When rivet, if rivet diameter is too large, upsetting forming is more difficult, easy to make sheet metal deformation.On the contrary, if the diameter of the rivet is too small, the strength of the rivet is insufficient, resulting in the increase of the number of rivets and the inconvenience of construction.

How to choose the diameter of the rivet needs to see the size of the aperture of the rivet. Generally, the diameter of the rivet is 0.1-0.2mm larger than the diameter of the rivet. If it is more than 0.2mm, it may become loose.

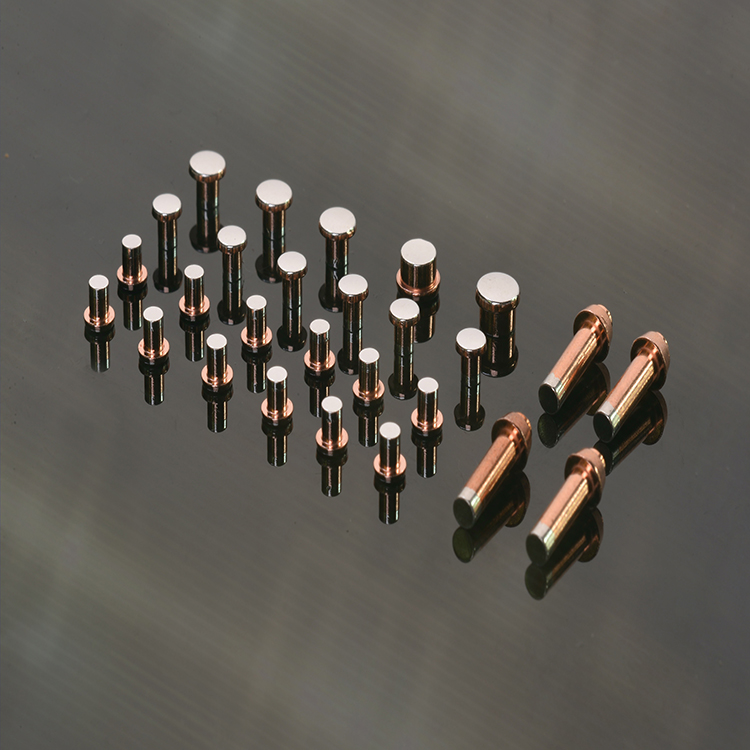

The choice of rivet diameter is mainly determined by plate thickness and rivet form.The quality of rivet is directly related to the length of nail rod. If the nail rod is too long, the upset head of rivet will be too large, and the nail rod will be easy to bend.However, if the nail rod is too short, the upsetting amount is insufficient and the rivet head is incomplete, which will seriously affect the strength and tightness of rivet joint.The riveting length should be determined according to the total thickness of the connected parts, the diameter clearance between nail hole and nail rod and the riveting process.The rivet rod length with standard aperture can be calculated according to the formula of rivet joint form, and the plate thickness in calculating the rivet diameter must also be determined according to the principle.

The matching of rivet aperture and rivet should be determined according to different ways of cold rivet and hot rivet.The nail rod is not easy to be upset during cold riveting. In order to ensure the connection strength, the diameter of the nail hole should be close to that of the nail rod.In hot riveting, because the rivet expands in heat, the rivet’s plasticity increases and its hardness decreases. In order to facilitate threading, the difference between the diameter of the nail hole and the nail rod should be slightly larger.For multi-layer plate dense riveting, the diameter of the drill hole should be reduced by 1-2mm as the standard diameter. For cylindrical components, the hole diameter should be reduced by L-2mm as compared with the standard diameter before bending, so that reaming can be carried out in accordance with the technical requirements during assembly.

Rivet hole technical requirements include rivet hole precision, position precision and surface quality.The precision of rivet hole refers to the dimension precision of rivet hole diameter and length direction, as well as the shape precision of rivet hole diameter such as roundness, cylindricity and axis straightness, and also includes the precision of the hole on the socket of countersunk head rivet hole.The position accuracy of rivet holes mainly reflects the coaxiality between rivet holes, the flatness between nail holes and the surface flatness between nail holes and the edge of rivet pieces.The rivet hole spacing, margin and row spacing precision requirements should be determined according to the rivet alignment parameters on the rivet.

Generally, when the spacing between nail holes is no more than 30mm, the spacing deviation is ±1.0mm.When the spacing between nail holes is greater than 30mm, the spacing deviation is ±1.5mm.The margin and row spacing deviation of rivet holes are generally ±1.0mm.The surface quality of the rivet hole mainly refers to the surface roughness requirement of the internal surface of the rivet hole, and the surface of the nail hole is not allowed to have burrs, edges and corners, damages and cracks.

Post time: Nov-25-2020