Mkulu-mwatsatanetsatane ndi kusinthasintha zitsulo stamping fakitale

Msonkhano wa Stamping

SHZHJ ili ndi dipatimenti yodziyimira payokha ya R&D ndi gulu la akatswiri odziwa ntchito zamainjiniya.SHZHJ yakhazikitsidwa bwino ngati m'modzi mwa ogulitsa zosindikizira zitsulo zolondola kwambiri.

Studio ya Mold

Ogwira ntchito athu odziwa bwino ntchito adzagwira nanu mbali zonse zazitsulo zachitsulo.Kuchokera pakupanga, prototyping, FAI, PPAP, kupanga voliyumu yotsika mpaka kupondaponda kwapakati komanso kwakukulu, tidzapanga zigawo zomwe zikugwirizana ndi zomwe mukufuna.

Zogulitsa

Zida zogwiritsira ntchito

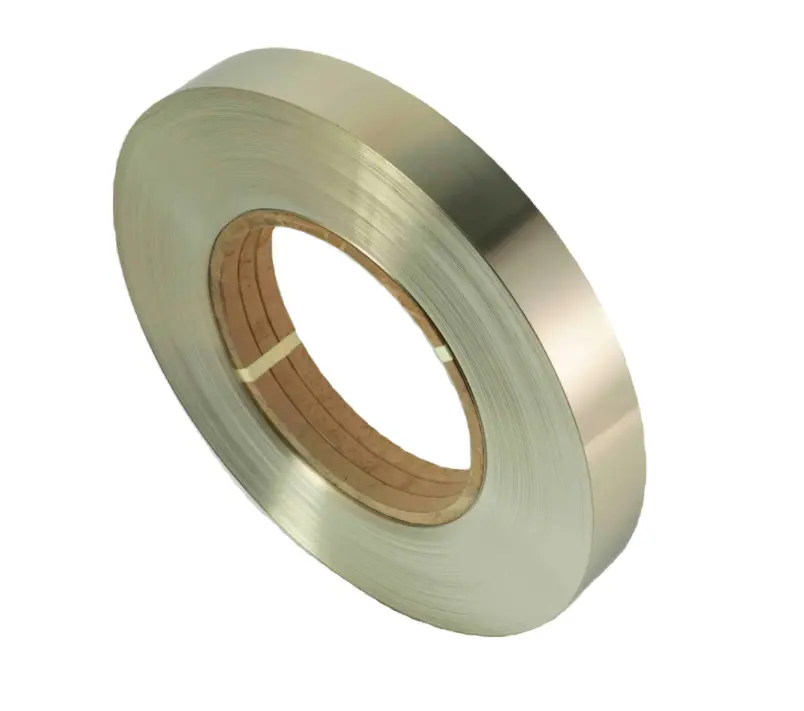

SHZHJ imagwiritsa ntchito zipangizo zosiyanasiyana kuti apange zinthu zosiyanasiyana zamtengo wapatali malinga ndi zofunikira za mafakitale osiyanasiyana.Mzere Wosavuta ndi kusindikizira kwa nsalu zilipo.Kuchuluka kwa zinthu ndi 5μm mpaka 5mm.

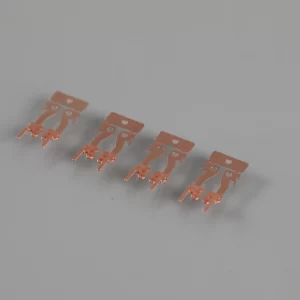

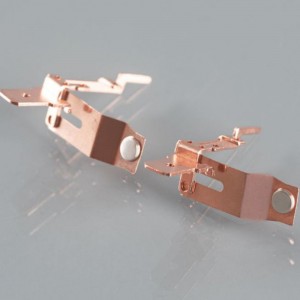

- Mkuwa

- Mkuwa wamkuwa

- Beryllium mkuwa

- Mkuwa woyera

- Aluminiyamu

- Chitsulo

- Nickel weniweni

- Pre-nickel kapena pre-tin plated materials

- Zofuna za makasitomala apadera

PRECISION METAL STAMPING CAPABILITS

Progressive Die Stamping ndi:

Mu Die Tapping ndi Inserted Threaded

Mu Die Assembly

Mu Die Roll Forming ndi Dovetail Interlocked

Zojambula Zakuya Zopita patsogolo

Choka Chojambula Chozama

Transfer Stamping / Kupanga pa Extruded & Pre-Machined Tube

Reel to Reel Stamping

Njira yosindikizira ya SHZHJ imagwiritsa ntchito makina osindikizira azitsulo apamwamba kwambiri (robotic, manual kapena mizere yopita patsogolo), makina athu osindikizira amachokera ku matani 45 mpaka 400, zipangizo za CNC zimagwiritsidwa ntchito limodzi ndi mayunitsi apadera, ma jigs ndi ma fixtures kuti apange mwambo. zitsulo Stamping.Magawo a mawonekedwe aliwonse amatha kukhomeredwa, kukhomeredwa, kupangidwa, kujambulidwa, kujambula ndi kutulutsa.

Ntchitozi zimathandizidwa ndi kuthekera kokulirapo kwachiwiri, kuphatikiza makina amakina, riveting, tapping ndi kuwotcherera, deburring, degreasing ndi zosankha zosiyanasiyana zamapaketi.

Chifukwa chiyani musankhe SHZHJ -- masitampu kupanga

♦ Malingana ndi zofunikira zojambula, yesani mawonekedwe ndi makina azinthu zazitsulo kuti muwonetsetse kuti zipangizozo zikukwaniritsa zofunikira.

♦ Kutengera ndi kafukufukuyu, tikuwunika mafayilo a 2D ndi 3D omwe ali ndi chidziwitso chofunikira kuphatikiza zida, zololera, miyeso yovuta komanso kumaliza.Kutengera ndi magawo, dipatimenti ya nkhungu imapanga mapangidwe osiyanasiyana opanga zinthu.

♦ Njira yopondaponda yachitsulo imayamba ndi pepala lachitsulo lathyathyathya kapena chubu lachitsulo.Amalowetsedwa m’makina oyenera osindikizira, omwe amaumba chitsulocho pokhomerera, kutseka kanthu, kapena kupondaponda.Kupondaponda kwachitsulo kungaphatikizepo masitampu agalimoto, masitampu achipatala, kapena masitampu ena, ndipo angafunike masitampu angapo kutengera gawo lake.

• Zigawo zambiri zosindikizidwa zimafuna chithandizo chapamwamba.Zigawo zambiri zosindikizidwa zimafunikira plating kapena zofunikira zina pambuyo pokonza kuti ziteteze gawolo ku chilengedwe ndikuwonetsetsa kuti zinthu zizikhala ndi moyo wautali.

♦ Panthawi yopangira, dipatimenti ya QC idzayang'ana koyamba / kuyendera / kuyang'anira komaliza kwa mankhwala kuti atsimikizire kuperekedwa kwa zinthu zodalirika.