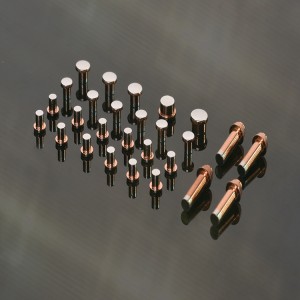

Bimetal Kpọtụrụ Rivet

Njirimara ngwaahịa

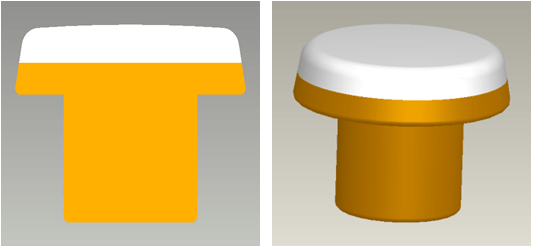

1.Double composite riveting rụọ ọrụ nke ọma na-azọpụta ọla dị oké ọnụ ahịa ma belata ọnụ ahịa

2.melite kọntaktị rivet riveting arụmọrụ.

3.Tinye na-aga n'ihu na mmepụta akpaaka.

Ngwa isi

Ngwa eletriki ụgbọ ala, ngwa ụlọ, ihe eji emegharị, kọntaktị,

Thermostat, ụdị mgba ọkụ niile, ngwa ụgbọ elu, ngụ oge na ngwa eletrọnịkị.

Usoro eruba

Rivet Ime

Na-ewe iwe

Emecha

Nyocha

Ịse ihe

Nkwakọ ngwaahịa

Nkọwa ngwaahịa:Ha nwere arụmọrụ dị mma na mgbochi-erosion na mgbochi ịgbado ọkụ, ma nwee ezigbo ihe na-ebufe ihe onwunwe na sekit mgbanwe DC.Isi n'ichepụta usoro bụ esịtidem ọxịdashọn usoro, tupu oxidation usoro, ntụ ntụ metallurgy usoro, chemical mkpuchi usoro, wdg Silver Tin Oxide Bimetal Kpọtụrụ Rivets nwere ọnụ ala karịa rivets siri ike.

Ntụ:

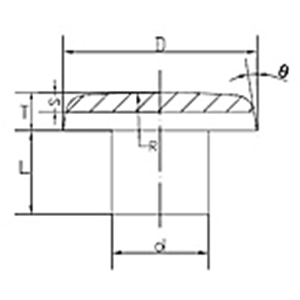

| Ihe | Dayameta isi D (mm) | Ọkpụrụkpụ isi T(mm) | dayameta oyi akwa S(mm) | Dayameta nke ogologo D (mm) | Ogologo ogologo L(mm) | Sphere radium SR (mm) | Oke ebu (▫) |

| nkọwa-cation | 2.5 | 0.6,0.8,1.0 | 0.3 ~ 0.4 | 1.2,1.5 | 1~2 | 4,6 | 9 |

| 3.0 | 0.8,1.0,1.2 | 0.35 ~ 0.50 | 1.50 | 6,8 | |||

| 3.5 | 1.50,2.0 | 1 3 | |||||

| 4.0 | 1.0,1.2,1.5 | 2.0 | 8,10 | ||||

| 4.5 | 2.0,2.5 | ||||||

| 5.0 | 1.0,1.2,1.5,2.0 | 0.40 ~ 0.60 | 2.5 | 10,15 | |||

| 5.5 | 2.5,3.0 | ||||||

| 6.0 | 3.0 | 15,20 | |||||

| 6.5 | 1.2,1.5,2.0 | 0.50 ~ 0.70 | 3.0,3.5 | ||||

| 7.0 | 3.5 | 20,25 | |||||

| 8.0 | 4.0 | ||||||

| isi na shank coaxiality | ±0.1 | ±0.05 | S≤0.4+0.6 S>0.4-0.06 | -0.02,-0.1 | +0,15 | ±0.2R | ±2 |