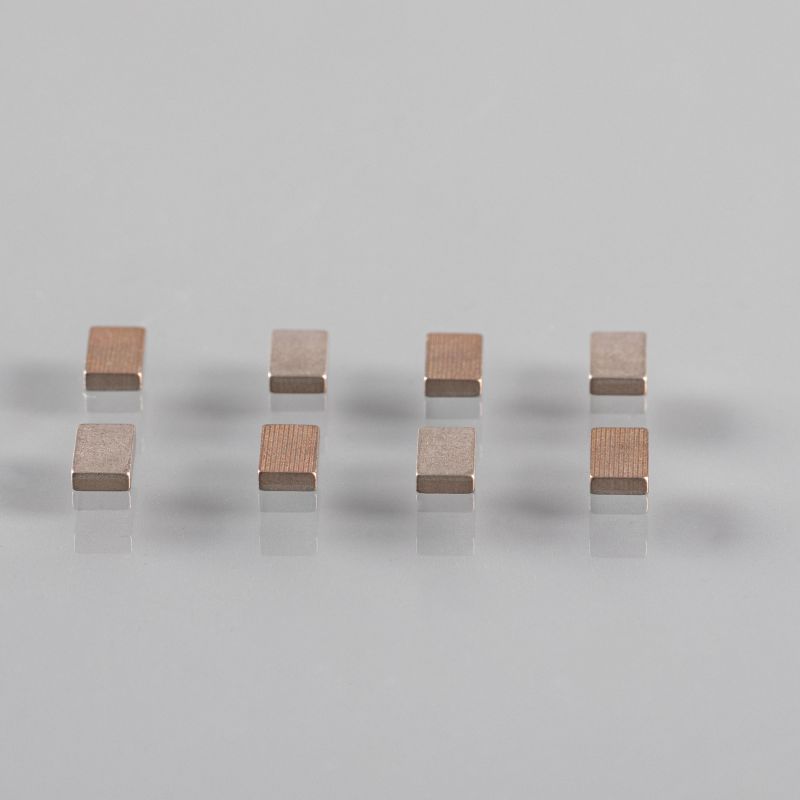

POWDER METAL CONTACTS

| Application: |

| Macontactor, macircuit breaker, thermostats, akangwara switch, nezvimwe |

| The Material: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

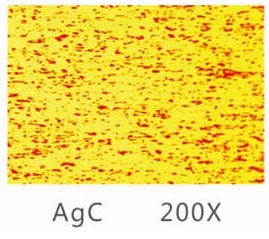

AgC

Microstructure

General Description

AgC yekubata zvinhu inoratidza yakanyanya kupikisa kupesana nekubata welding uye yakaderera yekubata kuramba.Kupokana newelding kunowedzera nekuwedzera graphite zvemukati.Zvishandiso zveAgC zvine hunhu hwekuzvizora kana uchishandiswa sevanotsvedza.

Application Scope

Inonyanya kushandiswa mukudzivirira switch senge MCBs, MCCBs, yasara ikozvino yekudzivirira switch, kana mota inodzivirira switch.Chishandiso chinowanzo muasymmetric match neAgNi, AgW, AgWC kana Cu.

Material Properties

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Zvemukati(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Density (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Kuoma kweHV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Manufacturing process | Sintering-Extruding | |||||

Product Types

AgW

Microstructure

General Description

Mazita akagadzirwa neAgW anoratidza yakakwira anti-welding kuramba uye yakanyanya kuramba kukukurwa kwearc nekuda kwekunyanya kunyungudika uye kuomarara kweW, ivo zvakare vane yakanaka magetsi uye yekupisa conductivity.

Application Scope

AgW zvinhu zvinonyanya kushandiswa mune yakaderera voltage MCCB uye ACB uye ekudzivirira switch.

Material Properties

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag Zvirimo(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Density (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Kuoma kweHV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Manufacturing process | Kupinza | |||||

Product Types

AgWC

Microstructure

General Description

Iyo AgWC yekubata zvinhu zvine iyo refractory chikamu WC ine kuomarara kwakanyanya uye kuramba kune mechaniki kupfeka, tsika yakaderera yekubata welding, uye yakagadzikana yekubata kuramba musevhisi.AgWC maitirwo anogadzirwa nehupfu metallurgy infiltration.

Application Scope

Inonyanya kushandiswa mune zvinorema-basa switching madivayiri, akadai sedunhu mabreak.zvakasara zvazvino zvemadunhurirwa.Muzviitiko zvakawanda ivo vanoshandiswa mune asymmetric match neAgC

Material Properties

| AgWC | AgWC | AgWC | AgWC | |

| Ag Zvirimo(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Density (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Kuoma kweHV | ≥100 | ≥125 | ≥135 | ≥155 |

| Manufacturing process | Kupinza | |||

Product Types

AgWCC

Microstructure

General Description

Nekuda kweiyo Ag yemukati, maAgWCC ekubatika ane yakaderera kuonana kuramba.Ivo vane yakakwirira kwazvo anti-welding zvivakwa nekuda kweine tungsten carbide uye graphite ine yakakwira kunyungudika.AgWCC mabatirwo anogadzirwa ne sintering.

Application Scope

Inonyanya kushandiswa mune zvinorema-basa switching madivayiri, akadai sedunhu mabreak.zvakasara zvazvino zvemadunhurirwa.Muzviitiko zvakawanda anoshandiswa mumutambo weasymmetric neAgNi, AgW kana AgWC.

Material Properties

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag Zvirimo(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Density (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Kuoma kweHV | ≥50 | ≥80 | ≥60 | ≥75 |

| Manufacturing process | Mixing-Compacting-Sintering | |||

Product Types

AgNiC

Microstructure

General Description

AgNiC vanobatika vanosanganisa zvakanakira zveAgNi uye AgC vanobatika.Vane kupikisa kwakanaka kukukurwa kwemagetsi uye anti-welding properties.

Application Scope

AgNiC contacts anonyanya kushandiswa muMCCB, ACB.

Material Properties

| AgNiC | AgNiC | 3AgNiC | |

| Ag Zvirimo(wt.%) | 67±1 | 73±1 | 94±1 |

| Density (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Kuoma kweHV | ≥50 | ≥60 | ≥30 |

| Manufacturing process | Mixing-Compacting-Sintering | ||

Product Types

CuW

Microstructure

General Description

CuW yekubata zvinhu zvine yakanakisa kupikisa kurwisa arc erosion uye anti-welding zvivakwa kusvika kune yakakwira curret.CuW yekubata inogadzirwa mumhando dzakasiyana siyana kuburikidza nehupfu simbi (kudzvanya / sintering kana kupinza).Iyo tungsten yemukati ndeye 50% -80%.

Application Scope

CuW contacts dzinonyanya kushandiswa mukati uye yakakwira voltage switchgears.Mashandisirwo akajairika ari mumagetsi emagetsi emagetsi akakwira, ma switch switch, transformer switch tap inochinja uye yakaderera voltage arcing contacts.

Pamusoro pezvo, CuW zvinhu zvinoshandiswa zvakanyanya sema electrode, kunyanya kune welding.

Material Properties

| CuW | CuW | CuW | |

| Cu Content (wt.%) | 50±2 | 40±2 | 30±2 |

| Density (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Kuoma kweHV | ≥115 | ≥140 | ≥175 |

| Manufacturing process | Kupinza | ||

Product Types