When it comes to conducting electricity, silver and copper are often at the forefront of the conversation. Both are excellent conductors, but which one reigns supreme? This article delves into the fascinating world of electrical conductivity, comparing silver wire and copper wire to determine which electrical conductor truly performs better. Understanding these differences is crucial for various applications, from household wiring to high-tech electronics. So, is it better to use silver or use copper? Read on to find out!

1. Silver vs. Copper: Directly Comparing Electrical Conductivity – Which Metal Leads?

When we talk about electrical conductivity, we’re essentially measuring how well a material allows electricity to flow through it. Think of it like water flowing through a pipe; a wider, smoother pipe allows more water to pass with less resistance. In the world of metals, silver stands out as the best conductor of electricity. In fact, pure silver boasts the highest electrical conductivity of all metals. Copper, while not quite as conductive as silver, comes in a close second. Studies show that silver is approximately 7-25 times more conductive than other common conductive materials when considering bulk conductivity, whereas copper follows closely behind, showcasing conductivity levels around 7-20 times higher than those of many alternatives. This difference, while measurable, often leads to the question: does this slight edge of silver make a significant difference in everyday electrical wires?

The difference in conductivity between silver and copper comes down to their atomic structure and how easily their electrons can move. Silver has more free electrons that can carry an electrical charge, making it a more efficient pathway for electricity. However, this difference in performance, while scientifically significant, isn’t always practically noticeable in many common electrical applications. For standard electrical wires in homes and appliances, the slightly lower conductivity of copper is often perfectly acceptable and doesn’t significantly impede the flow of electricity. This is why you may find copper wires made in most household electrical systems.

2. Why Does Silver Exhibit Superior Electrical Conductivity Compared to Copper?

The superior electrical conductivity of silver stems from its unique atomic structure. Metals conduct electricity through the movement of electrons. In silver, the outermost electron shell is more readily available for these electron movements. This abundance of highly mobile electrons translates directly to a lower resistance to electrical current. Imagine a highway with more lanes and less traffic – that’s essentially what’s happening at the atomic level in silver. Electrons can flow more freely and efficiently. When comparing silver and copper, silver simply offers a less obstructed path for the flow of electrons, making it the better conductor.

Copper, with its slightly different atomic arrangement, still provides a very good pathway for electrons, but it encounters a touch more resistance. This difference is measurable and quantifiable. For instance, if we were to measure the resistance of a silver wire and a copper wire of the same dimensions, the silver wire would exhibit a lower resistance, indicating its superior ability to conduct electricity. This fundamental difference at the atomic level is why, though silver is the top performer, copper is used so widely due to other factors like cost and availability.

3. Considering Cost: Is the Higher Cost of Silver Justified for Electrical Use Silver Applications?

The most significant factor limiting the widespread use of silver in electrical applications is its high cost. Silver is a precious metal, and its price is considerably higher than copper. This higher cost makes the mass production of electrical wires and components using silver economically impractical for most general purposes. While the performance of silver is undeniably superior in terms of conductivity, the marginal gain in efficiency often doesn’t justify the significantly higher expense for standard applications.

Therefore, while engineers and designers acknowledge the superior electrical conductivity of silver, the pragmatic reality of manufacturing often favors copper. Copper is widely available and relatively abundant, making it a far more cost-effective choice for the vast majority of electrical applications. Think about the sheer volume of electrical cables and wires used globally – switching to silver would represent a massive increase in raw material costs. This is why, compared to copper, silver sees much more limited use, primarily in niche applications where its superior conductivity provides a critical advantage that outweighs the high cost.

4. Oxidation and Corrosion: Does Copper or Silver Hold Up Better Over Time?

Another crucial aspect to consider for electrical conductors is their resistance to oxidation and corrosion. Copper, when exposed to air and humidity, undergoes oxidation, forming a layer of copper oxide on its surface. This oxide layer, while somewhat conductive, does increase resistance over time and can hinder the flow of electricity, especially at contact points. This is why you might see a greenish tarnish on older copper wire or copper core cables.

Silver, on the other hand, is remarkably resistant to oxidation. It doesn’t readily react with oxygen in the air under normal conditions. However, silver can tarnish when exposed to sulfur compounds, forming silver sulfide. While this tarnish is also a form of corrosion, it generally has less impact on electrical conductivity compared to copper oxide. Therefore, in terms of long-term stability and resistance to degradation that significantly impacts conductivity, silver generally holds up better than copper. This inherent corrosion resistance is another advantage of silver, particularly in sensitive electronics where maintaining consistent signal integrity is paramount.

5. For What Specific Applications Is Silver Wire Typically Chosen Despite the Higher Cost?

Despite silver’s high cost, its exceptional electrical conductivity and corrosion resistance make it the preferred choice for certain specialized applications. In high-end audio equipment, for example, silver wire is often used in cables and connectors to minimize signal loss and maintain the purity of the audio signal. The discerning audiophile might perceive a difference in sound quality due to the enhanced conductivity.

Silver also finds significant application in sensitive electronics, particularly in medical devices and aerospace engineering where reliability and consistent performance of silver are critical. In these scenarios, the cost is secondary to ensuring optimal functionality. You may find silver in specialized electrical contacts where even a slight increase in resistance could be detrimental. Furthermore, silver solder is often used for joining delicate electronic components due to its excellent conductivity and relatively low melting point. The use of silver in these niche areas highlights that when absolute conductivity is paramount, the higher cost becomes a necessary investment.

6. Where is Copper Wire, Being More Affordable, the Standard Electrical Conductor?

The affordability and good electrical conductivity of copper make it the undisputed champion for most general electrical applications. From the electrical wiring in our homes and offices to the power lines transmitting electricity across vast distances, copper wire is the workhorse of the electrical industry. Its cost-effectiveness, combined with its excellent conductivity, makes it the ideal material for mass-produced electrical cables, appliance cords, and the internal wiring of countless electronic devices.

The readily available supply of copper and well-established manufacturing processes further solidify its position as the standard. While aluminum wire is sometimes used as a cheaper alternative for certain high-voltage applications, copper remains the preferred choice for most low- to medium-voltage applications due to its superior conductivity and ease of use. When considering the sheer scale of the electrical infrastructure worldwide, the economic advantage of copper becomes undeniably clear. You’ll generally find copper is used in any situation where a balance of good conductivity and reasonable cost is required.

7. What Role Does Silver Plate or Coating Play in Electrical Contact Applications?

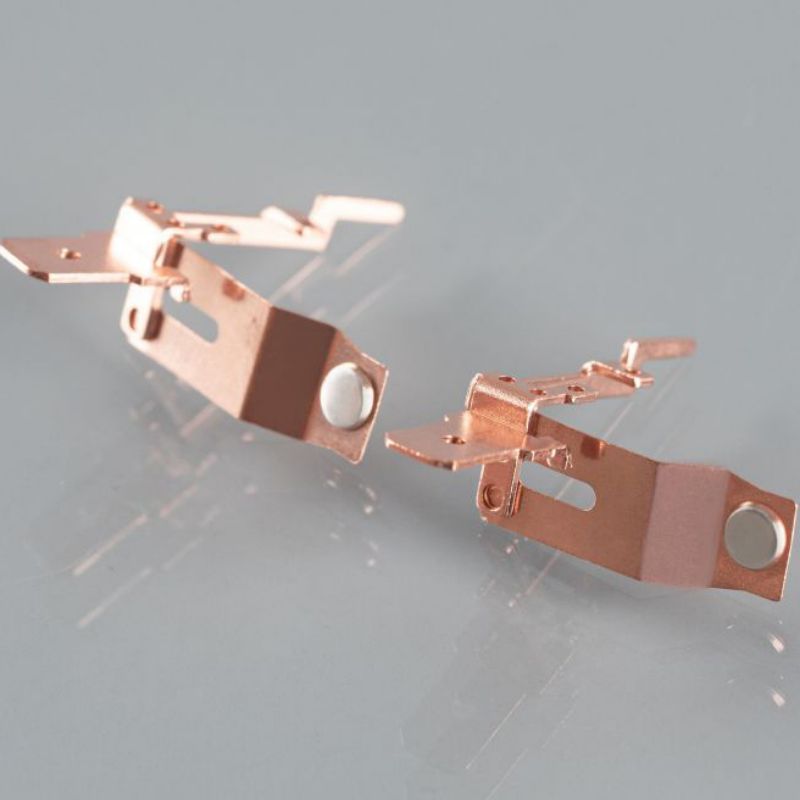

To leverage the benefits of silver’s superior conductivity without the prohibitive cost of using solid silver, silver plate or coating is a common practice, particularly in electrical contact applications. Thin layers of silver are applied to the surface of other, more cost-effective conductive metals like copper or brass. This provides the excellent surface conductivity of silver at the point of contact, where it matters most for efficient electricity transfer.

This technique is frequently employed in contact rivets, switches, relays, and connectors. The silver layer ensures a low-resistance contact point, minimizing energy loss and heat generation. Furthermore, the corrosion resistance of silver helps maintain a reliable electrical connection over time, even in harsh environments. Think of it as getting the best of both worlds – the superior surface properties of silver without the overall expense of a solid silver component. Our Contact Rivets, available at https://www.shzhj.com/solid-contact-rivets-product/, often utilize this principle for optimal performance. Similarly, Trimetal Contact Rivets and Bimetal Contact Rivet, found at https://www.shzhj.com/tri-metal-contact-rivet-product/ and https://www.shzhj.com/bimetal-contact-rivet-product/, respectively, utilize strategic material layering to achieve desired electrical and mechanical properties.

8. Are There Instances Where Aluminum Enters the Silver and Copper Conductor Discussion?

While silver and copper are the primary players in high-conductivity applications, aluminum does enter the conversation, particularly in scenarios where weight and cost are major concerns. Aluminum is significantly lighter and less expensive than copper, although its electrical conductivity is lower. Therefore, aluminum wire is often used for high-voltage overhead power lines where the reduced weight minimizes stress on support structures.

However, aluminum has its drawbacks. It’s more prone to oxidation than copper, forming a non-conductive oxide layer. This necessitates special connectors and installation techniques to ensure reliable electrical connections. You may find aluminum used in some building wiring, but it requires careful installation to prevent fire hazards due to its expansion and contraction properties. While aluminum offers a cost-effective alternative in specific situations, copper generally remains the preferred choice where high conductivity and ease of use are paramount. The choice between aluminum, copper, and silver often involves a trade-off between conductivity, cost, weight, and other specific application requirements. Even our Contact Assemblies, detailed at https://www.shzhj.com/contact-assy-product/, consider these material trade-offs for optimal design.

9. What are the Key Properties That Make a Material a Good Electrical Conductor?

Several key properties determine how well a material functions as an electrical conductor. The most important is the availability of free electrons. Materials with loosely bound outer electrons, like silver and copper, allow these electrons to move easily, carrying an electrical charge. This ease of electron movement directly translates to high electrical conductivity.

Low resistance is another crucial property. A good conductor offers minimal opposition to the flow of electricity, reducing energy loss in the form of heat. Silver excels in this regard, having the lowest resistance among common metals, followed closely by copper. Other important properties include ductility (the ability to be drawn into wires), malleability (the ability to be hammered into thin sheets), and corrosion resistance. While silver and copper are both relatively ductile, their differences in corrosion resistance, as discussed earlier, can influence their suitability for specific applications. The density of the material also plays a role, particularly in applications where weight is a concern.

10. Beyond Wires Made of Copper and Silver: Exploring Other Conductive Materials.

While silver and copper are the most widely recognized conductive metals, the world of conductive materials extends beyond them. Gold, for example, boasts excellent conductivity and corrosion resistance, making it ideal for high-reliability electrical contacts in demanding applications, although its even higher cost limits its widespread use.

Other conductive materials include aluminum, as discussed, and various alloys designed for specific electrical properties. Semiconductors, like silicon, have unique conductive properties that can be controlled by adding impurities, forming the basis of modern electronics. Even carbon, in forms like graphene and carbon nanotubes, exhibits remarkable electrical conductivity and is being explored for future electrical applications. The choice of conductive metal ultimately depends on the specific requirements of the application, balancing factors like conductivity, cost, weight, and environmental considerations.

Key Takeaways:

- Silver is the best conductor of electricity, followed closely by copper.

- The high cost of silver limits its use to specialized applications where superior conductivity is critical.

- Copper is the standard electrical conductor for most general applications due to its good conductivity and affordability.

- Silver plating is often used in electrical contacts to provide the benefits of silver’s conductivity at a lower cost.

- Aluminum is a lighter and cheaper alternative for certain high-voltage applications, but it has lower conductivity and is more prone to oxidation.

- The choice of electrical conductor involves balancing conductivity, cost, weight, and other specific application requirements.

For high-quality Contact Rivets, Electrical Contact Tips, Silver Alloy Wires, and other precision electrical components, feel free to explore our offerings at https://www.shzhj.com/. We provide customized solutions to meet your specific needs.

Post time: Dec-31-2024