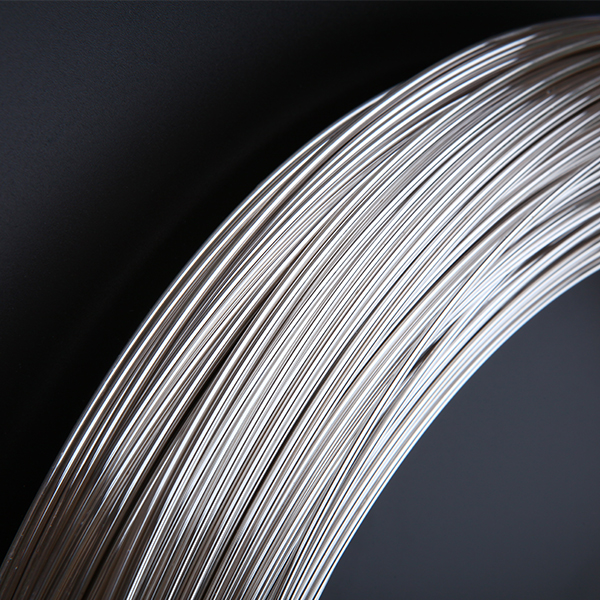

Argentum Alloy Wires

| Applicatio: |

| Contactores, murorum ambitus, thermostatorum, virgas intelligentium, etc |

| Materia: |

| Ag/FAg, AgNi, AgCdO, AgZnO, AgSnO2,AgSnO2In2O3 |

Ag- Fag

1. Microstructure

2. Descriptio Generalis

Argentum et granum argenteum (FAg) altissimas electricas et thermas conductivity, humilem et stabilem contactum resistentiae possident et bonam operabilitatem.Argente resistentia arcui exesa et contactu glutino limitata, vis mechanica humilis est, Ob parvam quantitatem nickel in argento subtili frumenti, resistentia arcui exesa et vi mechanica altior quam argenti.

3. Application Scope

Late adhibentur in machinis currentibus humilibus, ut sunt mensae, timers, permutationes auxiliares pro adjumenta domestica, virgas moderandas, etc.

4. Material Properties

| Ag | Fag | |||

| Apicibus | filis | Apicibus | filis | |

| Ag Content (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Densitas (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Resistentia (pQ • cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| duritia HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Fortitudo distrahentes (MPa) |

| 230-380 |

| 250-380 |

| Prolongatio (%) |

| 2-30 |

| 2-30 |

| Vestibulum processus | Extruding-Rolling | Extrudendo -Drawing | Extruding-Rolling | Extrudendo -Drawing |

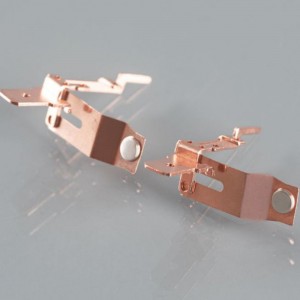

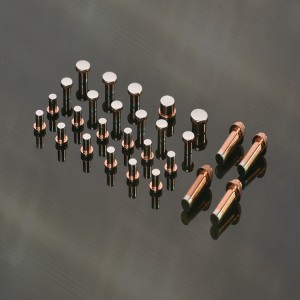

5. Product Genera

AgNi

1. Microstructure

2. Descriptio Generalis

AgNi materiae resistentiam maiorem habent ad exesum arcui et contactum glutino quam Ag vel FAg.Utraque proprietas emendatur cum augendo NI contenta.Omnes AgNi materiae bonam operabilitatem ostendunt et ad subsidia contacta facile contrahunt.Humilis inclinatio ad materiam translationis in applicationibus DC.AgNi materiae sunt materiae environment-protective.

3. Application Scope

AgNi materiae contactum amplis applicationis in humili intentione mutandi machinas inveniunt.Soluntur in mensas, parvas contactores, levia virgas, temperaturas moderatores ac in virgas tutelares (sunt in paribus contactus asymmetricis, verbi gratia, contra AgC, AgZnO orAgSnO2).

4. Material Properties

| filis | AgNi | AgNi | AgNi | Ag Ni | AgN i* | AgNi |

| Ni Content (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Densitas (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| duritia HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Fortitudo distrahentes (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Prolongatio(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Vestibulum processus | Sintering-Extruding | |||||

5. Product Genera

AgCdO

1. Microstructure

2. Descriptio Generalis

AgCdO contactus pertinent ad coetum maxime latissime usorum in campo apparatus electricorum humilium intentionum.Resistentiam convenientem coniungunt contra contactum glutinum cum bono arcu exesa resistentia et satis humilibus resistentia in plenam suam vitam serviendi.Fiunt cum duabus diversis technicis technicis, prae-oxidationibus-sinersing-extrahendis et oxidationibus internis.In utroque casu Cd0 contenta ab 10 ad 20wt% vagari possunt. Sed Cd et Cd0 ancipitia sanitati et ambitus esse censentur.Quam ob rem usus materiae AgCdO in pluribus regionibus interdictum erit.

3. Application Scope

Maxime in omni fere genere humilium intentionum mutandi inventa.Solent usus in microswitches, dispositos, virgas leves, contactores, permutationes ad adjumenta domestica, quaedam genera virgarum tutelarum, ac in quibusdam speciebus ruptorum ambitus.

4. Material Properties

| filis | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| CdO Content (wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Densitas (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| duritia HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Fortitudo distrahentes (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Prolongatio(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Vestibulum processus | Pre-oxidatio-Sintering-Extruding | Internum Oxidation | |||||

5. Product Genera

AgZnO

1. Microstructure

2. Descriptio Generalis

Magna resistentia contra contactum materiae AgZnO designat.Etiam bonam repugnantiam contra arcum exesum ostendunt.Contactus resistentia AgZnO tendit altiorem quam AgCd0.AgZnO produci potest per prae-oxidatio-inserantium - artificiosorum extra, mixtorum-compactentium-sinentium, necnon per oxidationes internas.AgZnO materiae sunt ambitus materiae -protective.

3. Application Scope

Maxime usus est in ambitu praevaricatores, praesertim in ambitu universali praevaricatores.Aliae applicationis regiones sunt virgas tutelares motores, circa fractores et AC per dispositos currentes residuas.

4. Material Properties

| filis | AgZnO | AgZnO |

| ZnO Content (wt.%) | 8±1 | 10±1 |

| Densitas (g/cm*3) | .9.65 | 9.60 |

| Elec.Resistivity (NO • cm) | 2.25 | 2.35 |

| duritia HV | E30 | 85 |

| Fortitudo distrahentes (MPa) | 285-350 | 285-350 |

| Prolongatio(%) | 15-25 | 12-20 |

| Vestibulum processus | Pre-oxidatio -Sintering-Extruding | |

5. Product Genera

AgSnO2

1. Microstructure

2. Descriptio Generalis

AgSnO2/AgSn021n203 sunt materiae contactus electricae eco-amicae.Bonas habent actiones in proprietatibus anti-erosionis et anti-fasciae, et bonas habent res anti-materiae translationis in circuitu commutationis DC.Praecipui processus fabricandi sunt processus oxidationis interni, processus prae-oxidationis, processus metallurgiae pulveris, processus chemici, etc..

3. Application Scope

Late usus est in variis generibus contactorum, mensarum, ruptorum et permutationum, etc.

4. Material Properties

AgSnO2

| filis | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Content (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Densitas (g/cm*3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistentia (pO • cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| duritia HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Fortitudo distrahentes (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Prolongatio(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Vestibulum processus | Pre-oxidatio-Sintering-Extruding | Chemical Coating | Mixtio-Sintering-Extruding | ||

AgSnO2In203

| filis | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Content (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Densitas (g/cm*3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Resistentia (X • cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| duritia HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Fortitudo distrahentes (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Prolongatio(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Vestibulum processus | Pre-oxidatio-Sintering-Extruding | Internum Oxidation | |||

5. Product Genera

AgSnO2In2O3

1. Generalis Descriptio

2. Microstructure

AgSnO2lAgSn021n203 sunt materiae contactus electricae eco-amicae.Bonas habent actiones in proprietatibus anti-erosionis et anti-fasciae, et bonas habent res anti-materiae translationis in circuitu commutationis DC.Praecipui processus fabricandi sunt processus oxidationis interni, processus prae-oxidationis, processus metallurgiae pulveris, processus efficiens chemicus, etc.

3. Application Scope

Late usus est in variis generibus contactorum, mensarum, ruptorum et permutationum, etc.

4. Material Properties

AgSnO2

| filis | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Content (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Densitas (g/cm*3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistentia (p0 • cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| duritia HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Fortitudo distrahentes (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Prolongatio(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Vestibulum processus | Pre-oxidatio-Sintering-Extruding | Chemical Coating | Mixtio-Sintering-Extruding | ||

AgSnO2In203

| filis | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Content (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Densitas (g/cm*3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Resistentia (p0 • cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| duritia HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Fortitudo distrahentes (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Prolongatio(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Vestibulum processus | Pre-oxidatio-Sintering-Extruding | Internum Oxidation | |||