-

Cost

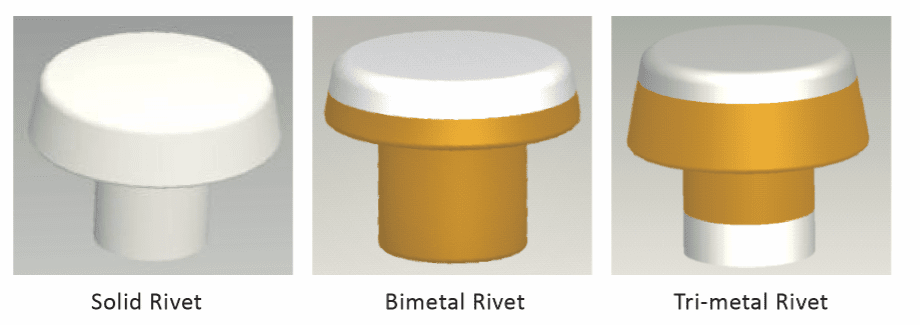

1) Compared with solid rivets, trimetal rivets can significantly save the number of precious metal materials and reduce costs by using cheaper materials in non-critical parts while ensuring performance. For example, in some electrical switches, replacing solid rivets with trimetal rivets can save about 60% of silver materials, which is a significant cost-saving effect for large-scale production companies.

2) Although bimetal rivets can also save precious metals to a certain extent, their saving effect is usually not as obvious as that of trimetal rivets. Bimetal rivets mainly use different materials to composite a certain layer or part of the area of the rivet, and the cost reduction is relatively small.

-

Performance

- Solid rivets are made of a single material and have relatively simple performance. If precious metal materials are used to make integral rivets, although good electrical contact performance can be guaranteed, the cost is high; if ordinary metal materials are used, they may not perform well in terms of electrical contact performance or wear resistance in some special requirements.

- Bimetal rivets may be slightly weaker than those of trimetal rivets. They are usually made by combining a material with better performance with another material on the main contact surface of the rivet to improve performance and reduce costs to a certain extent. However, in some occasions with extremely high-performance requirements, they may not be able to fully meet the needs.

Post time: Sep-09-2024