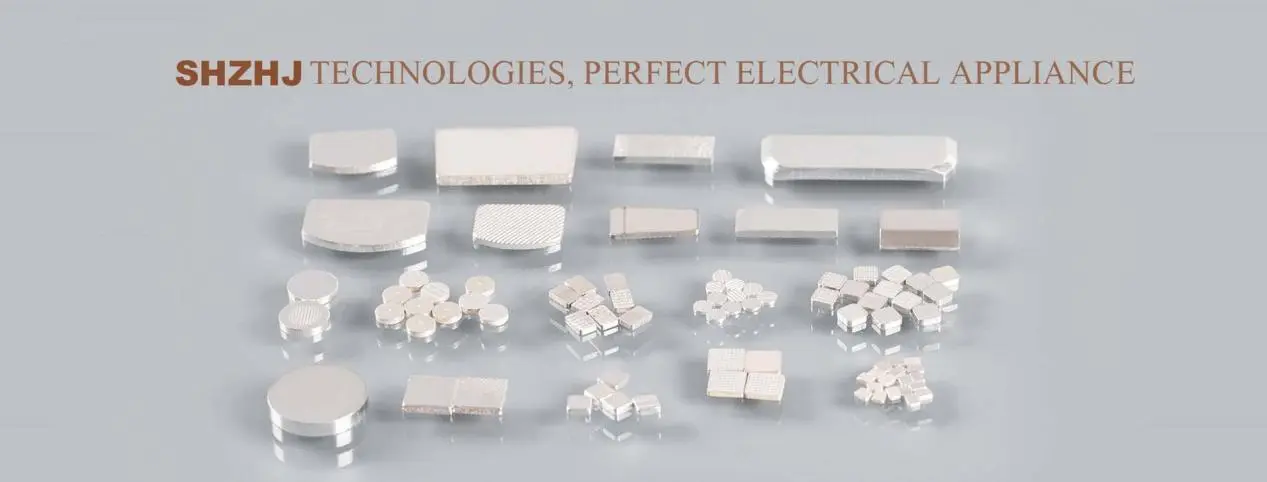

The composition and quality of contact products prepared by powder metallurgy are easier to control than those of other process methods, ensuring consistency of contract performance. The main materials include AgC, AgW, AgWC, etc.

AgW, AgC, and AgWC are all important contact materials in the electrical industry, and each has unique differences, advantages, and application scenarios. Below is a detailed comparison and selection advice on these three materials:

- AgW (silver tungsten) materials

- Composition and structure:

AgW is a composite material of silver (Ag) and tungsten (W). Tungsten has a high melting point, high hardness, and good resistance to arc ablation, while silver provides good electrical and thermal conductivity. This dual-phase structure allows the AgW contact to withstand the high temperature and mechanical shock of the arc in the tungsten phase during operation, while the silver phase ensures the smooth conduction of the current.

2. Advantage:

High resistance to arc ablation: In high voltage, high current switchgear, such as high voltage circuit breakers, when the contact breaks the circuit to produce an arc, tungsten’s high melting point (3410 ℃) can effectively resist the arc ablation and reduce the loss of contact material, thus extending the service life of the contact.

Good electrical conductivity combined with thermal conductivity: silver conductivity and thermal conductivity are very high, to ensure that the conductive current in the contact resistance is small, and can be timely to the heat generated by the work of the contacts to avoid local overheating. For example, AgW contacts can effectively reduce energy loss in industrial electrical equipment that requires frequent switching of large currents.

Stable mechanical properties: the addition of tungsten makes the contacts have high hardness and mechanical strength, which can withstand the mechanical impact of the switching process, and is not easy to be deform, ensuring the contact reliability of the contacts.

3. Applicable scenes:

Mainly used in high-voltage, high-current electrical equipment, such as high-voltage isolation switches, high-voltage load switches, etc. These devices require contacts to work stably under high voltage and high current conditions, with high resistance to arc abrasion and good conductivity and thermal conductivity.

- AgC(silver graphite) materials

- Composition and structure:

AgC is a composite material of silver (Ag) and graphite (C). Graphite has good lubricity and self-lubricating ability, which can reduce friction during the opening and closing process of the contact. Silver is the main conductive phase to ensure the conductivity of the contacts.

2. Advantage:

Excellent abrasion resistance and anti-melt welding resistance: In frequently opening and closing circuits, the lubricating effect of graphite can significantly reduce the wear of the contacts. At the same time, graphite prevents the contacts from fusing due to overheating when the contacts pass high currents in the closed state. For example, in some AC contactors and relays and other frequently operated electrical equipment, AgC contacts can effectively reduce wear and improve the service life of the equipment.

Good arc extinguishing performance: graphite can decompose and produce gases under the action of an electric arc, these gases help to extinguish the electric arc and reduce the abrasion of the electric arc on the contacts.

Stable contact resistance: silver ensures the conductivity of the contacts, making the contact resistance remain relatively stable during the long-term use of the contacts, which is conducive to the stable operation of electrical equipment.

- Applicable scenes:

Applicable to electrical equipment with frequent operation and relatively small current, such as relays, contactors, microswitches and so on. These equipment have higher requirements on the wear resistance, anti-melting and arc extinguishing performance of the contacts, and AgC contacts can well meet these requirements.

III. AgWC (silver tungsten carbide) materials

- Composition and structure:

AgWC is a composite material of silver, tungsten, and tungsten carbide (WC). Tungsten carbide has high hardness, high melting point, and good abrasion resistance. Combined with silver and tungsten, it forms a contact material with excellent comprehensive performance.

2. Advantage:

Excellent wear resistance and arc abrasion resistance: The high hardness and high melting point of tungsten carbide enable it to maintain good shape and performance under frequent opening and closing of contacts and arc action, effectively resisting wear and arc abrasion. In some harsh working environments, such as high dust, and high humidity in the environment of the electrical equipment, AgWC contacts wear resistance and arc abrasion resistance advantage is more obvious.

Good balance of electrical and thermal conductivity: The presence of silver ensures that the contacts have good electrical and thermal conductivity, and can conduct current while dissipating heat in time to maintain the normal operating temperature of the contacts.

High mechanical strength: the addition of tungsten and tungsten carbide makes the contacts have high mechanical strength and can withstand greater mechanical pressure and impact, sand is suitable for some of the contact mechanical properties of the higher equipment requirements.

3. Applicable scenes:

Commonly used in the contact performance requirements of harsh occasions, such as some special industrial environments of high-voltage electrical equipment, heavy-duty motor controllers and so on. These equipments need contact materials with high abrasion resistance, high resistance to arc ablation, good mechanical strength and stable electrical and thermal conductivity.

Post time: Jan-03-2025