TS'ELISO PHOOPHO

| Kopo: |

| Li-contact, li-circuit breaker, li-thermostats, li-switches tse bohlale, joalo-joalo |

| Thepa: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

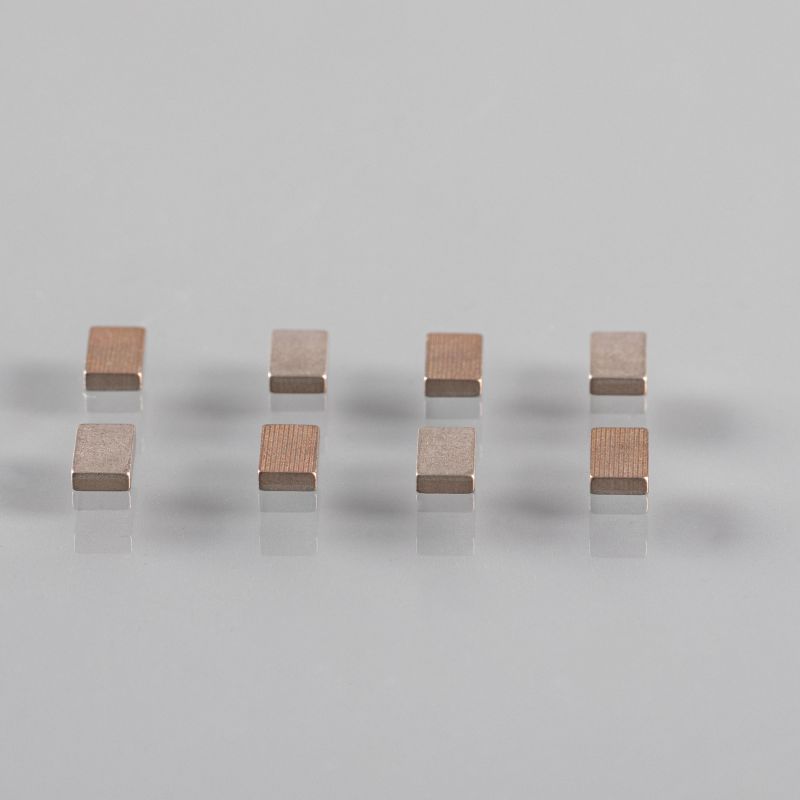

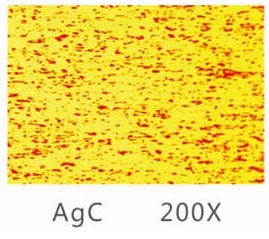

AgC

Microstructure

Tlhaloso e Akaretsang

Lisebelisoa tsa ho ikopanya tsa AgC li bonts'a khanyetso e phahameng haholo khahlano le welding ea ho ikopanya le khanyetso e tlase ea ho ikopanya.Ho hanyetsa khahlanong le welding ho eketseha ka litaba tse ntseng li eketseha tsa graphite.Lisebelisoa tsa AgC li na le boits'oaro ba ho itlotsa ha li sebelisoa e le mabitso a thellang.

Sebaka sa Kopo

E sebelisoa haholo ho li-switches tse sireletsang joalo ka li-MCB, li-MCCB, li-switch tse setseng tsa ts'ireletso, kapa li-switches tse sireletsang enjene.Kopo hangata e lumellana le AgNi, AgW, AgWC kapa Cu.

Thepa ea Lintho

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Content(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Boima ba 'mele (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Bothata ba HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Mokhoa oa tlhahiso | Sintering-Extruding | |||||

Mefuta ea Lihlahisoa

AgW

Microstructure

Tlhaloso e Akaretsang

Mabitso a entsoeng ka AgW a bontša khanyetso e phahameng ea anti-welding le khanyetso e phahameng ea khoholeho ea arc ka lebaka la sebaka se phahameng sa ho qhibiliha le boima bo phahameng ba W, hape ba na le motlakase o motle oa motlakase le oa mocheso.

Sebaka sa Kopo

Lisebelisoa tsa AgW li sebelisoa haholo ho MCCB le ACB le li-switch tse sireletsang.

Thepa ea Lintho

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Litaba tsa Ag(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Boima ba 'mele (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Bothata ba HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Mokhoa oa tlhahiso | Kenyeletso | |||||

Mefuta ea Lihlahisoa

AgWC

Microstructure

Tlhaloso e Akaretsang

Lisebelisoa tsa ho ikopanya tsa AgWC tse nang le karolo ea refractory WC li na le ho thatafala ho hoholo le ho hana ho roala ha mochini, tšekamelo e tlase ea ho hokahana le tjheseletsa, le khanyetso e tsitsitseng ea ho ikopanya le ts'ebeletso.Mabitso a AgWC a hlahisoa ke ho kenella ka phofo ea metallurgy.

Sebaka sa Kopo

Haholo-holo e sebelisoa lisebelisoa tsa ho fetola lintho tse boima, tse kang li-circuit breakers.li-circuit breakers tse setseng.Maemong a mangata li sebelisoa papaling ea asymmetric le AgC

Thepa ea Lintho

| AgWC | AgWC | AgWC | AgWC | |

| Litaba tsa Ag(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Boima ba 'mele (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Bothata ba HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Mokhoa oa tlhahiso | Kenyeletso | |||

Mefuta ea Lihlahisoa

AgWCC

Microstructure

Tlhaloso e Akaretsang

Ka lebaka la litaba tsa Ag tse phahameng, mabitso a AgWCC a na le khanyetso e tlase ea ho ikopanya.Li na le thepa e phahameng haholo ea anti-welding ka lebaka la ho ba le tungsten carbide le graphite e nang le ntlha e phahameng ea ho qhibiliha.Mabitso a AgWCC a etsoa ka ho sintering.

Sebaka sa Kopo

Haholo-holo e sebelisoa lisebelisoa tsa ho fetola lintho tse boima, tse kang li-circuit breakers.li-circuit breakers tse setseng.Maemong a mangata li sebelisoa papaling ea asymmetric le AgNi, AgW kapa AgWC.

Thepa ea Lintho

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Litaba tsa Ag(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Boima ba 'mele (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Bothata ba HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Mokhoa oa tlhahiso | Kopanya-Compacting-Sintering | |||

Mefuta ea Lihlahisoa

AgNiC

Microstructure

Tlhaloso e Akaretsang

Mabitso a AgNiC a kopanya melemo ea mabitso a AgNi le AgC.Li na le khanyetso e ntle ea khoholeho ea motlakase le thepa ea anti-welding.

Sebaka sa Kopo

Mabitso a AgNiC a sebelisoa haholo ho MCCB, ACB.

Thepa ea Lintho

| AgNiC | AgNiC | 3AgNiC | |

| Litaba tsa Ag(wt.%) | 67±1 | 73±1 | 94±1 |

| Boima ba 'mele (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Bothata ba HV | ≥50 | ≥60 | ≥30 |

| Mokhoa oa tlhahiso | Kopanya-Compacting-Sintering | ||

Mefuta ea Lihlahisoa

CuW

Microstructure

Tlhaloso e Akaretsang

Lisebelisoa tsa ho ikopanya tsa CuW li na le khanyetso e ntle khahlano le khoholeho ea arc le thepa e khahlanong le welding ho fihlela li-curret tse phahameng haholo.Mabitso a CuW a hlahisoa ka libopeho tse fapaneng tse fapaneng ka metallurgy ea phofo (ho tobetsa / sintering kapa ho kenella).Likahare tsa tungsten ke 50-80%.

Sebaka sa Kopo

Mabitso a CuW a sebelisoa haholo ho li-switchgears tse mahareng le tse phahameng.Lisebelisoa tse tloaelehileng li ho li-circuit breaker tse phahameng, li-switch switching, li-transformer switch switch le li-contact arcing tse tlase.

Ntle le moo, lisebelisoa tsa CuW li sebelisoa haholo joalo ka li-electrode, haholo-holo bakeng sa welding.

Thepa ea Lintho

| CuW | CuW | CuW | |

| Litaba tsa Cu (wt.%) | 50±2 | 40±2 | 30±2 |

| Boima ba 'mele (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Bothata ba HV | ≥115 | ≥140 | ≥175 |

| Mokhoa oa tlhahiso | Kenyeletso | ||

Mefuta ea Lihlahisoa