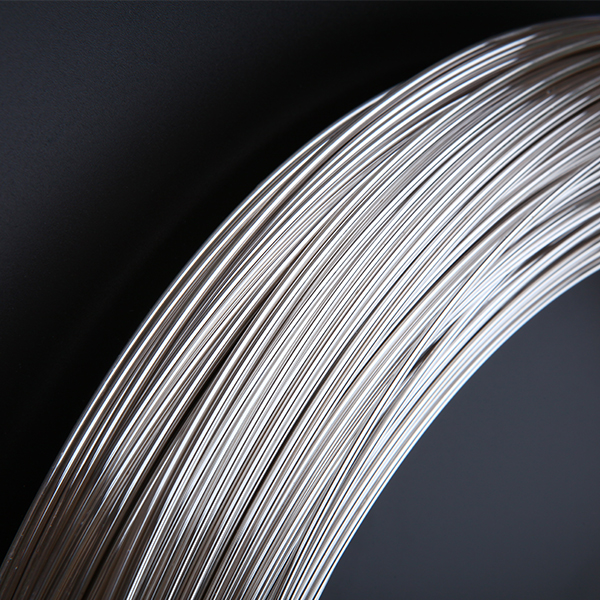

Silver Alloy Wires

| Kopo: |

| Li-contact, li-circuit breaker, li-thermostats, li-switches tse bohlale, joalo-joalo |

| Thepa: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Microstructure

2. Tlhaloso e Akaretsang

Silevera le silevera e ntle ea lijo-thollo (FAg) e na le matla a phahameng haholo a motlakase le a mocheso, khanyetso e tlase le e tsitsitseng ea ho kopana, le ts'ebetso e ntle ea ts'ebetso.Bakeng sa ho hanyetsa ha silevera ho khoholeho ea arc le ho kopana le welding ho fokotsehile, matla a mochine a fokotsehile, Ka lebaka la palo e nyenyane ea nickel ka silevera e ntle ea lijo-thollo, ho hanyetsa khoholeho ea arc le matla a mochine a phahame ho feta a silevera.

3. Sebaka sa Kopo

E sebelisoa haholo lisebelisoa tsa hajoale tse tlase, joalo ka li-relay, li-timers, li-switches tse thusang bakeng sa lisebelisoa tsa lapeng, li-switches tsa taolo, jj.

4. Thepa Thepa

| Ag | FAg | |||

| Malebela | Lithapo | Malebela | Lithapo | |

| Litaba tsa Ag (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Boima ba 'mele (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Resistivity (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Bothata ba HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Tensile Strength (MPa) |

| 230-380 |

| 250-380 |

| Elongation (%) |

| 2-30 |

| 2-30 |

| Mokhoa oa tlhahiso | Extruding-Rolling | Ho ntsha - Ho taka | Extruding-Rolling | Ho ntsha - Ho taka |

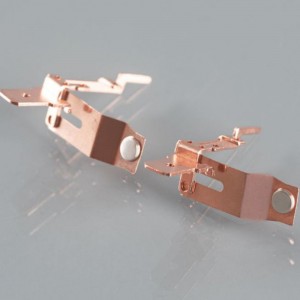

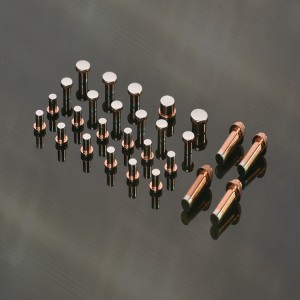

5. Mefuta ea Lihlahisoa

AgNi

1. Microstructure

2. Tlhaloso e Akaretsang

Lisebelisoa tsa AgNi li na le khanyetso e phahameng ea khoholeho ea arc le ho kopana le welding ho feta Ag kapa FAg.Thepa ka bobeli e ntlafatsoa ka litaba tse ntseng li eketseha tsa Ni.Lisebelisoa tsohle tsa AgNi li bonts'a ts'ebetso e ntle 'me ho bonolo ho li tjheseletsa ho ikopanya le litšehetso.Tloaelo e tlase ea phetisetso ea thepa lits'ebetsong tsa DC.Lisebelisoa tsa AgNi ke lisebelisoa tse sireletsang tikoloho.

3. Sebaka sa Kopo

Lisebelisoa tsa ho ikopanya le AgNi li fumana mefuta e mengata ea ts'ebeliso ho lisebelisoa tse feto-fetohang tsa motlakase o tlase.Li sebelisoa ho li-relay, li-contact tse nyane, li-switches tse bobebe, lilaoli tsa mocheso hammoho le li-switches tse sireletsang (li sebelisoa ka lipara tsa ho kopana tse sa tšoaneng, mohlala, khahlanong le thepa ea AgC, AgZnO kapaAgSnO2).

4. Thepa Thepa

| Lithapo | AgNi | AgNi | AgNi | Ag Ke | AgN ke | AgNi |

| Ke Content (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Boima ba 'mele (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Bothata ba HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Tensile Strength (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Elongation(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Mokhoa oa tlhahiso | Sintering-Extruding | |||||

5. Mefuta ea Lihlahisoa

AgCdO

1. Microstructure

2. Tlhaloso e Akaretsang

Mabitso a AgCdO ke a sehlopha sa tse sebelisoang haholo sebakeng sa lisebelisoa tsa motlakase tse tlase.Li kopanya khanyetso e khotsofatsang khahlano le welding ea khokahano le khanyetso e ntle ea khoholeho ea arc le khanyetso e tlase ea ho ikopanya le bophelo ba eona bo felletseng ba ts'ebeletso.Li hlahisoa ka mekhoa e 'meli e fapaneng, pre-oxidation-sintering-extruding le oxidation ea ka hare.Maemong ana ka bobeli, litaba tsa Cd0 li ka tloha ho 10 ho isa ho 20wt.. Leha ho le joalo, Cd le Cd0 li nkoa li le kotsi bophelong le tikolohong.Ka lebaka lena ts'ebeliso ea thepa ea AgCdO e tla thibeloa linaheng tse 'maloa.

3. Sebaka sa Kopo

E sebelisoa haholo hoo e batlang e le mofuta o mong le o mong oa lisebelisoa tsa ho fetola motlakase o tlase.Hangata li sebelisoa ho li-microswitches, li-relay, li-switches tse khanyang, likhokahano, li-switches tsa lisebelisoa tsa ntlo, mefuta e meng ea li-switch tse sireletsang, hammoho le mefuta e itseng ea li-circuit breakers.

4. Thepa Thepa

| Lithapo | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| CdO Content(wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Boima ba 'mele (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Bothata ba HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Tensile Strength (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Elongation(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Mokhoa oa tlhahiso | Pre-oxidation-Sintering-Extruding | Ka hare ho Oxidation | |||||

5. Mefuta ea Lihlahisoa

AgZnO

1. Microstructure

2. Tlhaloso e Akaretsang

Khanyetso e phahameng khahlano le welding ea ho ikopanya e tšoaea lisebelisoa tsa AgZnO.Li boetse li bontša khanyetso e ntle khahlanong le khoholeho ea arc.Khanyetso ea khokahano ea AgZnO e batla e phahame ho feta ea AgCd0.AgZnO e ka hlahisoa ka mokhoa oa pre-oxidation-sintering — extruding, mixing-compacting-sintering techniques hammoho le ka hare ho oxidation.Lisebelisoa tsa AgZnO ke lisebelisoa tse sireletsang tikoloho.

3. Sebaka sa Kopo

E sebelisoa haholo ho li-circuit breakers, haholo-holo ho li-circuit breakers.Likarolo tse ling tsa ts'ebeliso ke li-switches tse sireletsang enjene, li-circuits tsa morao-rao tse setseng le li-relay tsa AC.

4. Thepa Thepa

| Lithapo | AgZnO | AgZnO |

| Litaba tsa ZnO(wt.%) | 8±1 | 10±1 |

| Boima ba 'mele (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Bothata ba HV | E30 | 85 |

| Tensile Strength (MPa) | 285-350 | 285-350 |

| Elongation(%) | 15-25 | 12-20 |

| Mokhoa oa tlhahiso | Pre-oxidation -Sintering-Extruding | |

5. Mefuta ea Lihlahisoa

AgSnO2

1. Microstructure

2. Tlhaloso e Akaretsang

AgSnO2/AgSn021n203 ke lisebelisoa tsa ho ikopanya le motlakase tse sebetsang hantle.Ba na le ts'ebetso e ntle ea thepa e khahlanong le khoholeho ea mobu le e khahlanong le welding, 'me ba na le thepa e ntle ea ho fetisa thepa ho DC switching circuit.Mekhoa ea mantlha ea tlhahiso ke ts'ebetso ea ka hare ea oxidation, ts'ebetso ea pele ho oxidation, ts'ebetso ea metallurgy ea phofo, ts'ebetso ea ho roala lik'hemik'hale, joalo-joalo..

3. Sebaka sa Kopo

E sebelisoa haholo mefuteng e fapaneng ea likhokahano, li-relay, li-circuit breaker le li-switches, jj.

4. Thepa Thepa

AgSnO2

| Lithapo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Litaba tsa SnO2 (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Boima ba 'mele (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistivity (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Bothata ba HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile Strength (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Mokhoa oa tlhahiso | Pre-oxidation-Sintering-Extruding | Ho roala ka lik'hemik'hale | Kopanya-Sintering-Extruding | ||

AgSnO2In203

| Lithapo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Litaba tsa Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Boima ba 'mele (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Resistivity (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Bothata ba HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile Strength (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Mokhoa oa tlhahiso | Pre-oxidation-Sintering-Extruding | Ka hare ho Oxidation | |||

5. Mefuta ea Lihlahisoa

AgSnO2In2O3

1. Tlhaloso e Akaretsang

2. Microstructure

AgSnO2lAgSn021n203 ke lisebelisoa tsa ho ikopanya le motlakase tse sebetsang hantle.Ba na le ts'ebetso e ntle ea thepa e khahlanong le khoholeho ea mobu le e khahlanong le welding, 'me ba na le thepa e ntle ea ho fetisa thepa ho DC switching circuit.Mekhoa ea mantlha ea tlhahiso ke ts'ebetso ea ka hare ea oxidation, ts'ebetso ea pre-oxidation, ts'ebetso ea metallurgy ea phofo, ts'ebetso ea ho roala lik'hemik'hale, joalo-joalo.

3. Sebaka sa Kopo

E sebelisoa haholo mefuteng e fapaneng ea likhokahano, li-relay, li-circuit breaker le li-switches, jj.

4. Thepa Thepa

AgSnO2

| Lithapo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Litaba tsa SnO2 (wt.%) | 10 ±1 | 10 ±1 | 12±1 | 12±1 | 15 ±1 |

| Boima ba 'mele (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Ho hanyetsa (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Bothata ba HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile Strength (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Mokhoa oa tlhahiso | Pre-oxidation-Sintering-Extruding | Ho roala ka lik'hemik'hale | Kopanya-Sintering-Extruding | ||

AgSnO2In203

| Lithapo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Litaba tsa Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Boima ba 'mele (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Ho hanyetsa (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Bothata ba HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile Strength (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Mokhoa oa tlhahiso | Pre-oxidation-Sintering-Extruding | Ka hare ho Oxidation | |||