Are you searching for electrical contacts that offer exceptional performance and reliability? This article dives deep into the world of silver alloy (AGW) powder metallurgy, exploring how this advanced manufacturing process creates contact tips and other critical components with superior conductivity and arc erosion resistance. Learn why choosing the right contact material is crucial and how our expertise as a leading supplier can benefit your business.

What Makes Our Electrical Contact Product Description Stand Out?

At the heart of reliable electrical systems lies the crucial electrical contact. Our product description goes beyond simple specifications, highlighting the meticulous engineering and superior materials that define our offerings. We specialize in electrical contact materials, particularly those made with silver alloy (AGW). What sets our contacts apart? It’s the combination of high-purity materials and advanced manufacturing techniques, primarily powder metallurgy. This process allows for the creation of complex shapes and precise compositions, leading to contact tips and other components with exceptional good electrical and thermal conductivity. Our agw contacts, whether in the form of agw powder or solid components, are engineered for consistent performance and longevity. You’ll find details and price information readily available, showcasing our commitment to transparency and value.

Our electrical contact materials are rigorously tested to ensure they meet the demanding needs of various applications. From intricate contact rivets to robust metal contact components, we provide solutions that enhance the overall efficiency and lifespan of your products. The use of powder metallurgy ensures a homogenous material structure, which is vital for consistent conductivity and resistance to wear and tear. We aim to be more than just a supplier; we strive to be a trusted partner, providing electrical contacts that deliver tangible benefits to your operations.

Why is Metal Contact Material Choice Critical for Low Voltage Applications?

Even in low voltage applications, the selection of the metal contact material is paramount for reliable performance. While the electrical stress might be less intense compared to high-power systems, factors like corrosion resistance and low contact resistance remain critical. Silver alloy contacts are often preferred in these scenarios due to their excellent conductivity and inherent resistance to oxidation. An oxidized contact can lead to increased resistance, heat buildup, and ultimately, failure of the component. Our silver alloy wire and silver alloy based contacts are designed to maintain a low and stable resistance throughout their operational life, ensuring consistent and efficient energy transfer.

Consider a timer of a washer. A seemingly simple application, but the repeated opening and closing of the circuit demands a reliable electrical contact. Using inferior contact material can lead to premature failure and costly repairs. Our agw contacts, including agw contact tip designs, are engineered to withstand these repetitive cycles while maintaining their electrical integrity. The composition and quality of contact materials directly impact the longevity and performance of the end product. Therefore, choosing a high-quality silver alloy contact is a smart investment for long-term reliability in low voltage systems.

How Does Powder Metal Technology Enhance Electrical Contact Performance?

Powder metallurgy is a game-changer in the manufacturing of high-performance electrical contacts. This process involves pressing fine metal contact powders into a desired shape and then sintering them at high temperatures. Unlike traditional casting or machining, powder metallurgy allows for the precise control of material composition and microstructure. For instance, creating a powder contact with a specific ratio of silver and another metal like nickel (agni) becomes significantly more accurate. This precise control is crucial for optimizing the electrical function of contact materials, including attributes like arc erosion resistance.

The benefits of powder metallurgy extend beyond compositional control. It also allows for the creation of complex and intricate shapes, which is often challenging or impossible with traditional methods. This is particularly advantageous for manufacturing specialized contact tips or contact component designs. Furthermore, the sinter process creates a dense and homogenous material structure, which enhances the good electrical and thermal conductivity of the contact. For applications demanding high reliability and performance, electrical contacts produced by powder metallurgy offer a clear advantage. This technique is especially beneficial when working with materials like agw powder, ensuring uniform distribution and optimal properties in the final product.

What are the Key Advantages of Powder Metal Contacts in Heavy-Duty Applications?

In demanding, high voltage and heavy charge applications, the robustness of powder metal contacts truly shines. The inherent material properties achieved through powder metallurgy, such as increased density and controlled microstructure, contribute significantly to their performance under stress. For instance, in high electricity charge switchgear, contacts are subjected to significant electrical loads and potential arcing. Powder metallurgy contacts, especially those made with agw powder metallurgy and reinforced with elements like tungsten carbide, exhibit superior arc erosion resistance. This means they can withstand the intense heat and electrical discharge without significant degradation, extending their lifespan and reducing maintenance requirements.

Our powder metal contacts are engineered to meet the rigorous demands of industries like railway equipment manufacturing, where reliable locomotive contact performance is paramount. The ability to precisely control the alloy composition allows us to tailor the contact properties to specific application needs. For example, adding tungsten can further enhance the arc erosion properties, while carefully adjusting the silver content ensures optimal conductivity. Whether it’s for protective switch applications or other high-demand scenarios, our powder metal contacts deliver consistent and dependable performance. This technology also facilitates the creation of tri metal contact designs, combining different materials to optimize specific performance characteristics.

Understanding Weld Resistance in High-Quality Electrical Contacts: Why Does it Matter?

Weld resistance is a critical characteristic of high-quality electrical contacts, particularly in applications involving significant electrical arcing. When a circuit breaks, the electrical energy can create intense heat, potentially causing the contact surfaces to fuse or weld together. This phenomenon, known as contact welding, can lead to equipment malfunction and safety hazards. Therefore, selecting contact materials with excellent fusion welding resistance is essential. Our agw contacts, formulated with specific alloy compositions, are designed to minimize the risk of welding.

Powder metallurgy plays a crucial role in enhancing weld resistance. The homogenous microstructure achieved through this process contributes to a higher melting point and improved thermal conductivity, allowing the contact to dissipate heat more effectively and reducing the likelihood of welding. Furthermore, specific alloy additions, like certain metal oxides, can further improve the anti-welding properties of the contact tip. Our commitment to utilizing advanced technology in our manufacturing process ensures that our electrical contacts offer superior weld resistance, contributing to the overall safety and reliability of your electrical systems. This is particularly important in protective switch applications where the contacts must reliably interrupt high currents.

Why is Choosing the Right Supplier Crucial for Your Contact Rivet Needs?

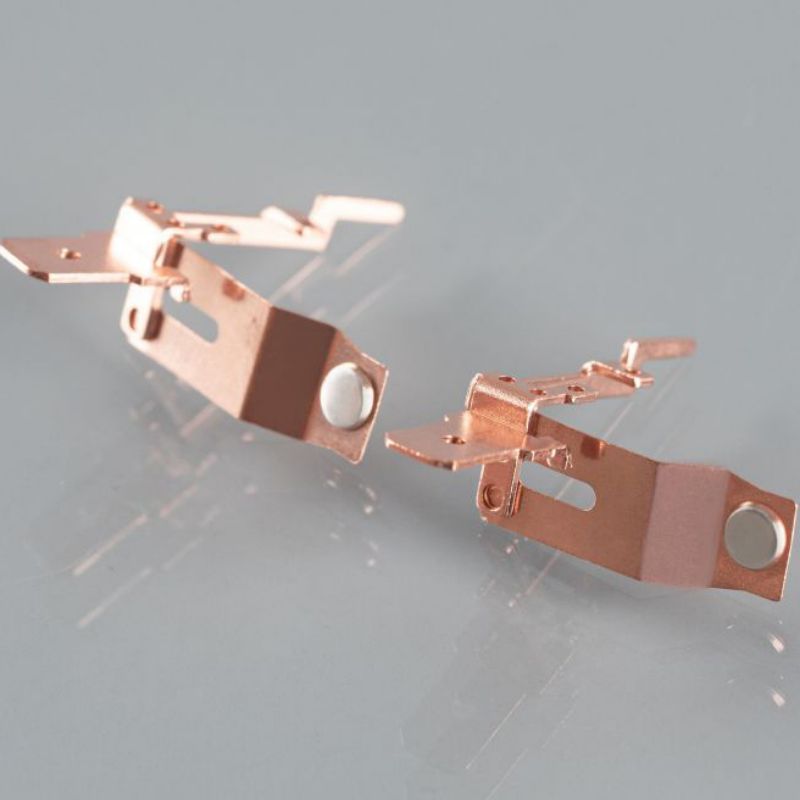

Selecting the right supplier for your contact rivet needs is a decision that significantly impacts the quality and reliability of your final product. As a factory specializing in electrical contacts and precision machined components, we understand the critical role these small but essential parts play. Choosing a reputable supplier like us ensures you receive contact rivets manufactured to the highest standards, with consistent dimensions and material composition. We offer a diverse range of contact rivets, including bimetal contact rivet, tri metal contact rivet, and solid contact rivets, catering to a wide array of applications.

Our commitment to quality extends beyond the manufacturing process. We prioritize clear and efficient communication, addressing potential pain points such as inefficient communication with supplier sales representatives. We understand the concerns of customers like Mark Thompson, who values both quality and competitive pricing. Partnering with a direct manufacturer allows us to offer cost-effective solutions without compromising on quality. Whether you require standard contact rivet designs or customized profiles, we have the expertise and production capabilities to meet your specific requirements. We are a leading manufacturer of electrical contact solutions, dedicated to providing reliable and high-performing components.

What Makes Our Contact Tip Solutions a Reliable Choice for Diverse Applications?

Our contact tip solutions are engineered for reliability and performance across a wide spectrum of applications. Utilizing powder metallurgy, we create contact tips with precise geometries and optimized material compositions. Whether you require contact tips for high voltage circuit breaker applications or sensitive low voltage electronics, we have a solution to meet your needs. Our expertise in working with various contact materials, including silver alloy, agni, and other specialized electrical alloys, allows us to tailor the contact tip properties for specific performance requirements.

The reliability of our contact tip solutions stems from our rigorous quality control processes and our commitment to using high-purity materials. We understand that even minor variations in material composition or dimensions can impact the performance and lifespan of the electrical contact. Therefore, we adhere to strict tolerances and conduct thorough testing to ensure consistency and ameliorate electrical function of contact. Our contact tips are designed to provide excellent conductivity, minimize arc erosion, and offer superior weld resistance, contributing to the overall reliability of your electrical devices. We are a trusted supplier for businesses seeking high-performance contact tip solutions.

How Do Different Alloys, Including Silver Alloy and Clad Metal, Impact Contact Performance?

The choice of alloy directly influences the performance characteristics of electrical contacts. Silver alloy, with its excellent conductivity and corrosion resistance, is a common choice for many applications. However, different alloying elements can further enhance specific properties. For instance, adding nickel to silver (agni) improves weld resistance and hardness, making it suitable for applications involving frequent switching. Understanding these nuances is crucial for selecting the optimal contact material.

Clad metal technology offers another approach to optimizing contact performance. This involves bonding layers of different metals together to combine their beneficial properties. For example, a clad metal contact might have a silver-rich surface for excellent conductivity backed by a copper layer for improved mechanical strength and heat dissipation. This approach can be particularly cost-effective while still delivering high performance. We offer both solid alloy and precious clad metal contact solutions, providing flexibility to meet diverse application requirements and budgetary considerations. The selection between different alloys and clad metal options depends heavily on the specific demands of the application, including voltage, current, switching frequency, and environmental conditions.

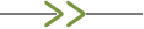

Exploring the Versatility of Silver Alloy Wire in Electrical Components.

Silver alloy wire is a versatile material widely used in various electrical components due to its exceptional electrical and thermal conductivity. The addition of other metals to silver enhances its mechanical properties and arc erosion resistance, making it suitable for demanding applications. Our silver alloy wires are manufactured with precise control over the alloy composition to ensure consistent performance. They are used in the production of various electrical contacts, including contact rivets and specialized contact assemblies.

The high conductivity of silver alloy wire minimizes energy loss and heat generation, contributing to the efficiency and longevity of electrical devices. Its inherent resistance to corrosion ensures reliable performance even in harsh environments. We provide silver alloy wire in various diameters and compositions to meet the specific requirements of our customers. From fine wires used in delicate electronic components to thicker wires for high-current applications, our silver alloy wire solutions offer consistent quality and performance. You can find our contact products and other offerings showcased on platforms like product on alibaba.com, highlighting our reach and commitment to serving a global clientele.

How Can You Benefit from Partnering with a Leading Electrical Contact Manufacturer?

Partnering with a leading manufacturer of electrical contact materials like us offers numerous advantages. With multiple production lines and a commitment to quality, we can ensure a stable and reliable supply of electrical contacts to meet your production demands. Our expertise in powder metallurgy and other advanced manufacturing techniques allows us to produce high-performance components with consistent quality and precise dimensions. We understand the importance of certifications and compliance with industry standards like RoHS.

Our experience serving diverse industries, from electronics manufacturers to railway equipment suppliers, provides us with valuable insights into the specific needs of different applications. We can offer tailored solutions, including customized profiles and specialized alloy compositions, to optimize the performance of your products. By choosing us as your supplier, you gain access to high-quality electrical contacts, competitive pricing, and reliable technical support. We strive to build long-term partnerships based on trust and mutual success. Our dedication to innovation and customer satisfaction makes us a preferred choice for businesses seeking reliable electrical contact solutions. We are the manufacturer of electrical contact materials you can rely on.

Key Takeaways:

- Silver Alloy (AGW) powder metallurgy produces superior electrical contacts with excellent conductivity and arc erosion resistance.

- Choosing the right contact material is crucial for both low voltage and high-power applications.

- Powder metallurgy offers precise control over material composition and allows for the creation of complex shapes.

- Weld resistance is a critical safety and performance factor in electrical contacts.

- Selecting a reliable supplier ensures consistent quality and timely delivery of contact rivets and other components.

- Our contact tip solutions are engineered for reliability across diverse applications.

- Different alloys and clad metal technologies offer unique performance characteristics.

- Partnering with a leading manufacturer provides access to expertise, quality, and reliable supply.

For more information on our Silver Alloy Wires, explore our product page. Learn about the precision and quality of our Solid Contact Rivets. Discover our capabilities in producing High-precision and flexible metal stamping.

Post time: Jan-07-2025