POWDER METAL CHAW UA HAUJ LWM

| Daim ntawv thov: |

| Contactors, Circuit Court breakers, thermostats, ntse keyboards, thiab lwm yam |

| Khoom siv: |

| AgC, AgW, AgWC, AgWCC, AgNiC, CuW |

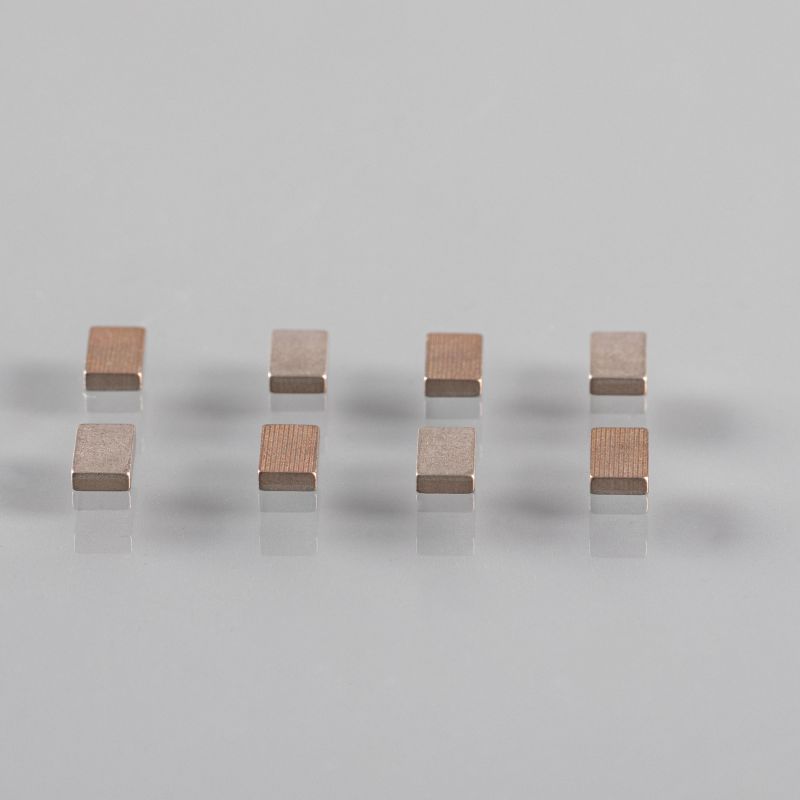

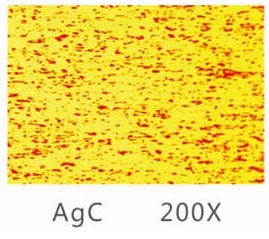

AgC

Microstructure

Kev piav qhia dav dav

AgC cov ntaub ntawv tiv tauj qhia tau hais tias muaj kev tiv thaiv siab heev tiv thaiv kev sib cuag vuam thiab kev tiv thaiv qis.Tsis kam tiv thaiv vuam nce nrog nce graphite cov ntsiab lus.AgC cov ntaub ntawv muaj tus cwj pwm lubricating tus kheej thaum siv los ua zawv zawg sib cuag.

Daim Ntawv Thov Scope

Feem ntau yog siv los tiv thaiv cov keyboards xws li MCBs, MCCBs, residual tam sim no tiv thaiv keyboards, los yog lub cev muaj zog tiv thaiv keyboards.Daim ntawv thov feem ntau yog asymmetric match nrog AgNi, AgW, AgWC lossis Cu.

Khoom Khoom

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C Cov ntsiab lus (wt.%) | 3 ± 0.5 | 4 ± 0.5 | 5 ± 0.5 | 3 ± 0.5 | 3.8 ± 0.5 | 4 ± 0.5 |

| Qhov ceev (g / cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥ 9.00 Nws | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤ 2.10 | ≤ 2.20 | ≤ 2.30 | ≤ 2.10 | ≤ 2.20 | ≤ 2.20 |

| Hardness HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Cov txheej txheem tsim khoom | Sintering-Extruding | |||||

Yam khoom

AgW

Microstructure

Kev piav qhia dav dav

Cov kev sib cuag ua los ntawm AgW qhia tau hais tias muaj kev tiv thaiv kev vuam zoo thiab kev ua haujlwm siab rau arc yaig vim qhov siab melting point thiab siab hardness ntawm W, lawv kuj muaj hluav taws xob zoo thiab thermal conductivity.

Daim Ntawv Thov Scope

AgW cov ntaub ntawv yog tsuas yog siv nyob rau hauv tsawg voltage MCCB thiab ACB thiab tiv thaiv keyboards.

Khoom Khoom

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag Cov ntsiab lus (wt.%) | 50 ± 2 | 45 ± 2 | 40 ± 2 | 35 ± 2 | 30 ± 2 | 25 ± 2 |

| Qhov ceev (g / cm3) | ≥13.15 Nws | ≥13.55 Nws | ≥ 14.00 Nws | ≥14.50 Nws | ≥14.90 | ≥15.40 Nws |

| EIec.Resistivity (1.10 •cm) | ≤ 3.00 | ≤ 3.20 | ≤ 3.40 | ≤ 3.60 | ≤ 3.80 | ≤4.20 |

| Hardness HV | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Cov txheej txheem tsim khoom | Infiltration | |||||

Yam khoom

AgWC

Microstructure

Kev piav qhia dav dav

AgWC cov ntaub ntawv tiv tauj uas muaj cov khoom siv refractory WC muaj qhov tawv tawv thiab ua haujlwm rau cov khoom siv kho tshuab, tsis tshua muaj siab rau kev sib cuag vuam, thiab kev tiv thaiv kev tiv thaiv zoo hauv kev pabcuam.AgWC tiv tauj yog tsim los ntawm hmoov metallurgy infiltration.

Daim Ntawv Thov Scope

Feem ntau yog siv nyob rau hauv hnyav-duty switching li, xws li Circuit Court breakers.residual tam sim no Circuit Court breakers.Feem ntau lawv tau siv hauv asymmetric match nrog AgC

Khoom Khoom

| AgWC | AgWC | AgWC | AgWC | |

| Ag Cov ntsiab lus (wt.%) | 65 ± 2 | 60 ± 2 | 50 ± 2 | 35 ± 2 |

| Qhov ceev (g / cm3) | ≥11.50 Nws | ≥11.80 Nws | ≥12.20 Nws | ≥ 13.00 Nws |

| Elec.Resistivity (1.10 •cm) | ≤ 3.30 | .A.50 | 4.50 Nws | 5.20 ib |

| Hardness HV | ≥100 | ≥125 | ≥135 | ≥155 |

| Cov txheej txheem tsim khoom | Infiltration | |||

Yam khoom

AgWCC

Microstructure

Kev piav qhia dav dav

Vim muaj Ag cov ntsiab lus siab, AgWCC cov neeg sib cuag muaj kev tiv thaiv qis.Lawv muaj kev tiv thaiv zoo heev vim muaj tungsten carbide thiab graphite nrog siab melting point.AgWCC tiv tauj yog tsim los ntawm sintering.

Daim Ntawv Thov Scope

Feem ntau yog siv nyob rau hauv hnyav-duty switching li, xws li Circuit Court breakers.residual tam sim no Circuit Court breakers.Feem ntau lawv tau siv hauv kev sib tw asymmetric nrog AgNi, AgW lossis AgWC.

Khoom Khoom

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Ag Cov ntsiab lus (wt.%) | 85 ± 1 | 75 ± 1 | 79 ± 1 | 74.5 ± 1 |

| Qhov ceev (g / cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Elec.Resistivity (u0•cnn) | ≤ 3.40 | ≤ 3.40 | ≤ 3.80 | ≤ 3.45 |

| Hardness HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Cov txheej txheem tsim khoom | Mixing-Compacting-Sintering | |||

Yam khoom

AgNiC

Microstructure

Kev piav qhia dav dav

AgNiC cov neeg sib txuas ua ke qhov zoo ntawm AgNi thiab AgC hu.Lawv muaj kev tiv thaiv zoo rau hluav taws xob yaig thiab tiv thaiv vuam khoom.

Daim Ntawv Thov Scope

AgNiC cov neeg siv feem ntau yog siv hauv MCCB, ACB.

Khoom Khoom

| AgNiC | AgNiC | 3 AgNiC | |

| Ag Cov ntsiab lus (wt.%) | 67 ± 1 | 73 ± 1 | 94 ± 1 |

| Qhov ceev (g / cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤ 4.50 | ≤ 3.50 | ≤ 3.50 |

| Hardness HV | ≥50 | ≥60 | ≥30 |

| Cov txheej txheem tsim khoom | Mixing-Compacting-Sintering | ||

Yam khoom

CuW

Microstructure

Kev piav qhia dav dav

CuW cov ntaub ntawv tiv tauj tau zoo heev resistsnce tiv thaiv arc yaig thiab los tiv thaiv vuam zog mus txog rau high curret.CuW tiv tauj yog tsim nyob rau hauv ntau yam duab los ntawm cov hmoov metallurgy (nias / sintering los yog infiltration).Cov ntsiab lus tungsten yog 50% -80%.

Daim Ntawv Thov Scope

CuW tiv tauj yog siv nyob rau hauv nruab nrab thiab siab voltage switchgears.Cov ntawv thov yog nyob rau hauv high voltage circuit breakers, load switches, transformer switches kais changers thiab low voltage arcing contacts.

Tsis tas li ntawd, CuW cov ntaub ntawv yog dav siv los ua electrodes, feem ntau rau vuam.

Khoom Khoom

| CuW | CuW | CuW | |

| Cov ntsiab lus Cu (wt.%) | 50 ± 2 | 40 ± 2 | 30 ± 2 |

| Qhov ceev (g / cm3) | ≥11.85 Nws | ≥12.75 | ≥13.80 Nws |

| EIec.Resistivity (p0 cm) | ≤ 3.20 | ≤ 3.70 | ≤ 4.10 |

| Hardness HV | ≥115 | ≥140 | ≥175 |

| Cov txheej txheem tsim khoom | Infiltration | ||

Yam khoom