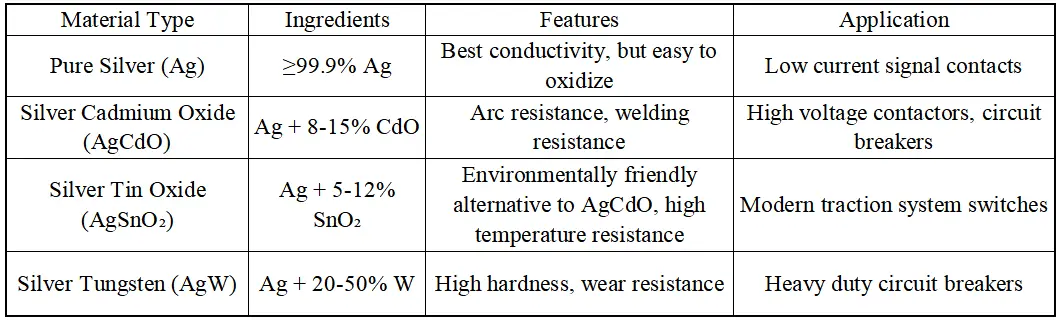

In train (railway) systems, silver contacts are widely used in key components such as electrical control, signal transmission and power distribution, mainly due to their excellent conductivity, arc resistance and oxidation resistance. The following are the material property requirements for silver contacts

- High conductivity: pure silver or silver alloys (such as AgCdO, AgSnO₂) reduce contact resistance.

- Arc erosion resistance: adding metal oxides (such as CuO, Ni) to improve ablation resistance.

- Mechanical strength: silver-based composite materials (such as AgW) are used for high-load components.

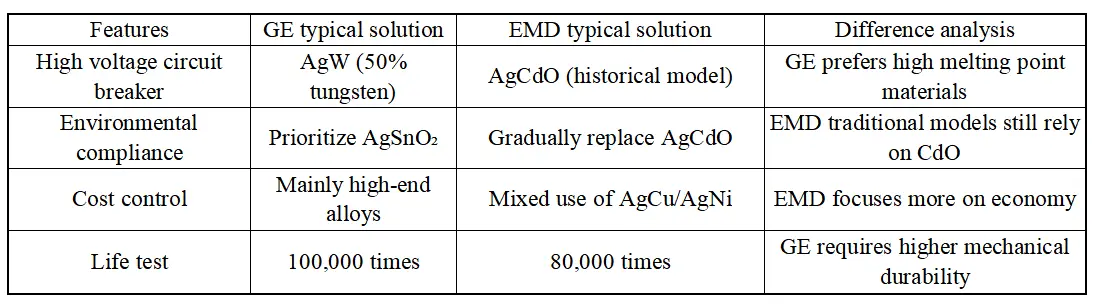

Take the application of silver contacts by GE (General Electric) and EMD (Electro-Motive Dies) as an example. The following is a comparative analysis and typical applications of the two major manufacturers:

I.GE (General Electric) locomotivecontacts

1.Application scenarios

(1) Traction system:

Main circuit breaker (such as GE’s AK series circuit breaker): Adopt AgW (silver tungsten) contacts, resistant to high voltage arc (≥25kV).

Contactor (such as GEC Alstom’s CPC series): Commonly use AgSnO₂ (silver tin oxide), which is environmentally friendly and resistant to welding.

(2) Auxiliary power supply:

Relay contacts (such as GE’s MM series): Use AgNi (silver nickel), suitable for low current scenarios with frequent switching.

2.Material preference

(1) High voltage and high current scenarios: AgW (containing 30%-50% tungsten) or AgC (silver graphite).

(2) Medium and low voltage control circuits: AgSnO₂ (replacing traditional AgCdO to comply with RoHS).

II. EMD (Progress Rail) locomotivecontacts

1.Application Scenarios

(1) Diesel Locomotive Control Systems:

Starter Contactors (such as the EMD 1010 Series): Use AgCdO (silver cadmium oxide), resistant to high surge currents (historical models still retain this material).

Brake Solenoid Contacts: Use AgCu (silver copper), balancing cost and conductivity.

(2) Modern Hybrid Systems:

Inverter Switches: Gradually turning to AgSnO₂-In₂O₃ (doped with indium to improve oxidation resistance).

2.Material Preferences

Traditional diesel locomotives: AgCdO (high arc resistance, but subject to environmental restrictions).

New Locomotives: AgSnO₂ or AgZnO (compliant with EPA/TSCA requirements).

Post time: Mar-25-2025