Kpọtụrụ ndị ntụ ntụ

| Ngwa: |

| Ndị na-akpọtụrụ, ndị na-agbaji sekit, igwe ọkụ ọkụ, mgba ọkụ nwere ọgụgụ isi, wdg |

| Ihe: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

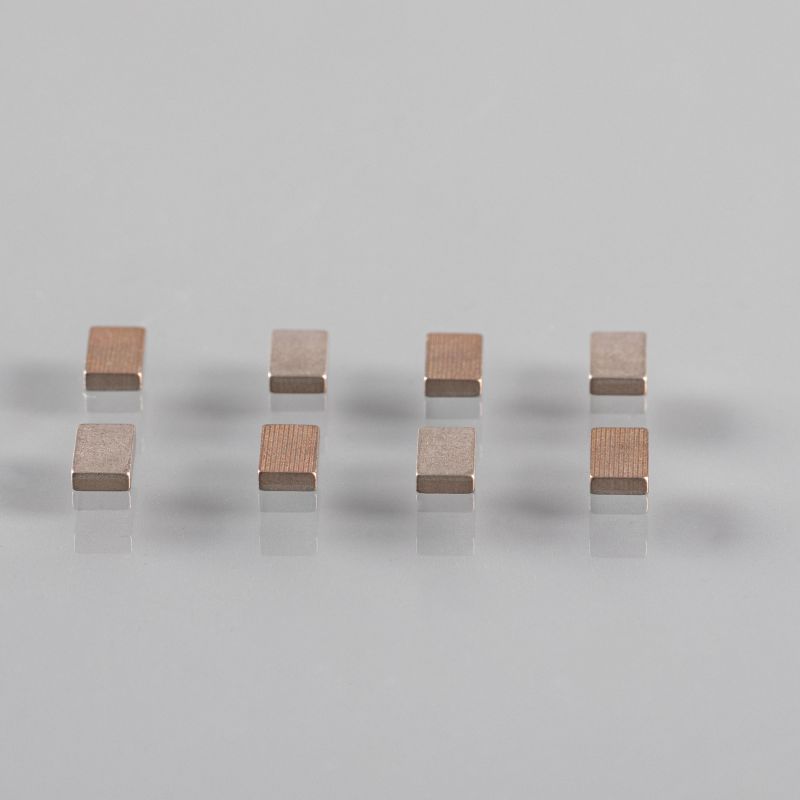

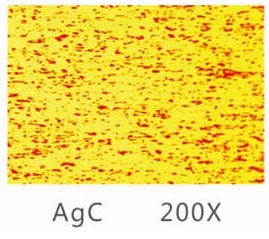

AgC

Microstructure

Nkọwa zuru oke

Ihe kọntaktị AgC na-egosi nguzogide dị elu megide ịgbado ọkụ kọntaktị na obere nguzogide kọntaktị.Nguzogide megide ịgbado ọkụ na-abawanye site na ụbara ọdịnaya graphite.Ihe AgC nwere omume mmanye onwe ya mgbe ejiri ya dị ka kọntaktị na-amị amị.

Oke ngwa

A na-ejikarị ya na mgba ọkụ nchebe dị ka MCBs, MCCBs, mgbanaka nchebe ugbu a, ma ọ bụ mgba ọkụ nchebe moto.Ngwa na-abụkarị egwuregwu asymmetric na AgNi, AgW, AgWC ma ọ bụ Cu.

Njirimara ihe

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C ọdịnaya(wt.%) | 3 ± 0.5 | 4 ± 0.5 | 5 ± 0.5 | 3 ± 0.5 | 3.8 ± 0.5 | 4 ± 0.5 |

| Njupụta (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Isi ike HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Usoro mmepụta ihe | Sintering-Extruding | |||||

Ụdị ngwaahịa

AgW

Microstructure

Nkọwa zuru oke

Kọntaktị emere nke AgW na-egosi oke mgbochi ịgbado ọkụ na oke nguzogide arc n'ihi ebe mgbaze dị elu na ike siri ike nke W, ha nwekwara ezigbo ọkụ eletrik na ọkụ ọkụ.

Oke ngwa

A na-eji ihe AgW eme ihe na obere voltaji MCCB na ACB na mgba ọkụ nchebe.

Njirimara ihe

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag ọdịnaya(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Njupụta (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec. Nguzogide (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Isi ike HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Usoro mmepụta ihe | Ntinyebanye | |||||

Ụdị ngwaahịa

AgWC

Microstructure

Nkọwa zuru oke

Ngwa kọntaktị AgWC nwere akụrụngwa refractory WC nwere ike siri ike na iguzogide igwe eji arụ ọrụ, ọchịchọ dị ala kwupụta ịgbado ọkụ, yana nguzogide kọntaktị kwụsiri ike na ọrụ.A na-emepụta kọntaktị AgWC site na infiltration metallurgy ntụ ntụ.

Oke ngwa

A na-eji ya eme ihe na ngwaọrụ mgbanwe dị arọ, dị ka sekit breakers.ihe fọdụrụ ugbu a sekit breakers.N'ọtụtụ oge, a na-eji ha eme egwuregwu asymmetric na AgC

Njirimara ihe

| AgWC | AgWC | AgWC | AgWC | |

| Ag ọdịnaya(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Njupụta (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Isi ike HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Usoro mmepụta ihe | Ntinyebanye | |||

Ụdị ngwaahịa

AgWCC

Microstructure

Nkọwa zuru oke

N'ihi nnukwu ọdịnaya Ag, kọntaktị AgWCC nwere nguzogide kọntaktị dị ala.Ha nwere ezigbo mgbochi ịgbado ọkụ n'ihi nwere tungsten carbide na graphite nwere nnukwu agbaze.A na-arụpụta kọntaktị AgWCC site na ịmegharị.

Oke ngwa

A na-eji ya eme ihe na ngwaọrụ mgbanwe dị arọ, dị ka sekit breakers.ihe fọdụrụ ugbu a sekit breakers.N'ọtụtụ oge, a na-eji ha eme egwuregwu asymmetric na AgNi, AgW ma ọ bụ AgWC.

Njirimara ihe

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag ọdịnaya(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Njupụta (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Isi ike HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Usoro mmepụta ihe | Ịgwakọta-Compacting-Sintering | |||

Ụdị ngwaahịa

AgNiC

Microstructure

Nkọwa zuru oke

Kọntaktị AgNiC jikọtara uru nke kọntaktị AgNi na AgC.Ha nwere ezigbo nguzogide eletriki na ihe mgbochi ịgbado ọkụ.

Oke ngwa

A na-eji kọntaktị AgNiC eme ihe na MCCB, ACB.

Njirimara ihe

| AgNiC | AgNiC | 3 AgNiC | |

| Ag ọdịnaya(wt.%) | 67±1 | 73±1 | 94±1 |

| Njupụta (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Isi ike HV | ≥50 | ≥60 | ≥30 |

| Usoro mmepụta ihe | Ịgwakọta-Compacting-Sintering | ||

Ụdị ngwaahịa

CuW

Microstructure

Nkọwa zuru oke

Ngwa kọntaktị CuW nwere ezigbo nguzogide megide mbibi arc na ihe mgbochi ịgbado ọkụ ruo oke curret.A na-emepụta kọntaktị CuW n'ụdị dị iche iche site na nchara ntụ ntụ (ịpịpịa / sintering ma ọ bụ infiltration).Ọdịnaya tungsten bụ 50%-80%.

Oke ngwa

A na-ejikarị kọntaktị CuW eme ihe na igwe ọkụ ọkụ na oke ọkụ.Ngwa a na-ahụkarị dị na igwe mgbawa sekit voltaji dị elu, ihe ngbanwe ibu, ndị na-agbanwe ihe na-agbanwe ihe na-agbanwe ọkụ na kọntaktị ọkụ ọkụ dị ala.

Na mgbakwunye, a na-eji ihe CuW eme ihe dị ka electrodes, nke bụ isi maka ịgbado ọkụ.

Njirimara ihe

| CuW | CuW | CuW | |

| Cu ọdịnaya (wt.%) | 50±2 | 40±2 | 30±2 |

| Njupụta (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec. Nguzogide (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Isi ike HV | ≥115 | ≥140 | ≥175 |

| Usoro mmepụta ihe | Ntinyebanye | ||

Ụdị ngwaahịa