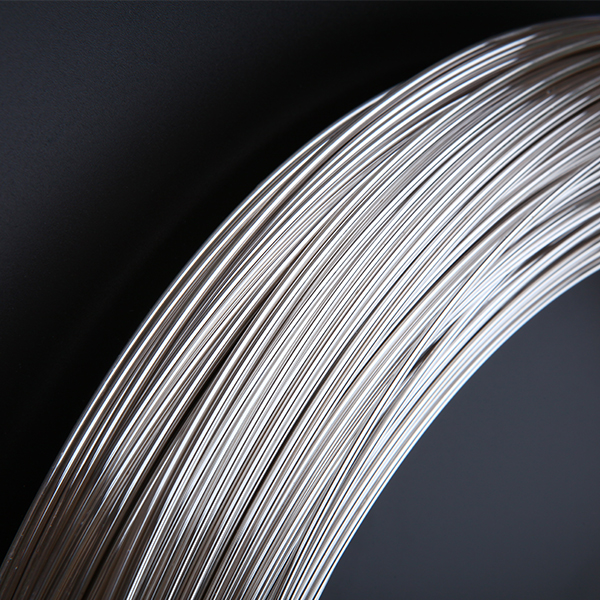

Waya Alloy Silver

| Ngwa: |

| Ndị na-akpọtụrụ, ndị na-agbaji sekit, igwe ọkụ ọkụ, mgba ọkụ nwere ọgụgụ isi, wdg |

| Ihe: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Microstructure

2. Nkọwa zuru oke

Ọlaọcha na ọla ọcha dị mma (FAg) nwere ọkụ eletrik dị elu na ikuku ọkụ, nguzogide kọntaktị dị ala ma kwụsie ike, yana ezigbo ọrụ.N'ihi na ọlaọcha iguzogide arc ozize na kọntaktị ịgbado ọkụ dị oke, n'ibu ike dị ala, N'ihi na obere nke nickel na ezi ọka ọlaọcha, iguzogide arc ozize na n'ibu ike dị elu karịa nke ọlaọcha.

3. Oke ngwa

A na-ejikarị ya na ngwaọrụ dị ugbu a dị ala, dị ka relays, ngụ oge, mgba ọkụ inyeaka maka ngwa ụlọ, njikwa njikwa, wdg.

4. Ngwongwo ihe

| Ag | FAg | |||

| Ndụmọdụ | Waya | Ndụmọdụ | Waya | |

| Ọdịnaya Ag (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Njupụta (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Resistivity (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Isi ike HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Ike tensile (MPa) |

| 230-380 |

| 250-380 |

| Mgbatị (%) |

| 2-30 |

| 2-30 |

| Usoro mmepụta ihe | Na-ebupụ-na-agbagharị | Extruding - ịse | Na-ebupụ-na-agbagharị | Extruding - ịse |

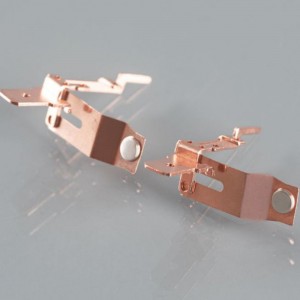

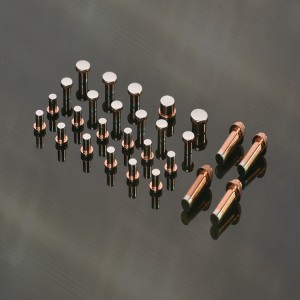

5. Ụdị ngwaahịa

AgNi

1. Microstructure

2. Nkọwa zuru oke

Ngwa AgNi nwere oke nguzogide arc na welding kọntaktị karịa Ag ma ọ bụ FAg.A na-emeziwanye akụrụngwa abụọ a site na ịba ụba ọdịnaya Ni.Ngwa AgNi niile na-egosi arụmọrụ dị mma yana ọ dị mfe ịgbanye kọntaktị nkwado.Ọchịchọ dị ala maka mbufe ihe na ngwa DC.Ngwa AgNi bụ ihe nchekwa gburugburu ebe obibi.

3. Oke ngwa

Ngwa kọntaktị AgNi na-achọta ngwa dị iche iche na ngwaọrụ mgbanwe voltaji dị ala.A na-eji ha na relays, obere kọntaktị, ọkụ ọkụ, ndị na-ahụ maka okpomọkụ yana na mgbanaka nchebe (a na-eji ha na kọntaktị asymmetric, dịka ọmụmaatụ, megide AgC, AgZnO orAgSnO2).

4. Ngwongwo ihe

| Waya | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ọdịnaya Ni (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Njupụta (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Isi ike HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Ike tensile (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Mgbatị(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Usoro mmepụta ihe | Sintering-Extruding | |||||

5. Ụdị ngwaahịa

AgCdO

1. Microstructure

2. Nkọwa zuru oke

Kọntaktị AgCdO so na otu ndị a na-ejikarị eme ihe n'ọhịa nke ngwa eletriki dị ala.Ha na-ejikọta a na-eju afọ iguzogide megide kọntaktị ịgbado ọkụ na ezigbo arc erosion nguzogide na a pụtara ala kọntaktị iguzogide n'elu ya zuru ezu ọrụ ndụ.A na-emepụta ha na usoro abụọ dị iche iche, pre-oxidation-sintering-extruding na esịtidem oxidation.N'okwu abụọ ahụ ọdịnaya Cd0 nwere ike ịdị site na 10 ruo 20wt. Otú ọ dị, Cd na Cd0 na-ewere dị ka ihe ize ndụ nye ahụike na gburugburu ebe obibi.N'ihi nke a, a ga-amachibido iji ihe AgCdO n'ọtụtụ mba.

3. Oke ngwa

A na-ejikarị ya n'ihe fọrọ nke nta ka ọ bụrụ ụdị ngwaọrụ ọ bụla na-agbanwe voltaji dị ala.A na-ejikarị ha eme ihe na microswitches, relays, ọkụ ọkụ, kọntaktị kọntaktị, ihe ọkụ maka ngwa ụlọ, ụfọdụ ụdị mgbanaka nchebe, yana n'ụdị ụfọdụ nke sekit.

4. Ngwongwo ihe

| Waya | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| Ọdịnaya CdO(wt.%) | 10±1 | 13.5 ± 1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Njupụta (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Isi ike HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Ike tensile (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Mgbatị(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Usoro mmepụta ihe | Pre-oxidation-Sintering-Extruding | Oxidation n'ime | |||||

5. Ụdị ngwaahịa

AgZnO

1. Microstructure

2. Nkọwa zuru oke

Nnukwu nguzogide megide ịgbado ọkụ kọntaktị na-egosipụta ihe AgZnO.Ha na-egosipụtakwa nguzogide dị mma megide mbibi arc.Nkwụsị kọntaktị nke AgZnO na-adị elu karịa nke AgCd0.Enwere ike ịmepụta AgZnO site na tupu oxidation-sintering - extruding, ngwakọta-compacting-sintering usoro yana site n'ime oxidation.Ihe AgZnO bụ gburugburu - ihe nchebe.

3. Oke ngwa

A na-ejikarị na sekit breakers, karịsịa na eluigwe na ala sekit breakers.Akụkụ ngwa ndị ọzọ bụ mgbanaka nchekwa moto, ihe mgbaji sekit ugbu a na relays AC.

4. Ngwongwo ihe

| Waya | AgZnO | AgZnO |

| Ọdịnaya ZnO(wt.%) | 8±1 | 10±1 |

| Njupụta (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Isi ike HV | E30 | 85 |

| Ike tensile (MPa) | 285-350 | 285-350 |

| Mgbatị(%) | 15-25 | 12-20 |

| Usoro mmepụta ihe | Pre-oxidation -Sintering-Extruding | |

5. Ụdị ngwaahịa

AgSnO2

1. Microstructure

2. Nkọwa zuru oke

AgSnO2/AgSn021n203 bụ ihe kọntaktị eletrịkị enyi na enyi.Ha nwere arụmọrụ dị mma na mgbochi-erosion na mgbochi ịgbado ọkụ, ma nwee ezigbo ihe na-ebufe ihe onwunwe na sekit mgbanwe DC.Isi n'ichepụta usoro bụ esịtidem ọxịdashọn usoro, tupu oxidation usoro, uzuzu metallurgy usoro, chemical mkpuchi usoro, wdg.

3. Oke ngwa

A na-eji ya n'ụdị dị iche iche nke contactors , relays, sekit breakers na switches, wdg.

4. Ngwongwo ihe

AgSnO2

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Ọdịnaya SnO2 (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Njupụta (g/cm3) | ≥9.90 | ≥9.95 | 9.85 | 9.85 | ≥9.5 |

| Elec.Nguzogide (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Isi ike HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Ike tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Mgbatị(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Usoro mmepụta ihe | Pre-oxidation-Sintering-Extruding | Ihe mkpuchi kemịkalụ | Ịgwakọta-Sintering-Extruding | ||

AgSnO2In203

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ọdịnaya Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Njupụta (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | 9.72 |

| Elec.Nguzogide (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Isi ike HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Ike tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Mgbatị(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Usoro mmepụta ihe | Pre-oxidation-Sintering-Extruding | Oxidation n'ime | |||

5. Ụdị ngwaahịa

AgSnO2In2O3

1. Nkọwa zuru oke

2. Microstructure

AgSnO2lAgSn021n203 bụ ihe kọntaktị eletrịkị enyi na enyi.Ha nwere arụmọrụ dị mma na mgbochi-erosion na mgbochi ịgbado ọkụ, ma nwee ezigbo ihe na-ebufe ihe onwunwe na sekit mgbanwe DC.Isi n'ichepụta usoro bụ esịtidem oxidation usoro, tupu oxidation usoro, uzuzu metallurgy usoro, chemical mkpuchi usoro, wdg.

3. Oke ngwa

A na-eji ya n'ụdị dị iche iche nke contactors , relays, sekit breakers na switches, wdg.

4. Ngwongwo ihe

AgSnO2

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| Ọdịnaya SnO2 (wt.%) | 10 ± 1 | 10 ± 1 | 12±1 | 12±1 | 15 ± 1 |

| Njupụta (g/cm3) | ≥9.90 | ≥9.95 | 9.85 | 9.85 | ≥9.5 |

| Elec.Nguzogide (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Isi ike HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Ike tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Mgbatị(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Usoro mmepụta ihe | Pre-oxidation-Sintering-Extruding | Ihe mkpuchi kemịkalụ | Ịgwakọta-Sintering-Extruding | ||

AgSnO2In203

| Waya | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ọdịnaya Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Njupụta (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | 9.72 |

| Elec.Nguzogide (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Isi ike HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Ike tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Mgbatị(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Usoro mmepụta ihe | Pre-oxidation-Sintering-Extruding | Oxidation n'ime | |||