XIRIIRKA BIRTA BUDODA

| Codsiga: |

| Xidhiidhiyayaasha, wareegga wareegga, heerkulbeegyada, furayaasha caqliga leh, iwm |

| Qalabka: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

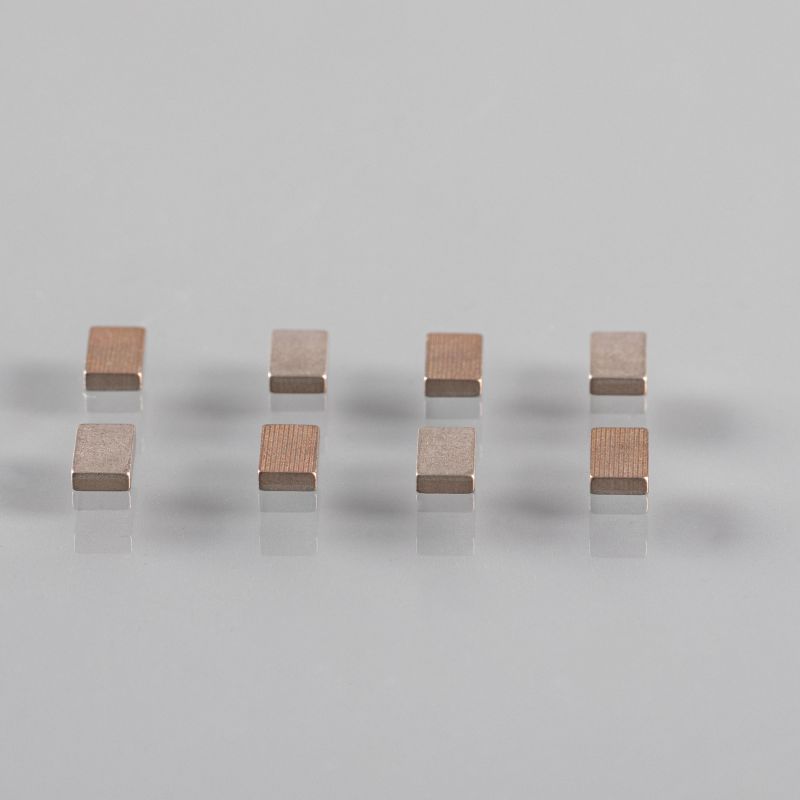

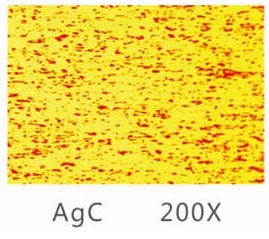

AgC

Qaab-dhismeedka yar yar

Sharaxaada Guud

Qalabka xiriirka AgC ayaa muujinaya iska caabin aad u sarreeya oo ka soo horjeeda alxanka xiriirka iyo iska caabbinta xiriirka hoose.Iska caabinta alxanka waxay kordhisaa maadada garaafka ee sii kordhaysa.Agabka AgC waxay leeyihiin dabeecad is-saliimayn marka loo isticmaalo sidii xidhiidho simbiriirixan leh.

Baaxadda Codsiga

Inta badan loo isticmaalo furayaasha ilaalinta sida MCB-yada, MCCB-yada, furayaasha ilaalinta hadda hadhsan, ama furayaasha ilaalinta matoorka.Codsigu waxa uu caadi ahaan ku siman yahay AgNi,AgW, AgWC ama Cu.

Guryaha Alaabta

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C waxa ku jira(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Cufnaanta (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Koronto iska caabin ah (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Hardness HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Habka wax-soo-saarka | Sintering-Extruding | |||||

Noocyada Alaabta

AgW

Qaab-dhismeedka yar yar

Sharaxaada Guud

Xidhiidhada laga sameeyay AgW waxay muujinayaan iska caabin sare oo alxanka ka soo horjeeda iyo caabbinta sare ee nabaadguurka arc sababtoo ah barta dhalaalka sare iyo adkaanta sare ee W, waxay sidoo kale leeyihiin koronto iyo kulayl wanaagsan.

Baaxadda Codsiga

Agabka AgW waxaa inta badan loo isticmaalaa danab hooseeya MCCB iyo ACB iyo furayaasha ilaalinta.

Guryaha Alaabta

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag Content(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Cufnaanta (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec. Iska caabin (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Hardness HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Habka wax-soo-saarka | Soo galitaanka | |||||

Noocyada Alaabta

AgWC

Qaab-dhismeedka yar yar

Sharaxaada Guud

Agabka xidhiidhka AgWC ee ka kooban qaybta refractory WC waxay leeyihiin adayg sare iyo iska caabin ah xidhashada makaanik, u janjeera hoose ee alxanka xidhiidhka, iyo xidhiidh xasilloon oo iska caabin ah ee adeegga.Xiriirada AgWC waxaa soo saara birta birta ah ee budada ah.

Baaxadda Codsiga

Inta badan waxaa loo adeegsadaa aaladaha beddelka shaqada culus, sida kuwa wareegga wareegga.Haraaga wareegga wareegga hadda jira.Xaalado badan ayaa loo adeegsadaa ciyaarta asymmetric ee AgC

Guryaha Alaabta

| AgWC | AgWC | AgWC | AgWC | |

| Ag Content(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Cufnaanta (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Koronto iska caabin ah (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Hardness HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Habka wax-soo-saarka | Soo galitaanka | |||

Noocyada Alaabta

AgWCC

Qaab-dhismeedka yar yar

Sharaxaada Guud

Sababtoo ah maaddada sare ee Ag, xiriirada AgWCC waxay leeyihiin iska caabin xiriir hoose.Waxay leeyihiin sifooyin alxanka ka-hortagga oo aad u sarreeya sababtoo ah ka kooban tungsten carbide iyo graphite oo leh barta dhalaalaysa sare.Xidhiidhada AgWCC waxaa lagu soo saaray sintering.

Baaxadda Codsiga

Inta badan waxaa loo adeegsadaa aaladaha beddelka shaqada culus, sida kuwa wareegga wareegga.Haraaga wareegga wareegga hadda jira.Xaalado badan ayaa loo istcimaalay kulan asymmetric ah oo lala yeesho AgNi, AgW ama AgWC.

Guryaha Alaabta

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag Content(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Cufnaanta (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Hardness HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Habka wax-soo-saarka | Isku-dhafka-Isku-dhafka-Sintering | |||

Noocyada Alaabta

AgNiC

Qaab-dhismeedka yar yar

Sharaxaada Guud

Xiriirada AgNiC waxay isku daraan faa'iidooyinka xiriirka AgNi iyo AgC.Waxay leeyihiin iska caabin wanaagsan oo ay u leeyihiin nabaad-guurka korantada iyo guryaha alxanka.

Baaxadda Codsiga

Xiriirada AgNiC waxaa inta badan lagu isticmaalaa MCCB, ACB.

Guryaha Alaabta

| AgNiC | AgNiC | 3AgNiC | |

| Ag Content(wt.%) | 67±1 | 73±1 | 94±1 |

| Cufnaanta (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Koronto iska caabin ah (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Hardness HV | ≥50 | ≥60 | ≥30 |

| Habka wax-soo-saarka | Isku-dhafka-Isku-dhafka-Sintering | ||

Noocyada Alaabta

CuW

Qaab-dhismeedka yar yar

Sharaxaada Guud

Qalabka xidhiidhka ee CuW waxay leeyihiin iska caabin heersare ah oo ka dhan ah nabaadguurka arc iyo kuwa alxanka ka hortagga ilaa curret aad u sarreeya.Xidhiidhada CuW waxa lagu soo saaraa qaabab kala duwan oo aad u kala duwan iyada oo la adeegsanayo biraha budada ah (cadaadis / shaandheyn ama dhexgelin).Waxyaabaha tungstenku waa 50%-80%.

Baaxadda Codsiga

Xidhiidhada CuW waxaa inta badan loo adeegsadaa qalabka beddelaadda tamarta dhexe iyo kuwa sare.Codsiyada caadiga ah waa kuwa ku jira koronto-dhaliyaha sare ee wareegga wareegga, furayaasha rarka, beddelka beddelayaasha tuubada beddelayaasha iyo xiriiriyeyaasha korantada hooseeya.

Intaa waxaa dheer, qalabka CuW waxaa si ballaaran loo isticmaalaa sida electrodes, ugu horrayn alxanka.

Guryaha Alaabta

| CuW | CuW | CuW | |

| Cutubka (wt.%) | 50±2 | 40±2 | 30±2 |

| Cufnaanta (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec. Iska caabin (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Hardness HV | ≥115 | ≥140 | ≥175 |

| Habka wax-soo-saarka | Soo galitaanka | ||

Noocyada Alaabta