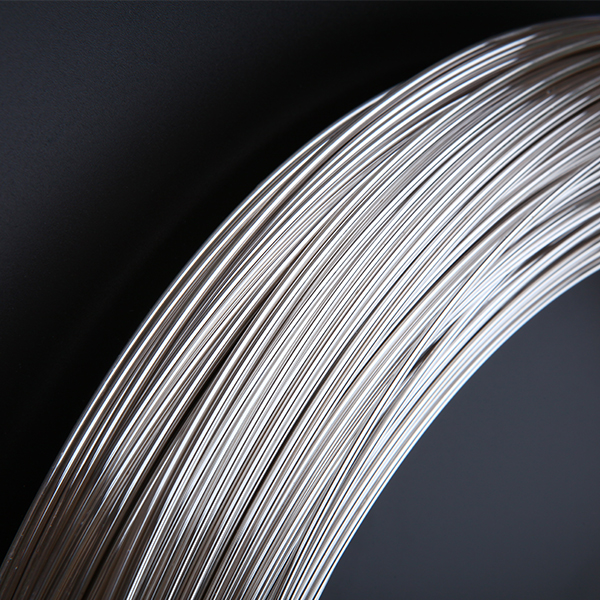

Silver Alloy Wires

| Application: |

| Macontactor, macircuit breaker, thermostats, akangwara switch, nezvimwe |

| The Material: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Microstructure

2. Tsanangudzo Yese

Sirivha uye yakanakisa zviyo sirivha (FAg) ine yakakwira zvakanyanya magetsi uye inopisa conductivity, yakaderera uye yakagadzikana yekubata kuramba, uye kushanda zvakanaka.Kuti sirivha inopokana nearc erosion uye contact welding ishoma, simba remagetsi rakaderera, Nekuda kwehuwandu hudiki hwenickel mufinere tsanga sirivheri, kuramba kukukurwa kwearc uye kusimba kwemagetsi kwakakwira kupfuura iyo yesirivha.

3. Chikumbiro cheKushandisa

Inoshandiswa zvakanyanya mumidziyo yakaderera yazvino, senge relay, nguva, ebetsero switch yemidziyo yemumba, control switch, nezvimwe.

4. Zvinhu Zvokuita

| Ag | FAg | |||

| Mazano | Waya | Mazano | Waya | |

| Ag Zvirimo (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Density (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Resistivity (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Kuoma kweHV | ≥40 | ≥60 | ≥45 | ≥65 |

| Tensile Simba (MPa) |

| 230-380 |

| 250-380 |

| Elongation (%) |

| 2-30 |

| 2-30 |

| Manufacturing process | Extruding-Rolling | Extruding -Drawing | Extruding-Rolling | Extruding -Drawing |

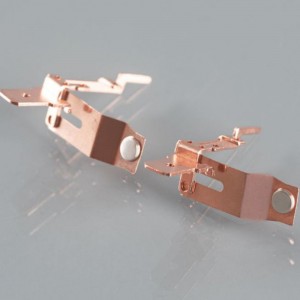

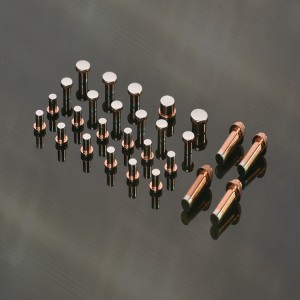

5. Product Types

AgNi

1. Microstructure

2. Tsanangudzo Yese

Zvishandiso zveAgNi zvine kukwirira kwekukukurwa kwearc uye kubata welding pane Ag kana FAg.Zvese zviri zviviri zvivakwa zvinovandudzwa nekuwedzera Ni yemukati.Zvese zveAgNi zvinhu zvinoratidza kushanda zvakanaka uye zviri nyore kuti weld kubata zvitsigiro.Yakaderera maitiro ekutamisa zvinhu muDC application.AgNi zvinhu zvinhu zvinodzivirira zvakatipoteredza.

3. Chikumbiro cheKushandisa

Zvishandiso zveAgNi zvinowana kuwanda kwekushandisa mune yakaderera voltage switching zvishandiso.Iwo anoshandiswa mune relay, madiki macontactor, mwenje switch, tembiricha controller pamwe neanodzivirira switch (anoshandiswa mune asymmetric contact pairs, semuenzaniso, againstAgC, AgZnO kanaAgSnO2 zvinhu).

4. Zvinhu Zvokuita

| Waya | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ni Content (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Density (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Kuoma kweHV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Tensile Simba (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Elongation(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Manufacturing process | Sintering-Extruding | |||||

5. Product Types

AgCdO

1. Microstructure

2. Tsanangudzo Yese

AgCdO anobatika ndeweboka reanonyanya kushandiswa pamunda weyakaderera voltage emagetsi emagetsi.Ivo vanosanganisa kurwisa kunogutsa kupesana nekubata welding ine yakanaka arc erosion kuramba uye yakaderera yakaderera yekubata kuramba pamusoro pehupenyu hwayo hwesevhisi.Izvo zvinogadzirwa nemaitiro maviri akasiyana, pre-oxidation-sintering-extruding uye mukati oxidation.Muzviitiko zvose zviri zviviri zveCd0 zvinogona kubva pa10 kusvika pa20wt..Zvisinei, Cd neCd0 zvinoonekwa seine njodzi kuutano nenharaunda.Nechikonzero ichi kushandiswa kwezvinhu zveAgCdO kucharambidzwa munyika dzakawanda.

3. Chikumbiro cheKushandisa

Inonyanya kushandiswa munenge marudzi ese epasi voltage switching madivayiri.Iwo anowanzo shandiswa mumamicroswitches, relays, mwenje switch, macontactor, switch yemidziyo yemumba, mamwe marudzi emagetsi ekudzivirira, pamwe nemamwe marudzi emagetsi emagetsi.

4. Zvinhu Zvokuita

| Waya | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| CdO Zvirimo(wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Density (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Kuoma kweHV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Tensile Simba (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Elongation(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||||

5. Product Types

AgZnO

1. Microstructure

2. Tsanangudzo Yese

Kupokana kwakanyanya kunopesana nekubata welding kunoratidza AgZnO zvinhu.Vanoratidzawo kumira kwakanaka kurwisa arc erosion.Kubata kuramba kweAgZnO kunowanzo kuve kwakakwira kupfuura iyo yeAgCd0.AgZnO inogona kugadzirwa nenzira yepre-oxidation-sintering — extruding, mixing-compacting-sintering techniques pamwe chete neoxidation yemukati.Zvishandiso zveAgZnO nharaunda-yekudzivirira zvinhu.

3. Chikumbiro cheKushandisa

Inonyanya kushandiswa mumasekete breakers, kunyanya mune universal circuit breakers.Mimwe minda yekushandiswa imotor inodzivirira switch, yasara yazvino yedunhu mabreaker uye AC relay.

4. Zvinhu Zvokuita

| Waya | AgZnO | AgZnO |

| ZnO Content(wt.%) | 8±1 | 10±1 |

| Density (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Kuoma kweHV | E30 | 85 |

| Tensile Simba (MPa) | 285-350 | 285-350 |

| Elongation(%) | 15-25 | 12-20 |

| Manufacturing process | Pre-oxidation -Sintering-Extruding | |

5. Product Types

AgSnO2

1. Microstructure

2. Tsanangudzo Yese

AgSnO2/AgSn021n203 ndeye eco-hushamwari magetsi ekubata zvinhu.Vane maitiro akanaka mu-anti-erosion uye anti-welding properties, uye vane yakanaka anti-material kutamisa pfuma muDC switching circuit.Iwo makuru ekugadzira maitiro ndeyemukati oxidation process, pre-oxidation process, poda metallurgy process, makemikari coating process, nezvimwe..

3. Chikumbiro cheKushandisa

Inoshandiswa zvakanyanya mumhando dzakasiyana dzemacontactor, relays, circuit breakers uye switch, nezvimwe.

4. Zvinhu Zvokuita

AgSnO2

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Zvirimo (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Density (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistivity (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Kuoma kweHV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile Simba (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Chemical Coating | Kusanganisa-Sintering-Extruding | ||

AgSnO2In203

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Zvirimo (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Density (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kuramba (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Kuoma kweHV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile Simba (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||

5. Product Types

AgSnO2In2O3

1. Tsanangudzo Yese

2. Microstructure

AgSnO2lAgSn021n203 ndeye eco-hushamwari magetsi ekubata zvinhu.Vane maitiro akanaka mu-anti-erosion uye anti-welding properties, uye vane yakanaka anti-material kutamisa pfuma muDC switching circuit.Iwo makuru ekugadzira maitiro ndeyemukati oxidation process, pre-oxidation process, poda metallurgy process, makemikari coating process, nezvimwe.

3. Chikumbiro cheKushandisa

Inoshandiswa zvakanyanya mumhando dzakasiyana dzemacontactor, relays, circuit breakers uye switch, nezvimwe.

4. Zvinhu Zvokuita

AgSnO2

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Zvirimo (wt.%) | 10 ±1 | 10 ±1 | 12±1 | 12±1 | 15 ±1 |

| Density (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Kuramba (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Kuoma kweHV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile Simba (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Chemical Coating | Kusanganisa-Sintering-Extruding | ||

AgSnO2In203

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Zvirimo (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Density (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kuramba (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Kuoma kweHV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile Simba (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||