Looking for a reliable and versatile material for your next project? This comprehensive guide dives deep into the world of 304 stainless steel wire, exploring its diverse applications, key properties, and why it’s the go-to wire for countless industries. Whether you’re involved in manufacturing, engineering, or even DIY, understanding the capabilities of 304 stainless steel wire mesh and coil forms can unlock significant potential. Read on to discover why this stainless steel 304 variant, including its 304l counterpart, is an indispensable asset.

What Exactly is 304 Stainless Steel Wire and What Makes It Special?

304 stainless steel wire is a member of the austenitic stainless steel family, renowned for its excellent corrosion resistance. This versatile metal is primarily composed of chromium (typically around 18-20%) and nickel (8-10.5%), with a low carbon content. This specific composition grants 304 wire its characteristic strength and resistance to rust and oxidation, making it a choice for a wide range of applications. Its inherent properties make it a widely used stainless option in various industries including food processing, medical, and architectural sectors. The bright, clean finish of stainless steel 304 also contributes to its aesthetic appeal.

The presence of chromium and nickel forms a passive layer on the surface of the wire, which protects it from corrosive environments. This self-healing layer is what gives 304 stainless steel wire its superior corrosion resistance compared to carbon steel. Furthermore, 304 wire exhibits good ductility and formability, making it easy to weld and process into various shapes and forms, including coils and wire mesh. This combination of propertyies explains why it is such a widely used material in manufacturing and engineering.

What are the Key Mechanical Properties of 304 Stainless Steel Wire That Make It So Durable?

The mechanical properties of 304 stainless steel wire are crucial to its widespread utility. It possesses significant tensile strength, meaning it can withstand a considerable amount of pulling force before breaking. This makes it ideal for applications requiring high strength and durability, such as spring wire or fasteners. The ductility of the alloy allows it to be drawn into fine wire diameters without losing its integrity.

Furthermore, 304 stainless steel wire demonstrates excellent toughness, meaning it can absorb energy before fracturing. This is particularly important in applications where the wire may be subjected to impact or stress. While 304 wire is generally non-magnetic in its annealed condition, it can become slightly magnetic after cold working or drawing processing. This isn’t typically a concern for most applications but is a point to consider for highly sensitive electronic uses. Its inherent durable nature makes it a high-quality choice for critical components.

**

Beyond Strength: What Thermal Properties Does 304 Stainless Steel Wire Offer?

Beyond its mechanical prowess, 304 stainless steel wire also exhibits favorable thermal properties. It has a relatively high melting point, making it suitable for applications involving elevated temperatures. While it’s not designed for extremely high-heat environments, its resistance to scaling and oxidation at moderate temperatures is a significant advantage. This makes it a reliable material for components in machinery and equipment that generate heat.

The thermal conductivity of 304 wire, while lower than some other metals like copper, is still sufficient for many applications where heat transfer is a factor. Its ability to withstand temperature fluctuations without significant degradation makes it a dependable choice for various industries. The annealing process, a heat treatment used to soften the metal and relieve internal stresses, further enhances its thermal stability and workability. For components requiring specific electrical conductivity, consider exploring our range of electrical contact tips.

Where Can You Find 304 Stainless Steel Wire Applications Across Various Industries?

The wide range of applications for 304 stainless steel wire spans numerous industries. In the food processing sector, its excellent corrosion resistance and hygienic properties make it ideal for wire mesh conveyors, filters, and food handling equipment. The pharmaceutical industry also relies on 304 wire for similar reasons, where cleanliness and resistance to harsh chemicals are paramount.

In the automotive industry, 304 stainless steel wire is used in components like springs, cables, and fasteners due to its strength and durability. The aerospace sector benefits from its high strength-to-weight ratio in various structural components and safety tie wires. The architectural field utilizes 304 wire for aesthetic purposes in railings, cables, and decorative wire mesh. Even in diy projects, you’ll find 304 stainless steel wire being used for crafting, repairs, and securing items due to its versatile nature. Its wide array of uses underscores its importance as a fundamental material. We also supply reliable contact assemblies for various industrial applications.

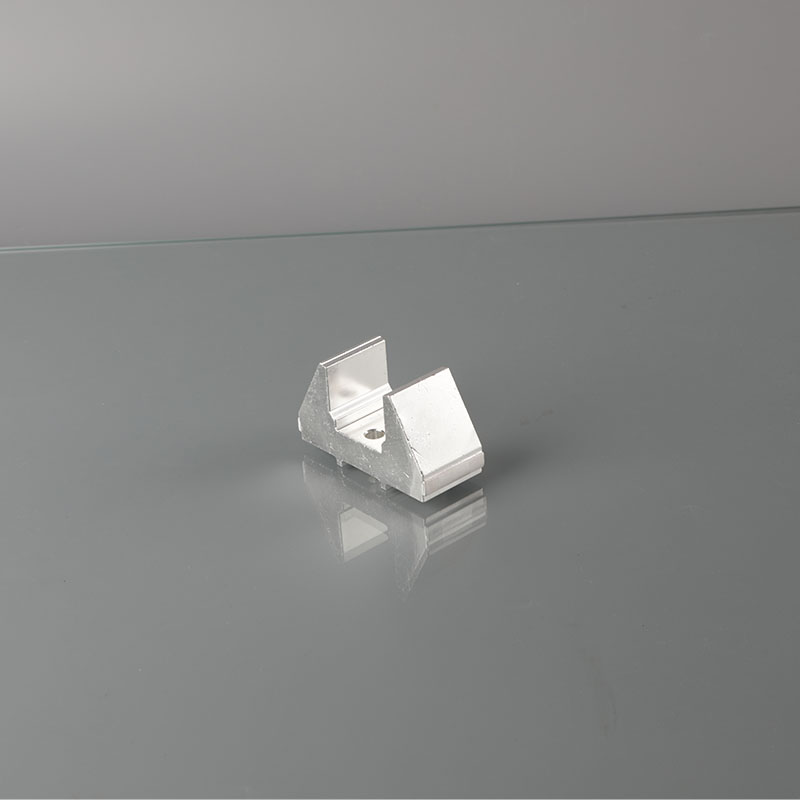

Riveting Assembly

What are the Advantages of Using 304 Stainless Steel Wire Mesh in Different Scenarios?

304 stainless steel wire mesh inherits the beneficial properties of the wire itself, offering several advantages in various applications. Its high corrosion resistance makes it an excellent choice for filtration in harsh environments, such as chemical processing plants or marine applications. The strength of the metal ensures the wire mesh can withstand significant pressure and wear.

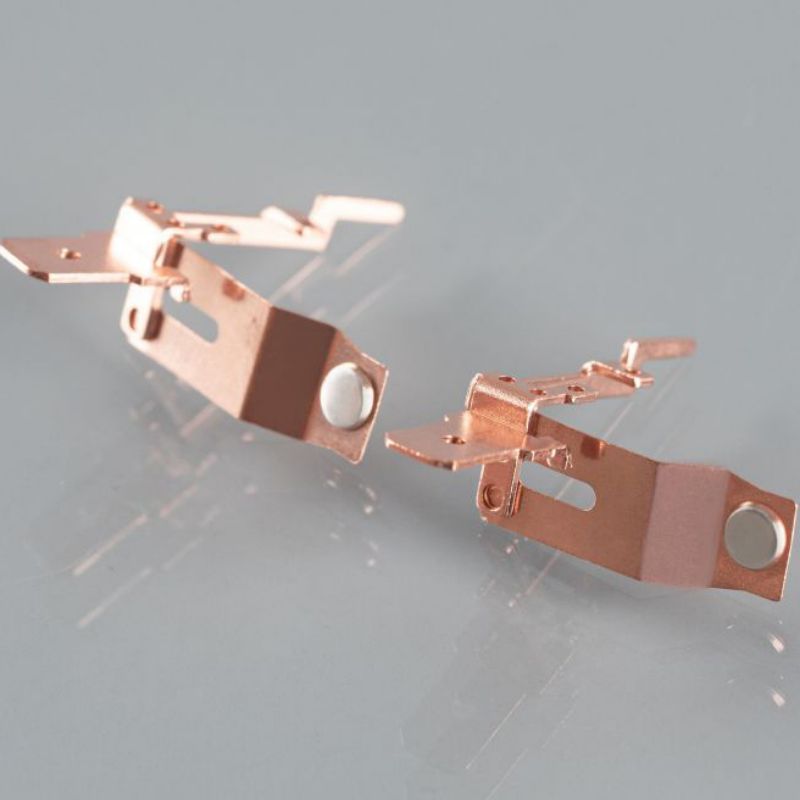

The smooth surface of 304 stainless steel wire mesh is easy to clean and sanitize, making it ideal for food processing and pharmaceutical applications where hygiene is critical. Its durability ensures a long lifespan, reducing the need for frequent replacements. The consistent mesh size and weaving patterns make it a precise and reliable material for screening, sieving, and separation processes. From simple window screens to complex industrial filters, 304 wire mesh offers a robust and dependable solution. Our expertise extends to providing high-quality solid contact rivets for secure assembly.

How Does the Temperature Resistance of 304 Stainless Steel Wire Benefit Specific Uses?

The ability of 304 stainless steel wire to withstand a range of temperatures is a key advantage in many applications. In high-temperature environments, such as ovens or industrial furnaces, components made from 304 wire resist scaling and maintain their structural integrity. This is crucial for safety and longevity in these demanding conditions.

Conversely, 304 stainless steel wire also performs well in low-temperature applications, exhibiting good toughness even in cold environments. This makes it suitable for use in refrigeration equipment or outdoor structures exposed to freezing conditions. The temperature stability of 304 wire ensures consistent performance across a wide temperature spectrum, making it a reliable material for diverse operational environments. This resistance is vital in applications like locomotive contact systems, where temperature variations can be significant.

What’s the Difference Between 304 and 304l Stainless Steel Wire, and When Should You Choose Each?

While both 304 and 304l stainless steel wire share similar properties, the key difference lies in their carbon content. 304l has a lower carbon content compared to standard 304. This seemingly small difference has significant implications for welding applications. The lower carbon content in 304l reduces the risk of carbide precipitation during welding, a phenomenon that can lead to reduced corrosion resistance in the weld area.

Therefore, 304l is often preferred for welding applications, especially when the welded component will be exposed to corrosive environments. Standard 304 is perfectly suitable for applications where welding is minimal or not required, or where post-weld heat treatment can mitigate the risk of carbide precipitation. Both grades offer excellent corrosion resistance, but the choice between them often depends on the specific fabrication methods and the intended service environment. Consider our range of bimetal contact rivet options for applications requiring specific electrical and mechanical properties.

How Can You Ensure You’re Getting High-Quality 304 Stainless Steel Wire That Meets ASTM Standards?

Ensuring the quality of 304 stainless steel wire is paramount for its intended performance and longevity. Reputable suppliers will provide material certifications that confirm the alloy composition meets relevant ASTM standards. These standards outline the specific chemical and mechanical properties that 304 wire must possess.

When sourcing 304 stainless steel wire, look for suppliers with robust quality control processes and certifications like ISO. Requesting samples and conducting thorough inspections can also help verify the quality of the wire. Dimensional accuracy, surface finish, and consistent material properties are key indicators of a high-quality 304. Partnering with a trusted factory specializing in electrical contacts and precision components, like us, guarantees assurance of quality and compliance.

Looking for Specifics? Where Can You Find a Detailed Technical Data Sheet and Specification for 304 Wire?

A detailed technical data sheet and specification for 304 wire are essential for engineers and designers to ensure the material meets the specific requirements of their application. These documents typically provide precise information on the chemical composition, mechanical properties (like tensile strength, yield strength, elongation), thermal properties (thermal conductivity, specific heat), and applicable ASTM standards.

Reputable manufacturers and suppliers will readily provide these technical data sheets upon request. These documents are crucial for making informed decisions about material selection and for ensuring the 304 stainless steel wire is suitable for its intended purpose. You can often find these specification sheets on the supplier’s website or by contacting their sales or technical support team directly. For custom wire needs or specific inquiries, reaching out to the manufacturer is always recommended.

Ready to Get Started? How Can You Get a Quote for Your 304 Stainless Steel Wire Needs?

Ready to incorporate the versatile high-quality 304 stainless steel wire into your next project? Getting a get a quote is the first step. When requesting a quote, be sure to provide specific details about your requirements, including the desired diameter, quantity (kg), form (e.g., coil, straight lengths, wire mesh), and any specific finish or coating requirements.

Providing clear and accurate information will help suppliers provide you with an accurate and competitive quote. Don’t hesitate to ask questions about lead times, payment methods, and shipping options. As a leading factory specializing in electrical contacts, we encourage you to please fill out our contact form or reach out directly to discuss your specific custom metal and CNC Machining Parts needs. We are committed to providing high-quality products and excellent customer service.

Key Takeaways:

- 304 stainless steel wire is a versatile and durable material known for its excellent corrosion resistance.

- Its key mechanical properties include high tensile strength and good ductility, making it suitable for a wide range of applications.

- 304 wire also offers favorable thermal properties, withstanding moderate to high temperatures.

- It’s widely used across various industries, including food processing, automotive, aerospace, and architectural.

- 304l is a low-carbon variant preferred for welding applications due to its reduced risk of carbide precipitation.

- Always ensure you’re sourcing high-quality 304 stainless steel wire that meets relevant ASTM standards.

- Detailed technical data sheets and specifications are crucial for engineers and designers.

- Contact reputable suppliers to get a quote for your specific 304 stainless steel wire requirements.

Post time: Dec-26-2024