UQHAGAMSHELWANO LWE-POWDER MEtal

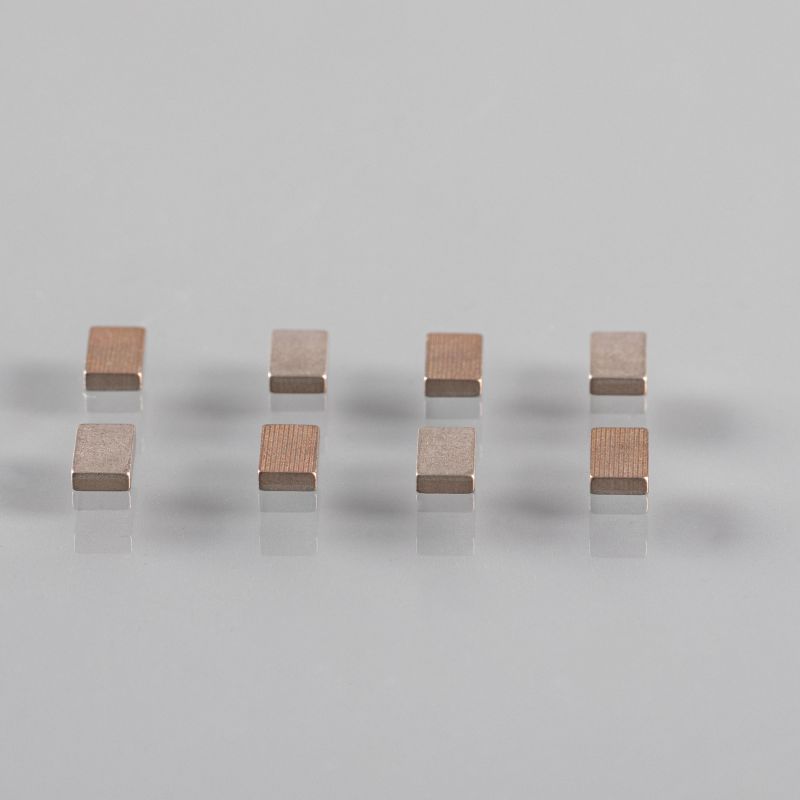

| Isicelo: |

| Abafowunelwa, ii-circuit breakers, thermostats, iiswitshi ezikrelekrele, njl |

| Isixhobo: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

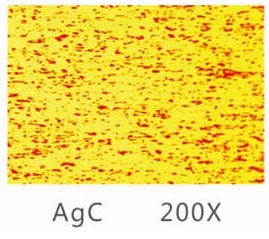

AgC

Microstructure

Inkcazo ngokubanzi

Izixhobo zoqhagamshelwano ze-AgC zibonisa ukuxhathisa okuphezulu kakhulu ngokuchasene ne-welding yoqhagamshelwano kunye nokumelana noqhagamshelwano oluphantsi.Ukuchasa ngokuchasene ne-welding kuyanda ngokunyuka komxholo wegraphite.Imathiriyeli ye-AgC inokuziphatha okuzithambisayo xa isetyenziswa njengabafowunelwa abatyibilikayo.

Umda wosetyenziso

Ikakhulu isetyenziswa kwizitshixo ezikhuselayo ezinje ngee-MCBs, ii-MCCBs, iiswitshi ezishiyekileyo zokhuseleko lwangoku, okanye iiswitshi zokukhusela iimoto.Isicelo siqhelekile kumdlalo we-asymmetric kunye ne-AgNi, AgW, AgWC okanye Cu.

Iimpahla zeMathiriyeli

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Umxholo(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Ubuninzi (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Ubulukhuni HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Inkqubo yokuvelisa | Sintering-Extruding | |||||

Iintlobo zeeMveliso

AgW

Microstructure

Inkcazo ngokubanzi

Abafowunelwa be-AgW babonisa ukuchasana okuphezulu kwe-welding kunye nokuchasana okuphezulu kwi-arc erosion ngenxa yeqondo eliphezulu lokunyibilika kunye nobunzima obuphezulu be-W, nabo banombane kunye ne-thermal conductivity.

Umda wosetyenziso

Izinto ze-AgW zisetyenziswa ikakhulu kumbane ophantsi we-MCCB kunye ne-ACB kunye nokutshintsha okukhuselekileyo.

Iimpahla zeMathiriyeli

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Umxholo we-Ag(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Ubuninzi (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Ubulukhuni HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Inkqubo yokuvelisa | Ukungeniswa | |||||

Iintlobo zeeMveliso

AgWC

Microstructure

Inkcazo ngokubanzi

Izixhobo zoqhagamshelwano ze-AgWC eziqulathe icandelo le-WC zinobulukhuni obuphezulu kunye nokuxhathisa ukunxitywa koomatshini, utyekelo oluphantsi malunga ne-welding yokudibanisa, kunye nokumelana nokunxibelelana okuzinzileyo enkonzweni.Abafowunelwa be-AgWC iveliswa ngokungeniswa komgubo wesinyithi.

Umda wosetyenziso

Ikakhulu isetyenziswa kwizixhobo zokutshintsha izinto ezinzima, ezinje ngabaphuli beesekethe.ii-breakers zangoku ezishiyekileyo.Kwiimeko ezininzi zisetyenziswa kumdlalo we-asymmetric kunye ne-AgC

Iimpahla zeMathiriyeli

| AgWC | AgWC | AgWC | AgWC | |

| Umxholo we-Ag(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Ubuninzi (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Ubulukhuni HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Inkqubo yokuvelisa | Ukungeniswa | |||

Iintlobo zeeMveliso

AgWCC

Microstructure

Inkcazo ngokubanzi

Ngenxa yomxholo we-Ag ephezulu, abafowunelwa be-AgWCC banokunganyangeki okuphantsi.Zineempawu ezichasene ne-welding ephezulu kakhulu ngenxa yokuqulatha i-tungsten carbide kunye negraphite enendawo ephezulu yokunyibilika.Abafowunelwa be-AgWCC benziwa ngokucolwa.

Umda wosetyenziso

Ikakhulu isetyenziswa kwizixhobo zokutshintsha izinto ezinzima, ezinje ngabaphuli beesekethe.ii-breakers zangoku ezishiyekileyo.Kwiimeko ezininzi zisetyenziswa kumdlalo we-asymmetric kunye ne-AgNi, i-AgW okanye i-AgWC.

Iimpahla zeMathiriyeli

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Umxholo we-Ag(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Ubuninzi (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Ubulukhuni HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Inkqubo yokuvelisa | Ukuxuba-Compacting-Sintering | |||

Iintlobo zeeMveliso

AgNiC

Microstructure

Inkcazo ngokubanzi

Abafowunelwa be-AgNiC badibanisa iingenelo ze-AgNi kunye ne-AgC yabafowunelwa.Banokuchasana kakuhle nokukhukuliseka kombane kunye neempawu ezichasene ne-welding.

Umda wosetyenziso

Abafowunelwa be-AgNiC basetyenziswa kakhulu kwi-MCCB, ACB.

Iimpahla zeMathiriyeli

| AgNiC | AgNiC | 3AgNiC | |

| Umxholo we-Ag(wt.%) | 67±1 | 73±1 | 94±1 |

| Ubuninzi (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Ubulukhuni HV | ≥50 | ≥60 | ≥30 |

| Inkqubo yokuvelisa | Ukuxuba-Compacting-Sintering | ||

Iintlobo zeeMveliso

CuW

Microstructure

Inkcazo ngokubanzi

Izixhobo zoqhagamshelwano ze-CuW zinokuxhathisa okugqwesileyo ngokuchasene nokhukuliseko lwe-arc kunye neempawu ezichasene ne-welding ukuya kuthi ga kwi-curret ephezulu kakhulu.Uqhagamshelwano lweCuW luveliswa kwiimilo ezininzi ezahlukeneyo ngomgubo wesinyithi (ucofa / ukuntywila okanye ukungena ngaphakathi).Umxholo we-tungsten ngu-50% -80%.

Umda wosetyenziso

Abafowunelwa beCuW basetyenziswa ikakhulu kwisixhobo sokutshintsha amandla ombane aphakathi naphezulu.Usetyenziso oluqhelekileyo lukwizaphuli zesekethe zombane ophezulu, izitshixo zomthwalo, iziguquli zokutshintsha itephu zokutshintsha amandla ombane kunye nabafowunelwa be-arcing yombane ophantsi.

Ukongeza, izixhobo zeCuW zisetyenziswa ngokubanzi njengee-electrode, ngokuyintloko kwi-welding.

Iimpahla zeMathiriyeli

| CuW | CuW | CuW | |

| Cu Umxholo (wt.%) | 50±2 | 40±2 | 30±2 |

| Ubuninzi (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Ubulukhuni HV | ≥115 | ≥140 | ≥175 |

| Inkqubo yokuvelisa | Ukungeniswa | ||

Iintlobo zeeMveliso