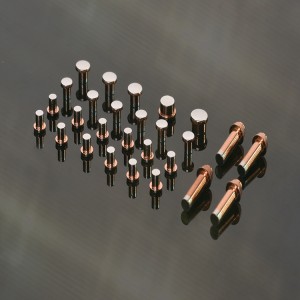

Bimetal Kopana le Rivet

Likarolo tsa Sehlahisoa

1.Double composite riveting ka katleho boloka litšepe tsa bohlokoa le ho fokotsa litšenyehelo

2.ntlafatsa ts'ebetso ea rivet riveting.

3.Sebelisa tlhahiso e tsoelang pele ea boiketsetso.

Kopo e ka Sehloohong

Lisebelisoa tsa motlakase tsa koloi, lisebelisoa tsa ntlo, litšoantšiso, khokahanyo,

Thermostat, mefuta eohle ea switch, lisebelisoa tsa sefofane, timer le lisebelisoa tsa elektroniki.

Phallo ea ts'ebetso

Ho etsa Rivet

Anealing

Ho qetela

Tlhahlobo

Ho taka

Ho paka

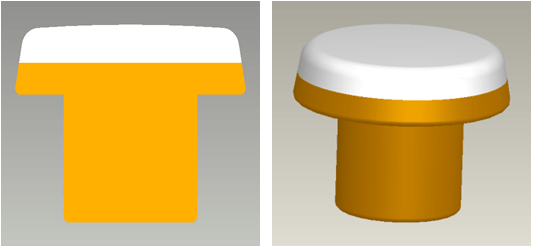

Tlhaloso ea Sehlahisoa:Ba na le ts'ebetso e ntle ea thepa e khahlanong le khoholeho ea mobu le e khahlanong le welding, 'me ba na le thepa e ntle ea ho fetisa thepa ho DC switching circuit.Mekhoa e meholo ea tlhahiso ke ts'ebetso ea ka hare ea oxidation, pre-oxidation process, metallurgy process, chemical coating process, joalo-joalo Silver Tin Oxide Bimetal Contact Rivets e na le theko e tlaase ho feta li-rivets tse tiileng.

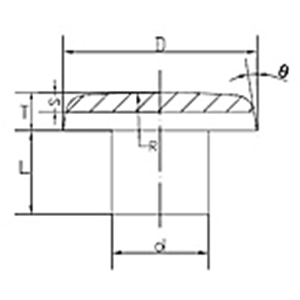

Lekanya:

| Ntho | Bophara ba hlooho D(mm) | Botenya ba hlooho T(mm) | lera bophara S(mm) | Shank bophara D(mm) | Bolelele ba Shank L(mm) | Sphere radium SR(mm) | Karolelano ea hlobo8(▫) |

| specifl-cation | 2.5 | 0.6,0.8,1.0 | 0.3–0.4 | 1.2,1.5 | 1 - 2 | 4,6 | 9 |

| 3.0 | 0.8,1.0,1.2 | 0.35 ~ 0.50 | 1.50 | 6,8 | |||

| 3.5 | 1.50,2.0 | 1 - 3 | |||||

| 4.0 | 1.0,1.2,1.5 | 2.0 | 8,10 | ||||

| 4.5 | 2.0,2.5 | ||||||

| 5.0 | 1.0,1.2,1.5,2.0 | 0.40–0.60 | 2.5 | 10,15 | |||

| 5.5 | 2.5,3.0 | ||||||

| 6.0 | 3.0 | 15,20 | |||||

| 6.5 | 1.2,1.5,2.0 | 0.50 ~ 0.70 | 3.0,3.5 | ||||

| 7.0 | 3.5 | 20,25 | |||||

| 8.0 | 4.0 | ||||||

| hlooho le shank coaxiality | ±0.1 | ±0.05 | S≤0.4+0.6 S~0.4-0.06 | -0.02,-0.1 | + 0,15 | ±0.2R | ±2 |