Njengoko ii-relays ziyizona nxalenye zolawulo ezisetyenziswa ngokuqhelekileyo kulawulo oluzenzekelayo olungenamgangatho, kubalulekile ukuqondaunxibelelwano lwezixhobo zonxibelelwanokunye neminyaka elindelekileyo yokuphila.Ukukhetha iireyidi ezinemathiriyeli efanelekileyo yoqhagamshelwano kunye nexesha elide lokuphila kunokunciphisa iindleko zokulondolozwa kunye namazinga aphantsi okusilela kwezixhobo.

Injongo ngokubanzi kunye nokuhanjiswa kwamandla ngokuqhelekileyo kunobomi obulindelekileyo bombane ubuncinane be-100,000 yokusebenza, ngelixa ubomi bokusebenza koomatshini bunokuba yi-100,000, 1,000,000 okanye i-2.5 yeebhiliyoni zokusebenza.Isizathu sokuba ubomi bombane buphantsi kakhulu xa kuthelekiswa nobomi boomatshini kukuba ubomi bonxibelelwano buxhomekeke kwisicelo.Ukulinganisa kombane kusebenza kubafowunelwa abatshintsha imithwalo yabo elinganisiweyo, kwaye xa isethi yabafowunelwa itshintshela umthwalo omncinci kunokulinganisa, ubomi boqhagamshelwano bunokuba bude kakhulu.Ngokomzekelo, i-240A, i-80V AC, i-25% yabafowunelwa be-PF inokutshintsha umthwalo we-5A kwimisebenzi engaphezu kwe-100,000.Nangona kunjalo, ukuba aba bafowunelwa basetyenziselwa ukutshintsha (umzekelo: i-120A, i-120VAC imithwalo yokumelana), ubomi bunokugqithisa imisebenzi yesigidi esinye.Ukulinganisa ubomi bombane kwakhona kuthathela ingqalelo umonakalo we-arc kubafowunelwa, kwaye ngokusebenzisa ukunyanzeliswa kwe-arc efanelekileyo, ubomi boqhagamshelwano bunokwandiswa.

Ubomi boqhagamshelwano buphela xa abafowunelwa benamathela okanye be-weld, okanye xa omnye okanye bobabini abafowunelwa belahlekelwa yimpahla eninzi kunye noqhagamshelwano olulungileyo lombane alukwazi ukufezekiswa, ngenxa yokudluliselwa kwezinto eziphathekayo ngexesha lokutshintsha okuqhubekayo kunye nokulahlekelwa kwezinto ngenxa yokutshiza.

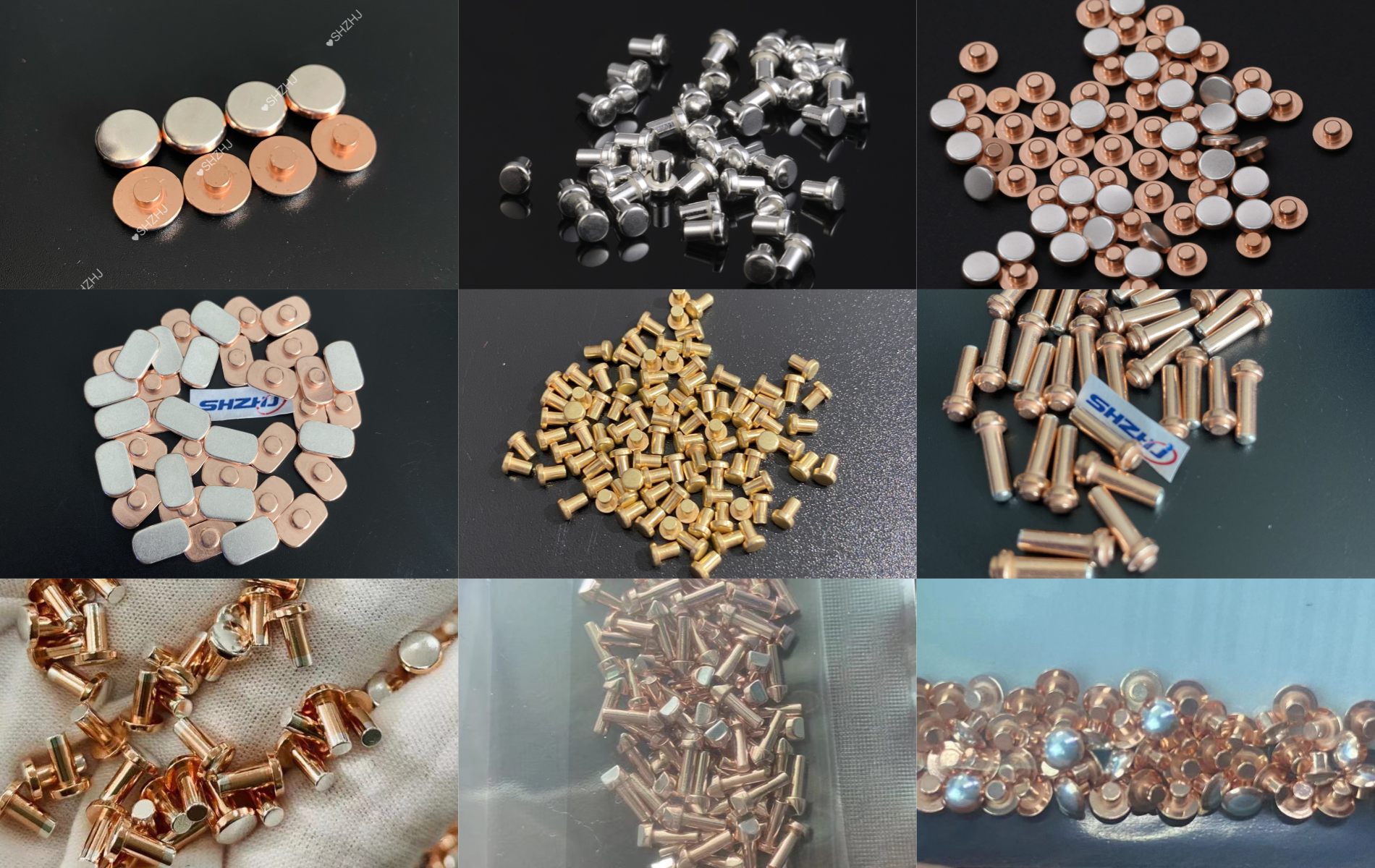

Abafowunelwa be-Relay bafumaneka kuluhlu olubanzi lweetsimbi kunye ne-alloys, ubukhulu kunye nezitayela, kwaye ukukhethwa kwabafowunelwa kufuneka kuthathelwe ingqalelo kwizinto eziphathekayo, ukulinganisa kunye nesitayela ukwenzela ukuhlangabezana neemfuno zesicelo esithile ngokuchanekileyo ngokunokwenzeka.Ukungaphumeleli ukwenza oko kunokubangela iingxaki zoqhagamshelwano okanye ukusilela koqhagamshelwano kwangethuba.

Ngokuxhomekeke kwisicelo, unxibelelwano lunokwenziwa kunye ne-alloys ezifana ne-palladium, iplatinam, igolide, isilivere, isilivere-nickel, kunye ne-tungsten.Ubukhulu becala iikhompawundi zealloyi yesilivere, isilivere yecadmium oxide (AgCdO) kunye nesilivere yetin oxide (AgSnO) kunye nesilivere ye-idium tin oxide (AgInSnO) zisetyenziswa ngokubanzi kwinjongo jikelele kunye nokuhanjiswa kwamandla okutshintsha okuphakathi ukuya phezulu.

I-Silver Cadmium Oxide (AgCdO) iye yaduma kakhulu ngenxa yokhukuliseko olugqwesileyo kunye nokumelana ne-solder kunye nokuphezulu kakhulu kombane kunye ne-thermal conductivity. kunye nokumelana nokunxibelelana kufutshane naleyo yesilivere (usebenzisa uxinzelelo lonxibelelwano oluphezulu kancinci), kodwa ngenxa yokumelana nendalo ye-solder kunye neempawu zokucima i-arc ye-cadmium oxide, inokhukuliseko olugqwesileyo kunye nokuxhathisa ukuwelda.

Izinto eziqhelekileyo zoqhagamshelwano ze-AgCdO ziqulethe i-10 ukuya kwi-15% ye-cadmium oxide, kwaye ukunamathela okanye ukuxhathisa i-solder kuphucula ngokunyuka komxholo we-cadmium oxide;nangona kunjalo, ngenxa yokunciphisa i-ductility, i-conductivity yombane iyancipha, kunye neempawu zokusebenza ezibandayo ziyancipha.

Uqhagamshelwano lwesilivere ye-cadmium oxide ine-post-oxidation okanye i-pre-oxidation yeentlobo ezimbini, i-oxidation yangaphambili yezinto ezibonakalayo ekubunjweni kwendawo yoqhagamshelwano iye yafakwa ngaphakathi ngaphakathi, kwaye kunokuba i-oxidation ye-post-oxidation iqulethe ukusabalalisa okufanayo kwe-cadmium. oxide, le yokugqibela ithande ukwenza i-cadmium oxide isondele kumphezulu woqhagamshelwano.I-post-oxidized contacts inokubangela iingxaki zokuqhekeka kwendawo ukuba i-shape contact shape kufuneka iguqulwe kakhulu emva kwe-oxidation, umzekelo, i-double-end, i-blades ehambayo, i-C-type contact rivets.

ISilver Indium Tin Oxide (AgInSnO) kunye neSilver Tin Oxide (AgSnO) ziye zaba zezinye iindlela ezilungileyo kuqhagamshelwano lwe-AgCdO, kwaye ukusetyenziswa kwe-cadmium kuqhagamshelwano nakwiibhetri kuthintelwe kwiindawo ezininzi zehlabathi.Ke ngoko, abafowunelwa be-tin oxide (12%), abanzima nge-15% kune-AgCdO, lukhetho olulungileyo.Ukongeza, i-silver-indium-tin oxide contacts ifanelekile kwimithwalo ephezulu yokunyuka, umz.Nangona ixhathisa ngakumbi ekuthengiseni, abafowunelwa be-AgInSn kunye ne-AgSn banokuxhathisa umthamo ophezulu (i-conductivity ephantsi) kune-Ag kunye ne-AgCdO yabafowunelwa.Ngenxa yokumelana ne-solder, abafowunelwa abangentla bathandwa kakhulu kwishishini leemoto, apho imithwalo ye-12VDC inductive ivame ukubangela ukuhanjiswa kwezinto kwezi zicelo.

Ixesha lokuposa: Apr-01-2024