliselwa kwamandla kuvamise ukuba nesikhathi sokuphila sikagesi okungenani sokusebenza okungu-100,000, kuyilapho ubude bempilo bomshini bungaba ngu-100,000, 1,000,000 noma ngisho nemisebenzi eyizigidi eziyizinkulungwane ezingu-2.5.Isizathu sokuthi impilo kagesi ibephansi kakhulu uma iqhathaniswa nempilo yokusebenza ukuthi impilo yokuxhumana incike kuhlelo lokusebenza.Izilinganiso zikagesi zisebenza koxhumana nabo abashintsha imithwalo yabo elinganiselwe, futhi uma isethi yoxhumana nabo ishintsha umthwalo omncane kunokulinganisa, impilo yokuxhumana ingase ibe yinde kakhulu.Isibonelo, i-240A, 80V AC, 25% PF abathintwayo bangashintsha umthwalo ongu-5A emisebenzini engaphezu kuka-100,000.Kodwa-ke, uma laba othintana nabo besetshenziselwa ukushintsha (isb: 120A, 120VAC imithwalo eqinile), impilo ingase yeqe imisebenzi eyisigidi.Isilinganiso sempilo kagesi siphinde sicabangele ukulimala kwe-arc koxhumana nabo, futhi ngokusebenzisa ukucindezelwa kwe-arc okufanele, impilo yokuxhumana inganwetshwa.

Impilo yokuxhumana iyaphela lapho abathintwayo benamathela noma beshisela, noma lapho oyedwa noma bobabili othintana nabo belahlekelwa okokusebenza okudlulele futhi ukuthintana kahle kukagesi kungafinyelelwa, ngenxa yokudluliselwa kwezinto ezibonakalayo ngesikhathi sokushintshwa okuqhubekayo kanye nokulahlekelwa kwempahla ngenxa yokufafaza.

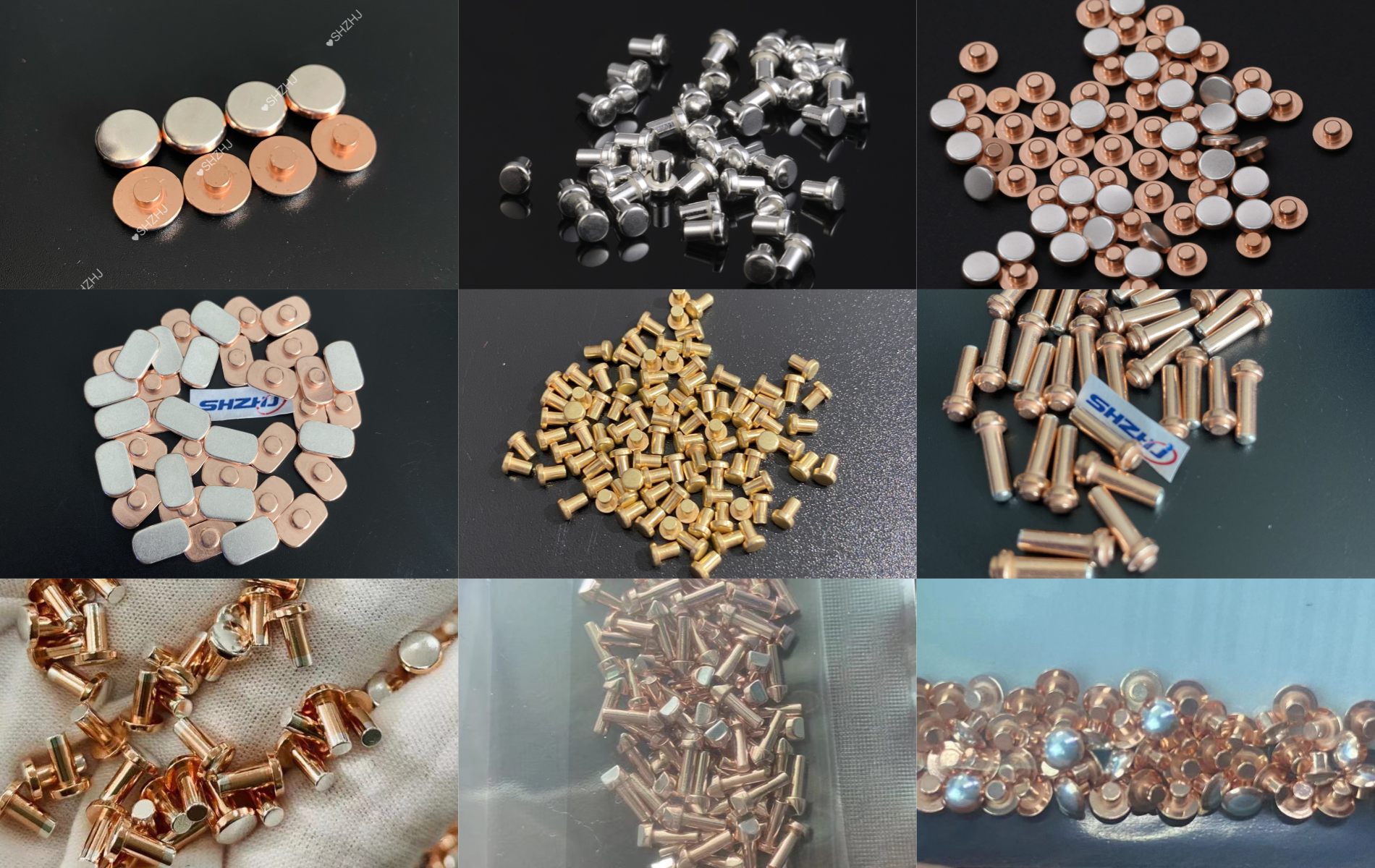

Oxhumana nabo be-relay batholakala ngezinhlobonhlobo eziningi zezinsimbi nama-alloys, osayizi nezitayela, futhi ukukhethwa koxhumana nabo kudinga ukucabangela impahla, isilinganiso nesitayela ukuze kuhlangatshezwane nezidingo zohlelo oluthile ngokunembe ngangokunokwenzeka.Ukwehluleka ukwenza kanjalo kungase kubangele izinkinga zokuxhumana noma ngisho nokwehluleka ukuthintana kwangaphambi kwesikhathi.

Ngokuya ngesicelo, oxhumana nabo bangenziwa ngama-alloys afana ne-palladium, iplatinamu, igolide, isiliva, isiliva-nickel, ne-tungsten.Ikakhulukazi ingxubevange yesiliva, isiliva cadmium oxide (I-AgCdOkanye nesiliva tin oxide (I-AgSnOkanye nesiliva i-idium tin oxide (I-AgInSnO) zisetshenziswa kabanzi kunhloso ejwayelekile kanye nokudluliselwa kwamandla okushintshashintshayo kwamanje okuphakathi nendawo ukuya kokuphezulu.

I-Silver Cadmium Oxide (AgCdO) isidume kakhulu ngenxa yokuguguleka kwayo okuhle kakhulu nokumelana ne-solder kanye nokuhamba kukagesi nokushisayo okuphezulu kakhulu. kanye nokumelana nokuxhumana okusondelene nalokhu kwesiliva (kusetshenziswa izingcindezi zokuthintana eziphakeme kancane), kodwa ngenxa yokumelana ne-solder ngokwemvelo kanye nezakhiwo zokucisha i-arc ye-cadmium oxide, inokuguguleka okuhle kakhulu nokumelana nokushisela.

Izinto zokuxhumana ezijwayelekile ze-AgCdO ziqukethe u-10 kuya ku-15% we-cadmium oxide, futhi ukunamathela noma ukumelana ne-solder kuyathuthuka ngokwanda kokuqukethwe kwe-cadmium oxide;kodwa-ke, ngenxa yokuncipha kwe-ductility, ukuhanjiswa kukagesi kuyehla, nezici zokusebenza ezibandayo ziyehla.

Oxhumana nabo besiliva be-cadmium oxide bane-post-oxidation noma i-pre-oxidation yezinhlobo ezimbili, i-oxidation yangaphambili yezinto ekwakhekeni kwendawo yokuxhumana yenziwe i-oxid ngaphakathi, futhi kunokuba i-oxidation ye-post-oxidation iqukethe ukusatshalaliswa okufanayo okufanayo kwe-cadmium. oxide, lokhu kwakamuva kuvame ukwenza i-cadmium oxide isondele endaweni yokuxhumana.Othintana nabo ngemuva kwe-oxidized bangabangela izinkinga zokuqhekeka kwendawo uma ukwakheka kokuxhumana kufanele kushintshwe kakhulu ngemva kwe-oxidation, isb, ama-double-end, ama-blade anyakazayo, ama-rivets ohlobo lwe-C.

I-Silver Indium Tin Oxide (AgInSnO) kanye ne-Silver Tin Oxide (AgSnO) seziphenduke izindlela ezinhle kunoxhumana nabo be-AgCdO, futhi ukusetshenziswa kwe-cadmium kothintana nabo namabhethri kukhawulelwe ezingxenyeni eziningi zomhlaba.Ngakho-ke, othintana nabo be-tin oxide (12%), okuqina ngo-15% kune-AgCdO, kuyisinqumo esihle.Ngaphezu kwalokho, othintana nabo be-silver-indium-tin oxide bafanele imithwalo ephezulu yokuhlinzwa, isb, izibani ze-tungsten, lapho isimo samanje esizinzile siphansi.Nakuba imelana kakhulu nokusoda, abathintwayo be-AgInSn kanye ne-AgSn banokumelana kwevolumu ephezulu (i-conductivity ephansi) kune-Ag ne-AgCdO abathintwayo.Ngenxa yokumelana ne-solder, othintana nabo abangenhla bathandwa kakhulu embonini yezimoto, lapho imithwalo ye-12VDC inductive ivame ukubangela ukudluliswa kwezinto ezibonakalayo kulezi zinhlelo zokusebenza.

Isikhathi sokuthumela: Apr-01-2024