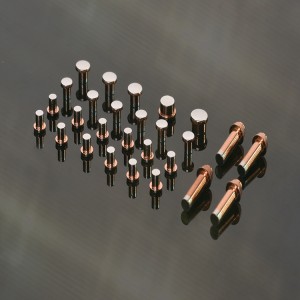

Bimetal Xhumana Rivet

Izici Zomkhiqizo

I-1.I-riveting eyinhlanganisela ephindwe kabili ilondoloza kahle izinsimbi eziyigugu futhi yehlise izindleko

2.thuthukisa ukusebenza kwe-rivet riveting yokuxhumana.

3.Faka ukukhiqizwa kwe-automation okuqhubekayo.

Isicelo Esiyinhloko

Imishini kagesi yemoto, izinto zasendlini, ukudlala kabusha, othintana naye,

I-Thermostat, zonke izinhlobo zokushintshwa, izinto zikagesi zezindiza, isibali sikhathi nezinto zikagesi.

Ukugeleza kwenqubo

Ukwenza i-Rivet

Anealing

Ukuqeda

Ukuhlola

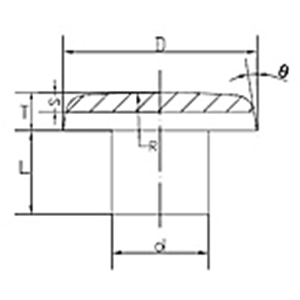

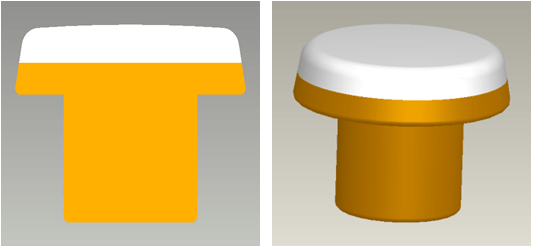

Umdwebo

Ukupakisha

Incazelo Yomkhiqizo:Banokusebenza okuhle kwezakhiwo ezilwa nokuguguleka kanye ne-anti-welding, futhi banempahla enhle yokudlulisa impahla kusekethe yokushintsha i-DC.Izinqubo zokukhiqiza eziyinhloko ziyinqubo ye-oxidation yangaphakathi, inqubo ye-pre-oxidation, inqubo ye-powder metallurgy, inqubo yokuhlanganisa amakhemikhali, njll. I-Silver Tin Oxide Bimetal Contact Rivets inezindleko eziphansi kunama-rivets aqinile.

Kala:

| Into | Ububanzi bekhanda D(mm) | Ukujiya kwekhanda T(mm) | Ububanzi besendlalelo S(mm) | Ububanzi be-Shank D(mm) | Ubude be-Shank L(mm) | I-Sphere radium SR(mm) | Isilinganiso sesikhunta8(▫) |

| specifl-cation | 2.5 | 0.6,0.8,1.0 | 0.3-0.4 | 1.2,1.5 | 1; 2 | 4,6 | 9 |

| 3.0 | 0.8,1.0,1.2 | 0.35-0.50 | 1.50 | 6,8 | |||

| 3.5 | 1.50,2.0 | 1; 3 | |||||

| 4.0 | 1.0,1.2,1.5 | 2.0 | 8,10 | ||||

| 4.5 | 2.0,2.5 | ||||||

| 5.0 | 1.0,1.2,1.5,2.0 | 0.40-0.60 | 2.5 | 10,15 | |||

| 5.5 | 2.5,3.0 | ||||||

| 6.0 | 3.0 | 15,20 | |||||

| 6.5 | 1.2,1.5,2.0 | 0.50-0.70 | 3.0,3.5 | ||||

| 7.0 | 3.5 | 20,25 | |||||

| 8.0 | 4.0 | ||||||

| ikhanda kanye ne-shank coaxiality | ±0.1 | ±0.05 | S≤0.4+0.6 S~0.4-0.06 | -0.02,-0.1 | +0.15 | ±0.2R | ±2 |