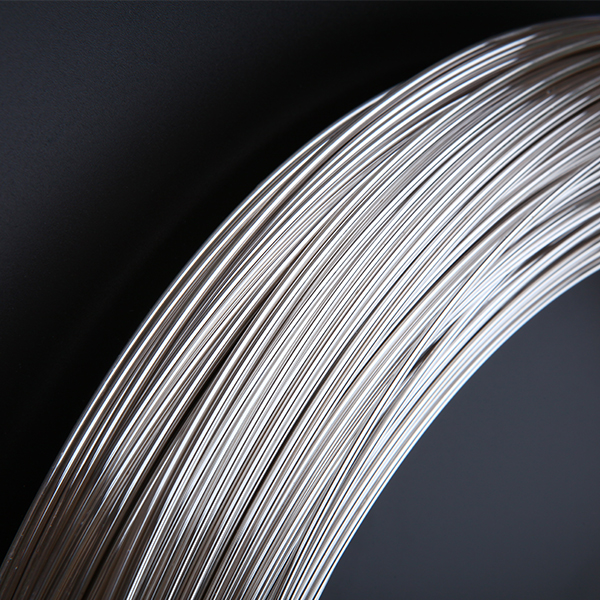

Fiilooyinka Alloy Silver

| Codsiga: |

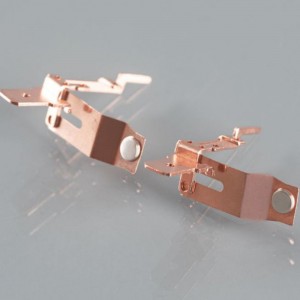

| Xidhiidhiyayaasha, wareegga wareegga, heerkulbeegyada, furayaasha caqliga leh, iwm |

| Qalabka: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Qaab-dhismeedka yar yar

2. Sharaxaada Guud

Lacagta qalinka ah iyo midhaha wanaagsan (FAg) waxay leeyihiin koronto iyo kuleyl aad u sarreeya, iska caabin xiriir hoose oo deggan, iyo karti shaqo oo wanaagsan.Waayo, iska caabin lacag ah nabaadguurka arc iyo alxanka xiriirku waa xaddidan yihiin, xoogga farsamada waa yar yahay, Sababtoo ah tirada yar ee nikkel ee lacagta miraha wanaagsan, caabbinta nabaad-guurka arc iyo xoogga farsamada ayaa ka sarreeya kan lacagta.

3. Baaxadda Codsiga

Si weyn loogu isticmaalo aaladaha hadda hooseeya, sida relays, waqti-xirayaasha, furayaasha kaaliyaha ee qalabka guriga, furayaasha kontoroolka, iwm.

4. Qalabka Agabka

| Ag | FAg | |||

| Talooyin | Fiilooyinka | Talooyin | Fiilooyinka | |

| Ag Content (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Cufnaanta (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Iska caabin (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Hardness HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Xoogga Jilitaanka (MPa) |

| 230-380 |

| 250-380 |

| Kordhinta (%) |

| 2-30 |

| 2-30 |

| Habka wax-soo-saarka | Dul-qaadid | Extruding -Sawir | Dul-qaadid | Extruding -Sawir |

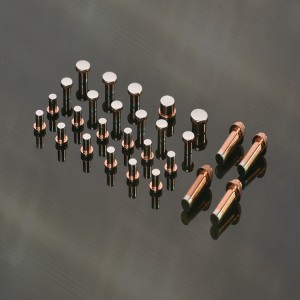

5. Noocyada Alaabta

AgNi

1. Qaab-dhismeedka yar yar

2. Sharaxaada Guud

Agabka AgNi waxay leeyihiin iska caabin sare oo u adkaysta nabaad guurka iyo alxanka xidhiidhka marka loo eego Ag ama FAg.Labada hantiba waxaa lagu wanaajiyey iyadoo la kordhinayo nuxurka Ni.Dhammaan agabyada AgNi waxay muujinayaan karti-shaqayn wanaagsan oo ay fududahay in la alxan karo si loola xidhiidho taageerooyinka.U janjeerta hoose ee wareejinta alaabta ee codsiyada DC.Agabka AgNi waa agab deegaan-ilaaliye.

3. Baaxadda Codsiga

Agabka xiriirka AgNi waxay ka helaan codsiyo kala duwan oo kala duwan oo ku jira aaladaha beddelka tamarta hooseeya.Waxaa loo isticmaalaa soo-gudbinta, xiriiriyeyaasha yaryar, furayaasha nalka, kontaroolayaasha heerkulka iyo sidoo kale furayaasha ilaalinta (waxaa loo adeegsadaa lammaane xiriir aan asymmetrical ahayn, tusaale ahaan, lidka ku ah agabkaAgC, AgZnO amaAgSnO2).

4. Qalabka Agabka

| Fiilooyinka | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ni Content (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Cufnaanta (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Koronto-iska-caabbinta (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Hardness HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Xoogga Jilitaanka (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Dheeraynta(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Habka wax-soo-saarka | Sintering-Extruding | |||||

5. Noocyada Alaabta

AgCdO

1. Qaab-dhismeedka yar yar

2. Sharaxaada Guud

Xiriirada AgCdO waxay ka tirsan yihiin kooxda kuwa aadka loo isticmaalo ee ku saabsan qalabka korantada ee hooseeya.Waxay isku daraan iska caabin lagu qanco oo ka dhan ah alxanka xiriirka leh caabbinta nabaad-guurka ee wanaagsan iyo iska caabin xiriir hooseeya oo dhammaystiran nolosha adeeggeeda.Waxaa lagu soo saaraa laba farsamooyin oo kala duwan, pre-oxidation-sintering-extruding iyo oxidation gudaha.Labada xaaladoodba waxa ku jira Cd0 waxay u dhaxayn kartaa 10 ilaa 20wt. Si kastaba ha ahaatee, Cd iyo Cd0 waxa loo arkaa inay khatar ku yihiin caafimaadka iyo deegaanka.Sababtan awgeed isticmaalka agabka AgCdO waa laga mamnuuci doonaa wadamo badan.

3. Baaxadda Codsiga

Inta badan loo isticmaalo ku dhawaad nooc kasta oo ah qalabka beddelka danab yar.Caadi ahaan waxaa loo adeegsadaa mikroswitches-ka, relays-ka, furayaasha nalka, xiriiriyeyaasha, furayaasha qalabka guriga, qaar ka mid ah furayaasha ilaalinta, iyo sidoo kale noocyo kala duwan oo wareegyada wareegga ah.

4. Qalabka Agabka

| Fiilooyinka | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| Waxyaabaha ay ka kooban tahay CdO(wt.%) | 10±1 | 13.5 ± 1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Cufnaanta (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Koronto iska caabin ah (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Hardness HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Xoogga Jilitaanka (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Dheeraynta(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Habka wax-soo-saarka | Pre-oxidation-Sintering-Extruding | Oxidaynta Gudaha | |||||

5. Noocyada Alaabta

AgZnO

1. Qaab-dhismeedka yar yar

2. Sharaxaada Guud

Iska caabin sare oo ka soo horjeeda alxanka xiriirka ayaa tilmaamaya agabyada AgZnO.Waxay sidoo kale muujinayaan iska caabin wanaagsan oo ka dhan ah nabaad-guurka arc.Iska caabbinta xiriirka AgZnO waxay u egtahay inay ka sarreyso kan AgCd0.AgZnO waxaa lagu soo saari karaa iyada oo la adeegsanayo pre-oxidation-sintering - soo saarista, farsamooyinka isku-dhafka-isku-dhafka ah iyo sidoo kale oksaydhka gudaha.Agabka AgZnO waa bey'ad -qalabka ilaalinta

3. Baaxadda Codsiga

Inta badan waxaa loo isticmaalaa dabaylaha wareegga, gaar ahaan kuwa caalamiga ah.Qaybaha kale ee codsiga waa furayaasha ilaalinta matoorka, jebiyayaasha wareegga hadda jira iyo wareejinta AC.

4. Qalabka Agabka

| Fiilooyinka | AgZnO | AgZnO |

| Tusmada ZnO(wt.%) | 8±1 | 10±1 |

| Cufnaanta (g/cm3) | .9.65 | 9.60 |

| Koronto iska caabinta (NO•cm) | 2.25 | 2.35 |

| Hardness HV | E30 | 85 |

| Xoogga Jilitaanka (MPa) | 285-350 | 285-350 |

| Dheeraynta(%) | 15-25 | 12-20 |

| Habka wax-soo-saarka | Pre-oxidation -Sintering-Extruding | |

5. Noocyada Alaabta

AgSnO2

1. Qaab-dhismeedka yar yar

2. Sharaxaada Guud

AgSnO2/AgSn021n203 waa agab xidhiidhka korantada ku habboon.Waxay leeyihiin bandhigyo wanaagsan oo ka hortagga nabaad-guurka iyo guryaha alxanka, waxayna leeyihiin hanti wareejinta agabka wanaagsan ee wareegga beddelka DC.Habka ugu muhiimsan ee wax soo saarka waa habka oksaydhka gudaha, habka pre-oxidation, habka birta budada, habka daahan kiimikada, iwm.

3. Baaxadda Codsiga

Si ballaaran loo isticmaalo noocyada kala duwan ee contactors , relays, wareegyada iyo furayaasha, iwm.

4. Qalabka Agabka

AgSnO2

| Fiilooyinka | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Waxyaabaha SnO2 (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Cufnaanta (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Iska caabin (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Xoogga Jilitaanka (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Dheeraynta(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Habka wax-soo-saarka | Pre-oxidation-Sintering-Extruding | Dahaarka Kiimikada | Isku-dhafka-Sintering-Extruding | ||

AgSnO2In203

| Fiilooyinka | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Content (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Cufnaanta (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Iska caabin (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Hardness HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Xoogga Jilitaanka (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Dheeraynta(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Habka wax-soo-saarka | Pre-oxidation-Sintering-Extruding | Oxidaynta Gudaha | |||

5. Noocyada Alaabta

AgSnO2In2O3

1. Sharaxaada Guud

2. Qaab-dhismeedka yar yar

AgSnO2lAgSn021n203 waa agab xidhiidhka korantada ku habboon deegaanka.Waxay leeyihiin bandhigyo wanaagsan oo ka hortagga nabaad-guurka iyo guryaha alxanka, waxayna leeyihiin hanti wareejinta agabka wanaagsan ee wareegga beddelka DC.Habka ugu muhiimsan ee wax soo saarka waa habka oksaydhka gudaha, habka hore ee oksaydhka, habka birta budada ah, habka daahan kiimikada, iwm.

3. Baaxadda Codsiga

Si ballaaran loo isticmaalo noocyada kala duwan ee contactors , relays, wareegyada iyo furayaasha, iwm.

4. Qalabka Agabka

AgSnO2

| Fiilooyinka | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Waxyaabaha SnO2 (wt.%) | 10 ± 1 | 10 ± 1 | 12±1 | 12±1 | 15 ± 1 |

| Cufnaanta (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Iska caabin (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Xoogga Jilitaanka (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Dheeraynta(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Habka wax-soo-saarka | Pre-oxidation-Sintering-Extruding | Dahaarka Kiimikada | Isku-dhafka-Sintering-Extruding | ||

AgSnO2In203

| Fiilooyinka | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Content (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Cufnaanta (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Iska caabin (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Hardness HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Xoogga Jilitaanka (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Dheeraynta(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Habka wax-soo-saarka | Pre-oxidation-Sintering-Extruding | Oxidaynta Gudaha | |||