POWDER METAL CONTACTS

| Ntchito: |

| Ma contactor, ma circuit breakers, thermostats, ma switch anzeru, etc |

| Zofunika: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

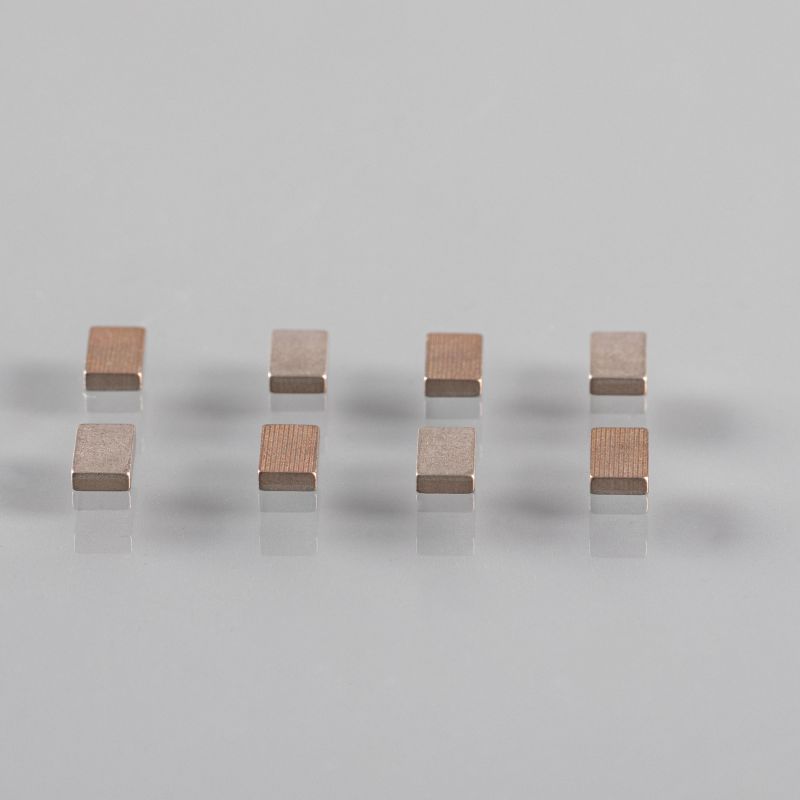

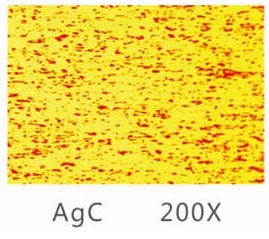

AgC

Microstructure

Kufotokozera Kwambiri

Zida zolumikizirana za AgC zikuwonetsa kukana kwambiri motsutsana ndi kuwotcherera kukhudzana ndi kukana kukhudzana kochepa.Kukana kuwotcherera kumawonjezeka ndi kuchuluka kwa graphite.Zipangizo za AgC zimakhala ndi zodzikongoletsera zokha zikagwiritsidwa ntchito ngati zolumikizira.

Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito makamaka pama switch oteteza monga ma MCB, ma MCCB, ma switch otsalira apano oteteza, kapena ma switch oteteza magalimoto.Ntchito nthawi zambiri imakhala yofanana ndi AgNi, AgW, AgWC kapena Cu.

Zinthu Zakuthupi

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Zomwe zili (wt.%) | 3 ± 0.5 | 4 ± 0.5 | 5 ± 0.5 | 3 ± 0.5 | 3.8±0.5 | 4 ± 0.5 |

| Kachulukidwe (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Kulimba kwa HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Njira yopanga | Sintering-Extruding | |||||

Mitundu Yazinthu

AgW

Microstructure

Kufotokozera Kwambiri

Ma Contacts opangidwa ndi AgW amasonyeza kukana kwakukulu kotsutsana ndi kuwotcherera komanso kukana kwambiri kukokoloka kwa arc chifukwa cha kusungunuka kwapamwamba komanso kuuma kwakukulu kwa W, amakhalanso ndi mphamvu yabwino yamagetsi ndi matenthedwe.

Kuchuluka kwa Ntchito

Zida za AgW zimagwiritsidwa ntchito kwambiri pamagetsi otsika a MCCB ndi ACB komanso ma switch oteteza.

Zinthu Zakuthupi

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Za Ag (wt.%) | 50±2 | 45 ±2 | 40±2 | 35 ±2 | 30±2 | 25 ±2 |

| Kuchulukana (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Kulimba kwa HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Njira yopanga | Kulowa | |||||

Mitundu Yazinthu

AgWC

Microstructure

Kufotokozera Kwambiri

Zida zolumikizirana za AgWC zomwe zili ndi chigawo cha refractory WC zimakhala ndi kulimba kwambiri komanso kukana kuvala kwamakina, chizolowezi chochepa chokhudzana ndi kuwotcherera, komanso kukana kolumikizana kokhazikika muutumiki.Kulumikizana kwa AgWC kumapangidwa ndi kulowetsedwa kwa zitsulo za ufa.

Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri pazida zosinthira zolemetsa, monga ma circuit breakers.zotsalira zamakono zowononga magetsi.Nthawi zambiri amagwiritsidwa ntchito ngati asymmetric machesi ndi AgC

Zinthu Zakuthupi

| AgWC | AgWC | AgWC | AgWC | |

| Za Ag (wt.%) | 65 ±2 | 60±2 | 50±2 | 35 ±2 |

| Kuchulukana (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Kulimba kwa HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Njira yopanga | Kulowa | |||

Mitundu Yazinthu

AgWCC

Microstructure

Kufotokozera Kwambiri

Chifukwa cha kuchuluka kwa Ag, ma AgWCC omwe amalumikizana nawo ali ndi kukana kutsika.Amakhala ndi zinthu zambiri zotsutsana ndi kuwotcherera chifukwa chokhala ndi tungsten carbide ndi graphite yokhala ndi malo osungunuka kwambiri.Zolumikizana za AgWCC zimapangidwa ndi sintering.

Kuchuluka kwa Ntchito

Amagwiritsidwa ntchito kwambiri pazida zosinthira zolemetsa, monga ma circuit breakers.zotsalira zamakono zowononga magetsi.Nthawi zambiri amagwiritsidwa ntchito pamasewera asymmetric ndi AgNi, AgW kapena AgWC.

Zinthu Zakuthupi

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Za Ag (wt.%) | 85 ±1 | 75 ±1 | 79 ±1 | 74.5 ± 1 |

| Kuchulukana (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Kulimba kwa HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Njira yopanga | Mixing-Compacting-Sintering | |||

Mitundu Yazinthu

AgNiC

Microstructure

Kufotokozera Kwambiri

Magulu a AgNiC amaphatikiza zabwino za ma AgNi ndi ma AgC.Amakhala ndi kukana kwabwino kwa kukokoloka kwa magetsi komanso zinthu zotsutsana ndi kuwotcherera.

Kuchuluka kwa Ntchito

Magulu a AgNiC amagwiritsidwa ntchito makamaka ku MCCB, ACB.

Zinthu Zakuthupi

| AgNiC | AgNiC | 3 AgNiC | |

| Za Ag (wt.%) | 67 ±1 | 73 ±1 | 94 ±1 |

| Kuchulukana (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Kulimba kwa HV | ≥50 | ≥60 | ≥30 |

| Njira yopanga | Mixing-Compacting-Sintering | ||

Mitundu Yazinthu

KuW

Microstructure

Kufotokozera Kwambiri

Zida zolumikizirana za CuW zimalimbana bwino ndi kukokoloka kwa arc komanso anti-welding mpaka ma curret apamwamba kwambiri.Zolumikizana za CuW zimapangidwa mosiyanasiyana mosiyanasiyana pogwiritsa ntchito zitsulo zamafuta (kukanikiza / sintering kapena kulowetsa).Zomwe zili mu tungsten ndi 50-80%.

Kuchuluka kwa Ntchito

Zolumikizana za CuW zimagwiritsidwa ntchito kwambiri pama switchgears apakati komanso apamwamba.Ntchito zodziwika bwino zimakhala mu ma voltage breakers, ma switch switch, ma switch switch ma tap osinthira ndi ma arcing otsika ma voltage arcing.

Kuphatikiza apo, zida za CuW zimagwiritsidwa ntchito kwambiri ngati ma electrode, makamaka pakuwotcherera.

Zinthu Zakuthupi

| KuW | KuW | KuW | |

| Cu Content (wt.%) | 50±2 | 40±2 | 30±2 |

| Kuchulukana (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Kulimba kwa HV | ≥115 | ≥140 | ≥175 |

| Njira yopanga | Kulowa | ||

Mitundu Yazinthu