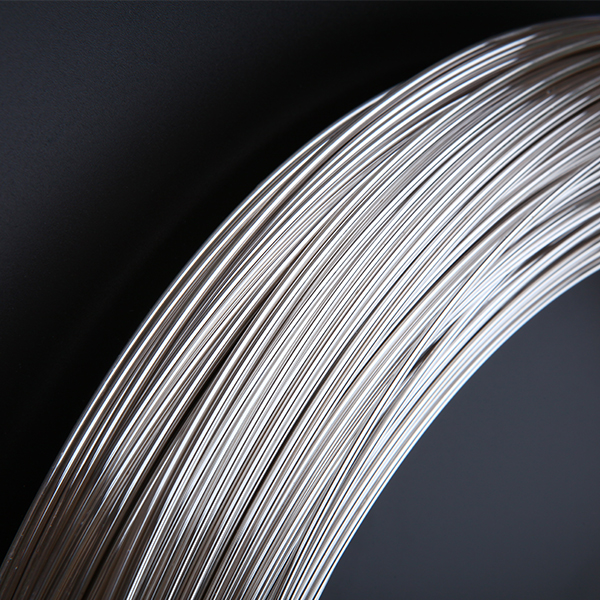

Mawaya a Silver Alloy

| Ntchito: |

| Ma contactor, ma circuit breakers, thermostats, ma switch anzeru, etc |

| Zofunika: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAG

1. Microstructure

2. Kufotokozera Zazikulu

Silver and fine grain silver (FAg) ali ndi magetsi okwera kwambiri komanso matenthedwe, kukana kutsika komanso kukhazikika, komanso kugwira ntchito bwino.Pakuti siliva kukana kukokoloka kwa arc ndi kukhudzana kuwotcherera ndizochepa, mphamvu zamakina ndizochepa, Chifukwa cha kuchuluka kwa faifi tambala mu siliva wabwino wambewu, kukana kukokoloka kwa arc ndi mphamvu zamakina ndizokwera kuposa zasiliva.

3. Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri pazida zotsika, monga ma relay, zowerengera nthawi, zosinthira zothandizira zida zapakhomo, zosinthira zowongolera, ndi zina zambiri.

4. Zinthu Zakuthupi

| Ag | FAG | |||

| Malangizo | Mawaya | Malangizo | Mawaya | |

| Za Ag (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Kuchulukana (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Kukaniza (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Kulimba kwa HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Mphamvu ya Tensile (MPa) |

| 230-380 |

| 250-380 |

| Elongation (%) |

| 2-30 |

| 2-30 |

| Njira yopanga | Extruding-Rolling | Kutulutsa -Kujambula | Extruding-Rolling | Kutulutsa -Kujambula |

5. Mitundu Yogulitsa

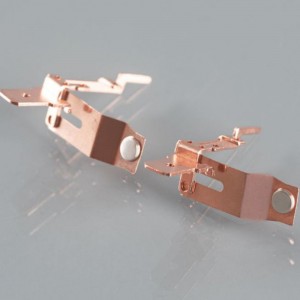

AgNi

1. Microstructure

2. Kufotokozera Zazikulu

Zida za AgNi zimakana kukokoloka kwa arc komanso kuwotcherera kuposa Ag kapena FAg.Katundu onsewa amawongoleredwa ndikuwonjezeka kwa Ni.Zipangizo zonse za AgNi zimawonetsa kugwira ntchito bwino ndipo ndizosavuta kuziwotcherera kuti zilumikizane ndi othandizira.Chizoloŵezi chochepa chotengera kusamutsa zinthu mu mapulogalamu a DC.Zida za AgNi ndizoteteza chilengedwe.

3. Kuchuluka kwa Ntchito

Zipangizo zolumikizirana ndi AgNi zimapeza ntchito zosiyanasiyana pazida zosinthira ma voltage otsika.Amagwiritsidwa ntchito polumikizirana, zolumikizira zing'onozing'ono, zosinthira zowunikira, zowongolera kutentha komanso zotchingira zodzitchinjiriza (zogwiritsidwa ntchito pamagulu olumikizana asymmetric, mwachitsanzo, motsutsana ndi zida zaAgC, AgZnO kapenaAgSnO2).

4. Zinthu Zakuthupi

| Mawaya | AgNi | AgNi | AgNi | Ag Ndi | AgN ndi | AgNi |

| Ndi Content (wt.%) | 10±1 | 12 ±1 | 15 ±1 | 15 ±1 | 20±1 | 30±1 |

| Kuchulukana (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Kulimba kwa HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Mphamvu ya Tensile (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Elongation(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Njira yopanga | Sintering-Extruding | |||||

5. Mitundu Yogulitsa

AgCdO

1. Microstructure

2. Kufotokozera Zazikulu

Magulu a AgCdO ali m'gulu la omwe amagwiritsidwa ntchito kwambiri pazida zamagetsi zamagetsi.Amaphatikiza kukana kokwanira motsutsana ndi kuwotcherera kukhudzana ndi kukana kukokoloka kwa arc komanso kukana kutsika kocheperako pa moyo wake wonse wautumiki.Amapangidwa ndi njira ziwiri zosiyana, pre-oxidation-sintering-extruding ndi makutidwe ndi okosijeni wamkati.Muzochitika zonsezi Cd0 zomwe zili mu Cd0 zitha kukhala kuyambira 10 mpaka 20wt..Pachifukwa ichi kugwiritsa ntchito zinthu zaAgCdO kudzaletsedwa m'maiko angapo.

3. Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri pafupifupi pafupifupi mitundu yonse ya zida zosinthira magetsi otsika.Nthawi zambiri amagwiritsidwa ntchito pa ma microswitches, ma relay, ma switch amagetsi, zolumikizira, zosinthira pazida zapakhomo, mitundu ina ya ma switch oteteza, komanso mitundu ina yamagetsi ozungulira.

4. Zinthu Zakuthupi

| Mawaya | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| CdO Content(wt.%) | 10±1 | 13.5 ± 1 | 15 ±1 | 10±1 | 12 ±1 | 15 ±1 | 17 ±1 |

| Kuchulukana (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Kulimba kwa HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Mphamvu ya Tensile (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Elongation(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Njira yopanga | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||||

5. Mitundu Yogulitsa

AgZnO

1. Microstructure

2. Kufotokozera Zazikulu

Kukana kwakukulu motsutsana ndi kuwotcherera kukhudzana ndi zida za AgZnO.Amawonetsanso kukana kwabwino kwa kukokoloka kwa arc.Kukana kulumikizana kwa AgZnO kumakhala kokwera kuposa kwa AgCd0.AgZnO ikhoza kupangidwa pogwiritsa ntchito pre-oxidation-sintering—extruding, mixing-compacting-sintering komanso ndi makutidwe ndi okosijeni mkati.Zida za AgZnO ndizinthu zoteteza chilengedwe.

3. Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito makamaka pa ophwanya ma circuit, makamaka ophwanya ma circuit.Magawo ena ogwiritsira ntchito ndi ma switch oteteza ma mota, zotsalira zotsalira zapano ndi ma AC relay.

4. Zinthu Zakuthupi

| Mawaya | AgZnO | AgZnO |

| ZnO Content (wt.%) | 8 ±1 | 10±1 |

| Kachulukidwe (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Kulimba kwa HV | E30 | 85 |

| Mphamvu ya Tensile (MPa) | 285-350 | 285-350 |

| Elongation(%) | 15-25 | 12-20 |

| Njira yopanga | Pre-oxidation -Sintering-Extruding | |

5. Mitundu Yogulitsa

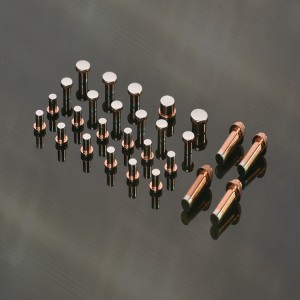

AgSnO2

1. Microstructure

2. Kufotokozera Zazikulu

AgSnO2/AgSn021n203 ndi zida zolumikizirana ndi eco-friendly.Amakhala ndi machitidwe abwino odana ndi kukokoloka ndi anti-kuwotcherera, ndipo ali ndi katundu wabwino wotsutsana ndi zinthu mu DC switching circuit.Waukulu kupanga njira ndi mkati makutidwe ndi okosijeni ndondomeko, chisanadze makutidwe ndi okosijeni ndondomeko, ufa zitsulo ndondomeko, ndondomeko ❖ kuyanika mankhwala, etc..

3. Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri mumitundu yosiyanasiyana yolumikizirana, ma relay, ma breaker ozungulira ndi ma switch, etc.

4. Zinthu Zakuthupi

AgSnO2

| Mawaya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Zamkatimu za SnO2 (wt.%) | 10±1 | 10±1 | 12 ±1 | 12 ±1 | 15 ±1 |

| Kachulukidwe (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Kukaniza (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Kulimba kwa HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Mphamvu ya Tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Njira yopanga | Pre-oxidation-Sintering-Extruding | Kupaka Chemical | Kusakaniza-Sintering-Extruding | ||

AgSnO2In203

| Mawaya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Za Ag (wt.%) | 90±1 | 88 ±1 | 92 ±1 | 88 ±1 | 85.5±1 |

| Kachulukidwe (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kukaniza (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Kulimba kwa HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Mphamvu ya Tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Njira yopanga | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||

5. Mitundu Yogulitsa

AgSnO2In2O3

1. Kufotokozera Kwazonse

2. Microstructure

AgSnO2lAgSn021n203 ndi zida zolumikizirana ndi eco-friendly.Amakhala ndi machitidwe abwino odana ndi kukokoloka ndi anti-kuwotcherera, ndipo ali ndi katundu wabwino wotsutsana ndi zinthu mu DC switching circuit.Njira zazikulu zopangira makutidwe ndi okosijeni mkati, ndondomeko ya pre-oxidation, njira yazitsulo za ufa, ndondomeko yokutira mankhwala, ndi zina zotero.

3. Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri mumitundu yosiyanasiyana yolumikizirana, ma relay, ma breaker ozungulira ndi ma switch, etc.

4. Zinthu Zakuthupi

AgSnO2

| Mawaya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Zamkatimu za SnO2 (wt.%) | 10 ±1 | 10 ±1 | 12 ±1 | 12 ±1 | 15 ±1 |

| Kachulukidwe (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Kukaniza (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Kulimba kwa HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Mphamvu ya Tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Elongation(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Njira yopanga | Pre-oxidation-Sintering-Extruding | Kupaka Chemical | Kusakaniza-Sintering-Extruding | ||

AgSnO2In203

| Mawaya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Za Ag (wt.%) | 90±1 | 88 ±1 | 92 ±1 | 88 ±1 | 85.5±1 |

| Kachulukidwe (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kukaniza (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Kulimba kwa HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Mphamvu ya Tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Elongation(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Njira yopanga | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||