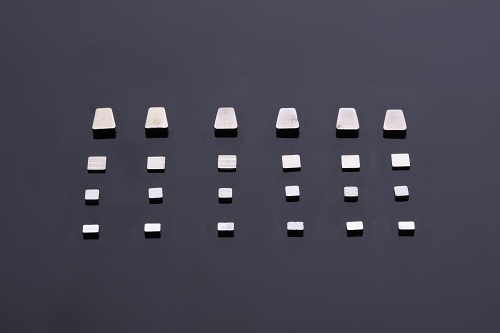

The composition and quality of contact products prepared by powder metallurgy are easier to control than other process methods, ensuring the consistency of contact tips performance. The main materials include AgC, AgW, AgWC, etc.

1.AgC has high resistance to welding and low contact resistance. As the graphite content increases, its resistance to welding increases. Silver graphite material has self-lubricating properties when used as a sliding contact tips. It is mainly used for protection switches, such as miniature circuit breakers MCB, molded case circuit breakers MCCB, leakage protection switches or motor protection switches, and often forms asymmetric paired contact tips with AgNi, AgW, AgWC or Cu.

2.AgW have high resistance to welding and arc corrosion due to the high melting point and hardness of tungsten. They also have good electrical and thermal conductivity. AgW contact tips are mainly used for low-voltage molded case circuit breakers and universal circuit breakers as well as protection switches.

3.AgWC has high hardness, small mechanical wear, small welding tendency, and relatively stable contact resistance.Mainly used for high-load switchgear, such as circuit breakers and leakage switches.In many cases, it is used as an asymmetric pair of contacts tips with AgC.

Powder metallurgy technology is widely used in the manufacture of various metal parts, tools, bearings, gears, etc., especially in the manufacture of parts with complex shapes and special performance requirements.

Post time: Aug-22-2024