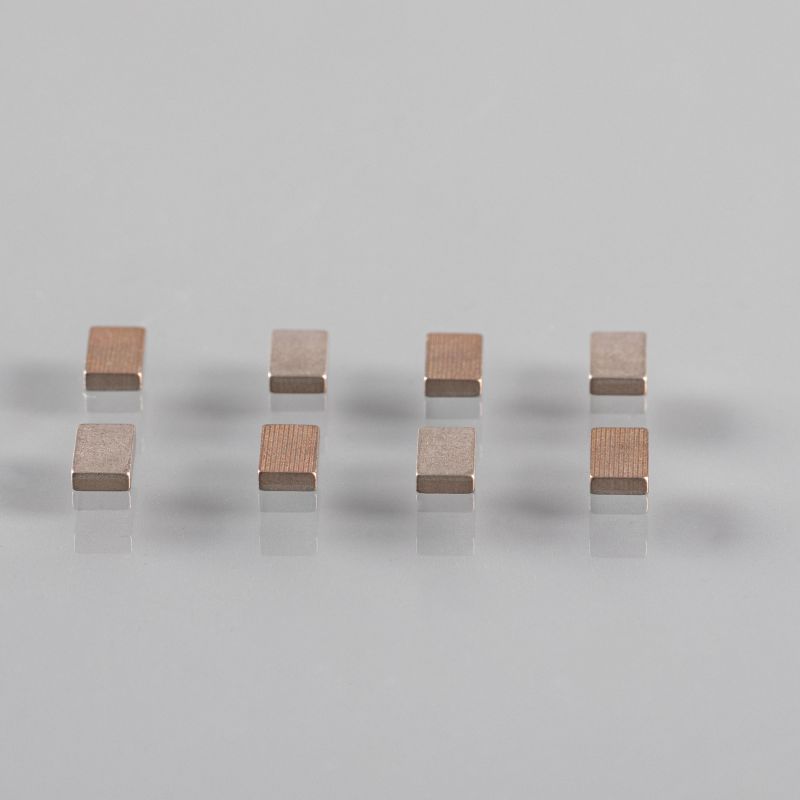

IUNCUS METALLUS Contactus

| Applicatio: |

| Contactores, murorum ambitus, thermostatorum, virgas intelligentium, etc |

| Materia: |

| AgC,AgW,AgWC,AgWCC,AgniC,CuW |

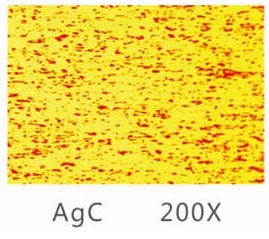

AgC

Microstructure

Communia

AgC materiae contactus ostendent altissimam resistentiam contra contactum glutino et infimum resistentiam.Resistentia contra glutino augetur cum contento graphite augendo.AgC materiae se habent mores lubricantes, cum contactus lapsus usus est.

Applicationem Scope

Maxime in permutationibus tutelae utendum est ut MCBs, MCCBs, virgas tutelares current residuas vel virgas tutelares motores.Applicatio regulariter in par asymmetrica cum AgNi, AgW, AgWC vel Cu.

Materia Properties

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Content(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Densitas (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10 • cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| duritia HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Vestibulum processus | Sintering-Extruding | |||||

Product Genera

AgW

Microstructure

Communia

Contactus ex AgW ostendunt altam resistentiam anti-glutinos et magna resistentia ad exesum arcui propter altum punctum liquescens et altam duritiem W, ipsi quoque bonam electricam et scelerisque conductionem habent.

Applicationem Scope

AgW materiae maxime adhibentur in intentione demissa MCCB et ACB et permutationes tutelae.

Materia Properties

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag Content (wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Densitas (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| duritia HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Vestibulum processus | Infiltration | |||||

Product Genera

AgWC

Microstructure

Communia

Contactus AgWC materias quae componentes refractoriae WC continentes duritiem et resistentiam in usu mechanico habent, humilem inclinationem ad contactum glutino, et resistentiam in servitio contactus relative stabilis habent.Contactus AgWC infiltration metallurgiae pulveris efficiuntur.

Applicationem Scope

Maxime in gravibus officiis mutandi machinis, sicut circa praevaricatores.residua vena ambitus praevaricatores.In multis casibus adhibentur in par asymmetrica cum AgC

Materia Properties

| AgWC | AgWC | AgWC | AgWC | |

| Ag Content (wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Densitas (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| duritia HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Vestibulum processus | Infiltration | |||

Product Genera

AgWCC

Microstructure

Communia

Ob contenti magni AgWCC contactus AgWCC resistentiam contactus habent humilem.Altissimas habent proprietates anti-wedoneae debitae carbide et graphiten tungsten continentem cum puncto alto liquefacto.AgWCC contactus fabricantur per syntering.

Applicationem Scope

Maxime in gravibus officiis mutandi machinis, sicut circa praevaricatores.residua vena ambitus praevaricatores.In multis casibus asymmetricis cum AgNi, AgW vel AgWC adhibentur.

Materia Properties

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag Content (wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Densitas (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0 • cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| duritia HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Vestibulum processus | Mixing-Compacting-Sintering | |||

Product Genera

AgNiC

Microstructure

Communia

Contactus AgNiC commoda contactus agNi et AgC coniungunt.Repugnantiam bonam habent ad exesa electrica et anti-conglutinos possessiones.

Applicationem Scope

AgniC contactus maxime adhibentur in MCCB, ACB.

Materia Properties

| AgNiC | AgNiC | 3AgNiC | |

| Ag Content (wt.%) | 67±1 | 73±1 | 94±1 |

| Densitas (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10 • cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| duritia HV | ≥50 | ≥60 | ≥30 |

| Vestibulum processus | Mixing-Compacting-Sintering | ||

Product Genera

CuW

Microstructure

Communia

CuW materiae contactus praestantem resistentiam habent contra exesum arcus et proprietates anti- glutino usque ad venam altissimam.Contactus cuW in multa varietate figurarum per pulveris metallurgiam (press/sintering vel infiltration) producuntur.Tungsten contentum est 50%-80%.

Applicationem Scope

Contactus cuW maxime adhibentur in media et alta intentione switchgears.Applicationes typicae sunt in alta intentione circa praevaricatores, virgas oneratas, permutator permutat sonum nummulariorum et contactus humilium intentionum arcentium.

Praeterea CuW materiae late uti electrodes, praesertim pro glutino adhibentur.

Materia Properties

| CuW | CuW | CuW | |

| Cu Content (wt.%) | 50±2 | 40±2 | 30±2 |

| Densitas (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| duritia HV | ≥115 | ≥140 | ≥175 |

| Vestibulum processus | Infiltration | ||

Product Genera