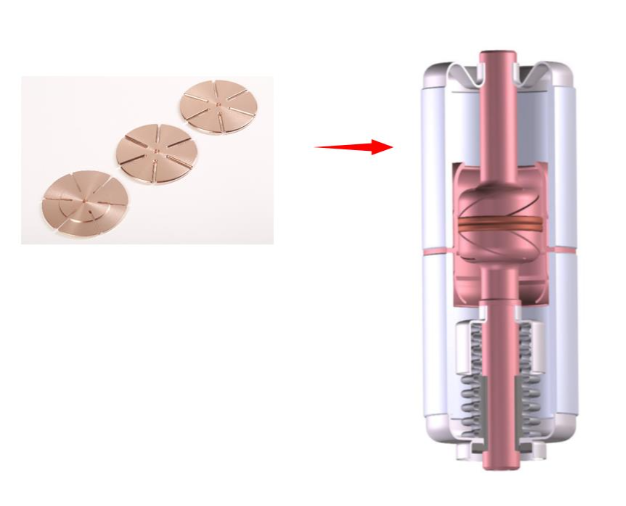

Copper-chromium contact is a kind of electrical contact material commonly used in medium and high-voltage electrical equipment. It has the advantages of strong breaking capacity, arc erosion resistance, and low current interception level. It is widely used in vacuum interrupter chambers, circuit breakers, and contactors.

Its main components are copper Cu and chromium Cr. Common proportions include CuCr2, CuCr25, CuCr30, CuCr35, CuCr40, CuCr45, and CuCr50.

Currently, the methods for preparing CuCr contact materials mainly include powder metallurgy, vacuum infiltration, vacuum casting, and arc melting processes.

- Powder metallurgy is a process in which metal powders or metal oxide powders are mixed in proportion, and then processed into contacts through molding, sintering, extrusion, drawing (rolling), etc.

- Vacuum infiltration refers to a process in which molten metal or other substances are injected into other substances at high temperatures to infiltrate, process, or improve them. During the infiltration process, the molten metal enters the small holes or cracks on the surface of the matrix, diffuses and solidifies in the matrix, and thus forms a solid alloy.

- Vacuum casting is the process in which all copper and chromium are melted into a melt, and then the melt is poured into a water-cooled crucible at one time for cooling, cast into an ingot, and finally processed into contact through subsequent treatments such as extrusion and drawing.

- Arc melting is the process in which the electrode rod is melted layer by layer by a high-temperature arc in an inert gas environment and dripped into a crystallizer, and the crystallizer is rapidly cooled to form an ingot, which is then processed into a contact.

Among them, the contact metallographic structure made by the arc melting process is more compact and uniform, with better-breaking performance and stronger arc erosion resistance. However, due to its high cost, it is generally used in high-end products.

SHZHJ can supply all kinds of silver alloy and copper alloy contacts for low-mid-high voltage devices. Welcome inquiries to info@shzhj.com

Post time: Feb-06-2025