OEM/ODM Factory Brass Electrical Contact – POWDER METAL CONTACTS – ZHJ

China OEM/ODM Factory Brass Electrical Contact - POWDER METAL CONTACTS - ZHJ Manufacturer and Supplier | ZHJ Detail:

| Application: |

| Contactors, circuit breakers, thermostats, intelligent switches, etc |

| The Material: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

Microstructure

General Description

AgC contact materials show a very high resistance against contact welding and low contact resistance. Resistance against welding increases with increasing graphite content. AgC materials have self-lubricating behavior when used as sliding contacts.

Application Scope

Mainly used in protective switches such as MCBs, MCCBs, residual current protective switches, or motor protective switches. Application is normally in asymmetric match with AgNi,AgW, AgWC or Cu.

Material Properties

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Content(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Density (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Hardness HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Manufacturing process |

Sintering-Extruding |

|||||

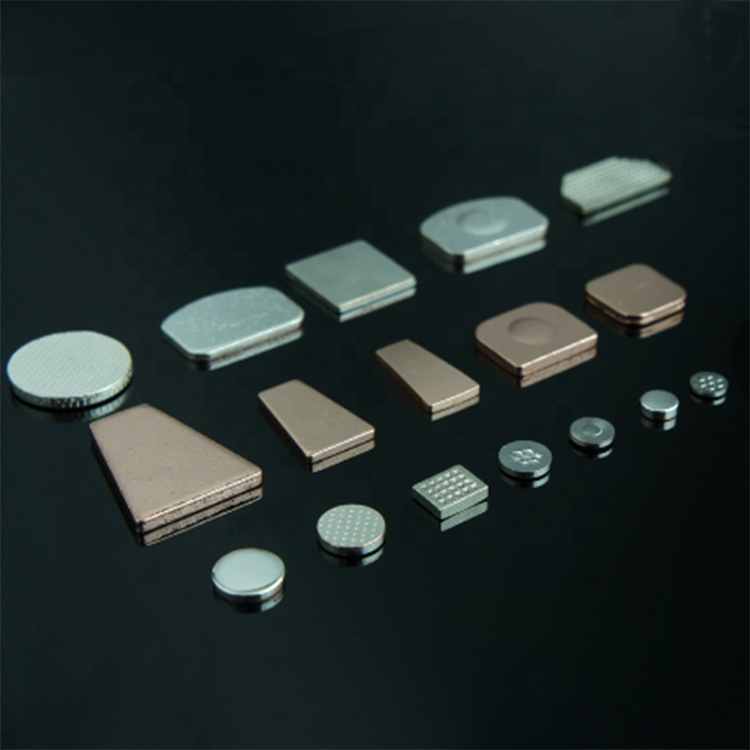

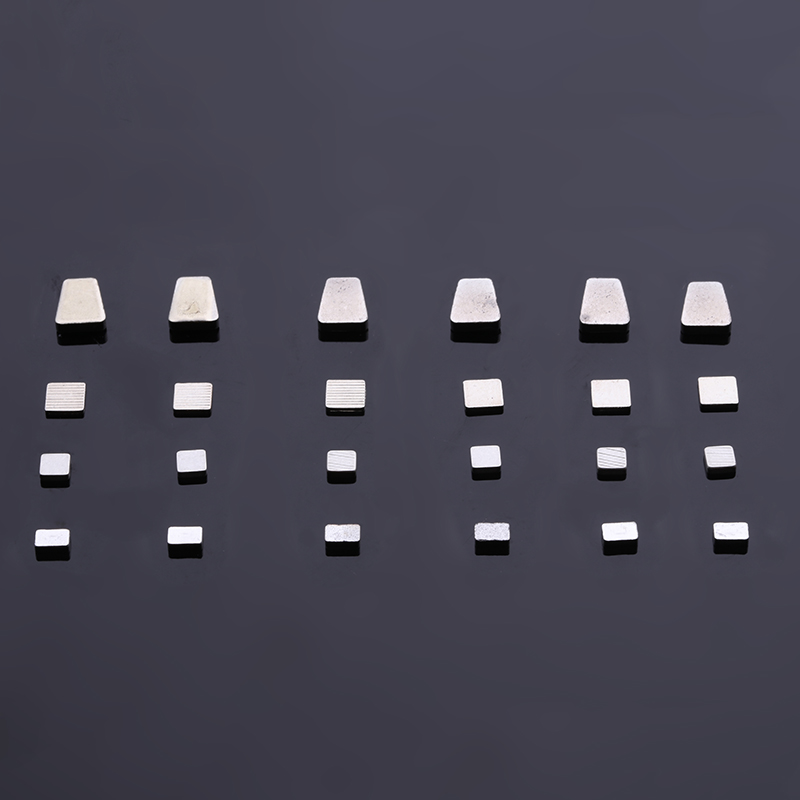

Product Types

Microstructure

General Description

Contacts made of AgW show a high anti-welding resistance and a high resistance to arc erosion due to high melting point and high hardness of W, they also have a good electrical and thermal conductivity.

Application Scope

AgW materials are mainly used in low voltage MCCB and ACB and protective switches.

Material Properties

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag Content(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Density (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Hardness HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Manufacturing process | Infiltration | |||||

Product Types

Microstructure

General Description

The AgWC contact materials containing the refractory component WC have high hardness and resistance to mechanical wear, a low tendency towards contact welding, and a relatively stable contact resistance in service. AgWC contacts are produced by powder metallurgy infiltration.

Application Scope

Mainly used in heavy-duty switching devices, such as circuit breakers. residual current circuit breakers. In many cases they are used in asymmetric match with AgC

Material Properties

| AgWC | AgWC | AgWC | AgWC | |

| Ag Content(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Density (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Hardness HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Manufacturing process | Infiltration | |||

Product Types

Microstructure

General Description

Due to high Ag content , AgWCC contacts have low contact resistance. They have very high anti-welding properties due to containing tungsten carbide and graphite with high melting point. AgWCC contacts are manufactured by sintering.

Application Scope

Mainly used in heavy-duty switching devices, such as circuit breakers. residual current circuit breakers. In many cases they are used in asymmetric match with AgNi, AgW or AgWC.

Material Properties

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag Content(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Density (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Hardness HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Manufacturing process | Mixing-Compacting-Sintering | |||

Product Types

Microstructure

General Description

AgNiC contacts combine the advantages ofAgNi and AgC contacts. They have good resistance to electrical erosion and anti-welding properties.

Application Scope

AgNiC contacts are mainly used in MCCB, ACB.

Material Properties

| AgNiC | AgNiC | 3AgNiC | |

| Ag Content(wt.%) | 67±1 | 73±1 | 94±1 |

| Density (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Hardness HV | ≥50 | ≥60 | ≥30 |

| Manufacturing process | Mixing-Compacting-Sintering | ||

Product Types

Microstructure

General Description

CuW contact materials have excellent resistsnce against arc erosion and anti-welding properties up to very high curret. CuW contacts are produced in a great variety of shapes by means of powder metallurgy (pressing / sintering or infiltration). The tungsten content is 50%-80%.

Application Scope

CuW contacts are mainly used in medium and high voltage switchgears. Typical applications are in high voltage circuit breakers, load switches, transformer switches tap changers and low voltage arcing contacts.

In addition, CuW materials are widely used as electrodes, primarily for welding.

Material Properties

| CuW | CuW | CuW | |

| Cu Content (wt.%) | 50±2 | 40±2 | 30±2 |

| Density (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Hardness HV | ≥115 | ≥140 | ≥175 |

| Manufacturing process | Infiltration | ||

Product Types

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for China OEM/ODM Factory Brass Electrical Contact - POWDER METAL CONTACTS - ZHJ Manufacturer and Supplier | ZHJ , The product will supply to all over the world, such as: Pakistan , United Arab Emirates , Venezuela , Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.