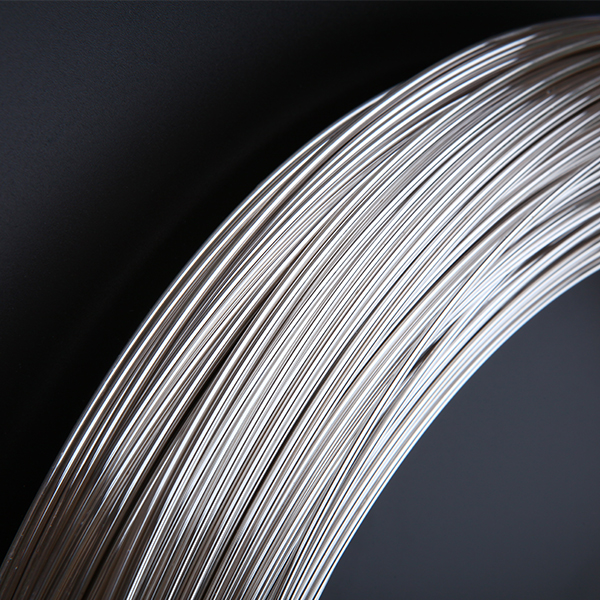

Nyiaj Alloy Hlau

| Daim ntawv thov: |

| Contactors, Circuit Court breakers, thermostats, ntse keyboards, thiab lwm yam |

| Khoom siv: |

| AgNi,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Microstructure

2. Cov lus piav qhia dav dav

Nyiaj thiab nplua nplej nyiaj (FAg) muaj hluav taws xob thiab thermal conductivity, qis thiab ruaj khov tiv thaiv, thiab ua haujlwm zoo.Rau cov nyiaj tsis kam mus rau arc yaig thiab kev sib cuag vuam yog txwv, txhua yam muaj zog tsis tshua muaj, Vim yog cov nyiaj npib tsib xee me me hauv cov nyiaj zoo, tsis kam mus rau arc yaig thiab lub zog txhua yam yog siab dua li cov nyiaj.

3. Daim ntawv thov Scope

Siv dav hauv cov khoom siv qis tam sim no, xws li relays, timers, auxiliary keyboards rau cov khoom siv hauv tsev, tswj cov keyboards, thiab lwm yam.

4. Cov khoom siv

| Ag | FAg | |||

| Tswv yim | Hlau | Tswv yim | Hlau | |

| Ag Cov ntsiab lus (wt.%) | ≥99.95 | ≥99.95 | 99.85 ib | 99.85 ib |

| Qhov ceev (g / cm3) | ≥10.48 | ≥10.48 | ≥10.40 Nws | ≥10.40 Nws |

| Elec.Kev tiv thaiv (pQ•cnn) | ≤ 2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Hardness HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Tensile zog (MPa) |

| 230-380 : kuv |

| 250-380 : kuv |

| Elongation (%) |

| 2-30 |

| 2-30 |

| Cov txheej txheem tsim khoom | Extruding-Rolling | Extruding - Kos duab | Extruding-Rolling | Extruding - Kos duab |

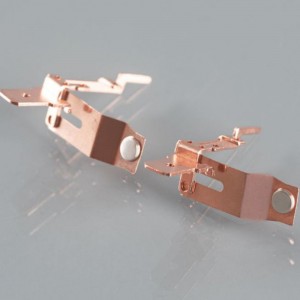

5. Hom khoom

AgNi

1. Microstructure

2. Cov lus piav qhia dav dav

AgNi cov ntaub ntawv muaj kev tiv thaiv ntau dua rau arc yaig thiab tiv tauj vuam dua Ag lossis FAg.Ob qho khoom tau txhim kho nrog nce Ni cov ntsiab lus.Tag nrho cov ntaub ntawv AgNi qhia tau hais tias ua haujlwm tau zoo thiab yooj yim rau kev sib cuag nrog kev txhawb nqa.Tsis tshua muaj siab rau kev hloov khoom siv hauv DC daim ntawv thov.AgNi cov ntaub ntawv yog cov ntaub ntawv tiv thaiv ib puag ncig.

3. Daim ntawv thov Scope

AgNi tiv tauj cov ntaub ntawv pom ntau yam kev thov hauv cov khoom siv hluav taws xob tsawg.Lawv yog siv nyob rau hauv relays, contactors me me, lub teeb keyboards, kub tswj raws li zoo raws li nyob rau hauv kev tiv thaiv keyboards (lawv yog siv nyob rau hauv asymmetric sib cuag khub, piv txwv li, tiv thaivAgC, AgZnO los yogAgSnO2 cov ntaub ntawv).

4. Cov khoom siv

| Hlau | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Cov ntsiab lus (wt.%) | 10 ± 1 | 12 ± 1 | 15 ± 1 | 15 ± 1 | 20 ± 1 | 30 ± 1 |

| Qhov ceev (g / cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 Nws | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤ 1.95 | ≤ 2.05 | ≤ 2.05 | ≤ 2.10 | ≤ 2.15 | ≤ 2.50 |

| Hardness HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Tensile zog (MPa) | 240-450 : kuv | 240-450 : kuv | 250-360 : kuv | 280-460 : kuv | 260-380 : kuv | 260-380 : kuv |

| Elongation (%) | 5-30 | 5-30 | 5-30 | 5–28 | 2-28 | 2-25 |

| Cov txheej txheem tsim khoom | Sintering-Extruding | |||||

5. Hom khoom

AgCdO

1. Microstructure

2. Cov lus piav qhia dav dav

AgCdO cov neeg sib cuag yog cov pab pawg ntawm cov neeg siv ntau tshaj plaws ntawm cov khoom siv hluav taws xob tsawg.Lawv muab cov kev txaus siab tiv thaiv kev tiv thaiv kev sib cuag nrog cov arc yaig zoo tiv thaiv thiab kev tiv thaiv tsis tshua muaj kev sib cuag ntawm nws lub neej ua haujlwm tiav.Lawv tau tsim nrog ob txoj kev sib txawv, ua ntej oxidation-sintering-extruding thiab oxidation sab hauv.Hauv ob qho tib si Cd0 cov ntsiab lus yuav muaj li ntawm 10 txog 20wt.% Txawm li cas los xij, Cd thiab Cd0 raug suav hais tias ua rau muaj kev phom sij rau kev noj qab haus huv thiab ib puag ncig.Vim li no, kev siv cov ntaub ntawv AgCdO yuav raug txwv hauv ntau lub tebchaws.

3. Daim ntawv thov Scope

Feem ntau yog siv nyob rau hauv yuav luag txhua yam ntawm cov tsis tshua muaj voltage switching li.Lawv feem ntau yog siv rau hauv microswitches, relays, lub teeb keyboards, contactors, keyboards rau cov khoom siv hauv tsev, qee hom kev tiv thaiv keyboards, nrog rau qee yam ntawm Circuit Court breakers.

4. Cov khoom siv

| Hlau | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd 0 | AgCdO |

| CdO Cov ntsiab lus (wt.%) | 10 ± 1 | 13.5 ± 1 | 15 ± 1 | 10 ± 1 | 12 ± 1 | 15 ± 1 | 17 ± 1 |

| Qhov ceev (g / cm3) | ≥10.05 Nws | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 Nws | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10 •cm) | ≤ 2.25 | ≤ 2.35 | ≤ 2.40 | ≤ 2.10 | ≤ 2.15 | ≤ 2.25 | ≤ 2.40 |

| Hardness HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Tensile zog (MPa) | 260-350 : kuv | 260-380 : kuv | 260-380 : kuv | 260-350 : kuv | 260-380 : kuv | 260-380 : kuv | 260-400 Nws |

| Elongation (%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | Sab hauv Oxidation | |||||

5. Hom khoom

AgZnO

1. Microstructure

2. Cov lus piav qhia dav dav

Kev tiv thaiv siab tiv thaiv kev sib cuag welding characterizes AgZnO cov ntaub ntawv.Lawv kuj qhia tau zoo tiv thaiv arc yaig.Kev tiv thaiv ntawm AgZnO zoo li siab dua li ntawm AgCd0.AgZnO tuaj yeem tsim los ntawm kev ua ntej oxidation-sintering -extruding, sib xyaw-compacting-sintering cov txheej txheem nrog rau kev oxidation sab hauv.AgZnO cov ntaub ntawv yog ib puag ncig-cov ntaub ntawv tiv thaiv.

3. Daim ntawv thov Scope

Feem ntau yog siv hauv Circuit Court breakers, tshwj xeeb tshaj yog nyob rau hauv universal circuit breakers.Lwm daim ntawv thov yog lub cev muaj zog tiv thaiv keyboards, seem tam sim no Circuit Court breakers thiab AC relays.

4. Cov khoom siv

| Hlau | AgZnO | AgZnO |

| ZnO Cov ntsiab lus (wt.%) | 8 ± 1 | 10 ± 1 |

| Qhov ceev (g / cm3) | 9.65 Nws | 9.60 ib |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 Nws |

| Hardness HV | E30 | 85 |

| Tensile zog (MPa) | 285-350 : kuv | 285-350 : kuv |

| Elongation (%) | 15-25 | 12-20 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | |

5. Hom khoom

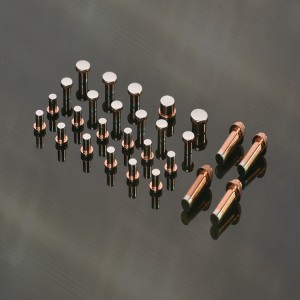

AgSnO2

1. Microstructure

2. Cov lus piav qhia dav dav

AgSnO2 / AgSn021n203 yog cov khoom siv hluav taws xob tiv tauj hauv eco.Lawv muaj kev ua tau zoo hauv kev tiv thaiv kev yaig thiab kev tiv thaiv vuam, thiab muaj cov khoom zoo los tiv thaiv cov khoom siv hauv DC switching circuit.Cov txheej txheem tsim khoom tseem ceeb yog txheej txheem oxidation sab hauv, txheej txheem ua ntej oxidation, hmoov metallurgy txheej txheem, txheej txheej txheej txheej tshuaj, thiab lwm yam..

3. Daim ntawv thov Scope

Siv dav hauv ntau hom contactors, relays, circuit breakers thiab keyboards, thiab lwm yam.

4. Cov khoom siv

AgSnO2

| Hlau | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Cov ntsiab lus (wt.%) | 10 ± 1 | 10 ± 1 | 12 ± 1 | 12 ± 1 | 15 ± 1 |

| Qhov ceev (g / cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Kev tiv thaiv (pO•cm) | ≤ 2.15 | ≤ 2.30 | ≤ 2.30 | ≤ 2.30 | ≤ 2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile zog (MPa) | 295-350 : kuv | 290-385 : kuv | 230-350 Nws | 230-285 : kuv | 250-330 Nws |

| Elongation (%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | Tshuaj Txheej | Mixing-Sintering-Extruding | ||

AgSnO2In203

| Hlau | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Cov ntsiab lus (wt.%) | 90 ± 1 | 88 ± 1 | 92 ± 1 | 88 ± 1 | 85.5 ± 1 |

| Qhov ceev (g / cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kev tiv thaiv (10•cm) | ≤ 2.38 | ≤ 2.45 | ≤ 2.25 | ≤ 2.35 | ≤ 2.55 |

| Hardness HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile zog (MPa) | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv |

| Elongation (%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | Sab hauv Oxidation | |||

5. Hom khoom

AgSnO2In2O3

1. Cov lus piav qhia dav dav

2. Microstructure

AgSnO2lAgSn021n203 yog cov khoom siv hluav taws xob tiv tauj hauv eco.Lawv muaj kev ua tau zoo hauv kev tiv thaiv kev yaig thiab kev tiv thaiv vuam, thiab muaj cov khoom zoo los tiv thaiv cov khoom siv hauv DC switching circuit.Cov txheej txheem tsim khoom tseem ceeb yog txheej txheem oxidation sab hauv, txheej txheem ua ntej oxidation, hmoov metallurgy txheej txheem, txheej txheej txheej txheej tshuaj, thiab lwm yam.

3. Daim ntawv thov Scope

Siv dav hauv ntau hom contactors, relays, circuit breakers thiab keyboards, thiab lwm yam.

4. Cov khoom siv

AgSnO2

| Hlau | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Cov ntsiab lus (wt.%) | 10 ± 1 | 10 ± 1 | 12 ± 1 | 12 ± 1 | 15 ± 1 |

| Qhov ceev (g / cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Kev tiv thaiv (p0•cm) | ≤ 2.15 | ≤ 2.30 | ≤ 2.30 | ≤ 2.30 | ≤ 2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Tensile zog (MPa) | 295-350 : kuv | 290-385 : kuv | 230-350 Nws | 230-285 : kuv | 250-330 Nws |

| Elongation (%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | Tshuaj Txheej | Mixing-Sintering-Extruding | ||

AgSnO2In203

| Hlau | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Ag Cov ntsiab lus (wt.%) | 90 ± 1 | 88 ± 1 | 92 ± 1 | 88 ± 1 | 85.5 ± 1 |

| Qhov ceev (g / cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Kev tiv thaiv (p0•cm) | ≤ 2.38 | ≤ 2.45 | ≤ 2.25 | ≤ 2.35 | ≤ 2.55 |

| Hardness HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Tensile zog (MPa) | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv | 320-450 : kuv |

| Elongation (%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Cov txheej txheem tsim khoom | Pre-oxidation-Sintering-Extruding | Sab hauv Oxidation | |||