Bimetal Qhagamshelana Rivet

Iimpawu zeMveliso

I-1.I-riveting edibeneyo edibeneyo igcina ngokufanelekileyo isinyithi esixabisekileyo kunye nokunciphisa iindleko

2.ukuphucula i-rivet riveting yoqhagamshelwano.

3.Faka imveliso eqhubekayo yokuzenzekelayo.

Isicelo esingundoqo

Izixhobo zombane zemoto, izixhobo zasekhaya, iireplays, umqhagamshelwa,

I-Thermostat, zonke iintlobo zokutshintsha, izixhobo zenqwelomoya, ixesha kunye nezixhobo zombane.

Ukuhamba kwenkqubo

Ukwenza iRivet

Ukuhlaziya

Ukugqiba

Ukuhlolwa

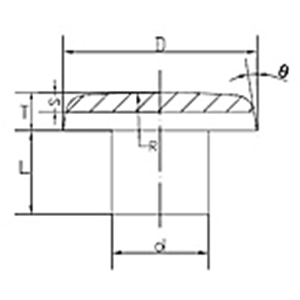

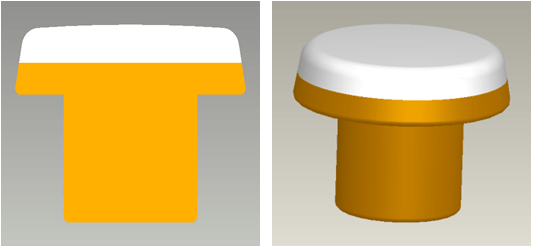

Umzobo

Ukupakisha

Ingcaciso yeMveliso:Banemisebenzi emihle kwi-anti-rosion kunye ne-anti-welding properties, kwaye banepropathi efanelekileyo yokudlulisa impahla kwi-DC switching circuit.Iinkqubo eziphambili zokuvelisa yinkqubo ye-oxidation yangaphakathi, inkqubo ye-oxidation yangaphambili, inkqubo ye-powder metallurgy, inkqubo yokugubungela iikhemikhali, njl njl.

Umlinganiselo:

| Into | Idayamitha yentloko D(mm) | Ubunzima bentloko T(mm) | umaleko wedayamitha S(mm) | Idayamitha yeShank D(mm) | Ubude beShank L(mm) | ISphere radium SR(mm) | Umlinganiselo wokungunda8(▫) |

| specifl-cation | 2.5 | 0.6,0.8,1.0 | 0.3-0.4 | 1.2,1.5 | 1~2 | 4,6 | 9 |

| 3.0 | 0.8,1.0,1.2 | 0.35 ~ 0.50 | 1.50 | 6,8 | |||

| 3.5 | 1.50,2.0 | 1~3 | |||||

| 4.0 | 1.0,1.2,1.5 | 2.0 | 8,10 | ||||

| 4.5 | 2.0,2.5 | ||||||

| 5.0 | 1.0,1.2,1.5,2.0 | 0.40 ~ 0.60 | 2.5 | 10,15 | |||

| 5.5 | 2.5,3.0 | ||||||

| 6.0 | 3.0 | 15,20 | |||||

| 6.5 | 1.2,1.5,2.0 | 0.50 ~ 0.70 | 3.0,3.5 | ||||

| 7.0 | 3.5 | 20,25 | |||||

| 8.0 | 4.0 | ||||||

| intloko kunye ne-shank coaxiality | ±0.1 | ±0.05 | S≤0.4+0.6 S>0.4-0.06 | -0.02,-0.1 | + 0.15 | ±0.2R | ±2 |