High-precision thiab saj zawg zog hlau stamping Hoobkas

Stamping Rhiav

SHZHJ muaj kev ywj pheej pwm R & D department thiab pab pawg kws tshaj lij engineers.SHZHJ zoo tsim los ua ib qho ntawm cov khoom zoo tshaj plaws hlau stamping lwm tus neeg.

Pwm Studio

Peb cov neeg ua haujlwm paub txog yuav ua haujlwm nrog koj ntawm txhua yam ntawm cov hlau stamping.Los ntawm kev tsim, kev tsim qauv, FAI, PPAP, cov khoom ntim qis rau nruab nrab thiab cov ntim siab, peb yuav tsim cov khoom raws li koj qhov yuav tsum tau ua.

Khoom

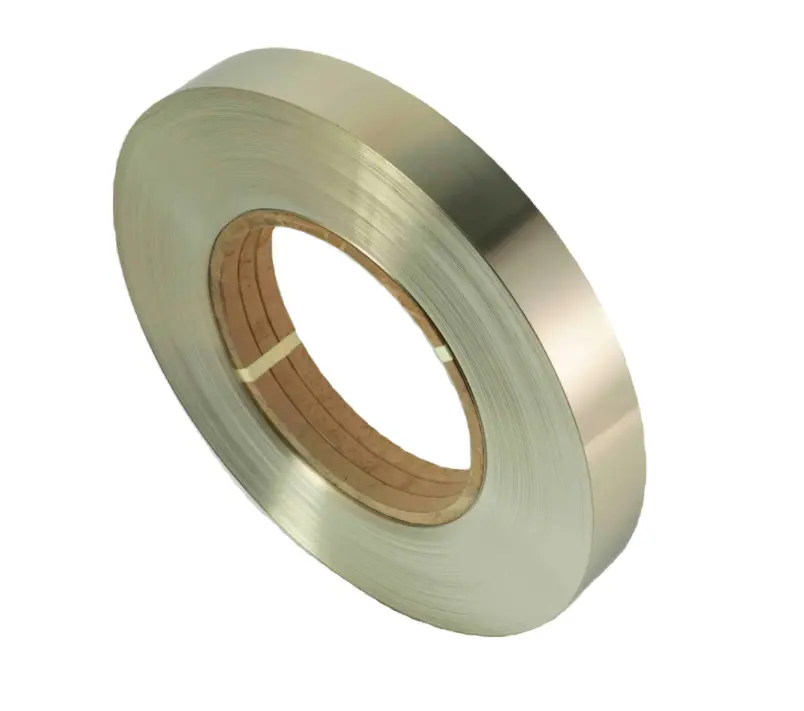

Cov khoom siv raw

SHZHJ siv cov khoom sib txawv los tsim ntau yam khoom zoo raws li qhov yuav tsum tau muaj ntawm kev lag luam sib txawv.Simple strip thiab clad strip stamping muaj. Cov khoom thickness ntau yog 5μm rau 5mm.

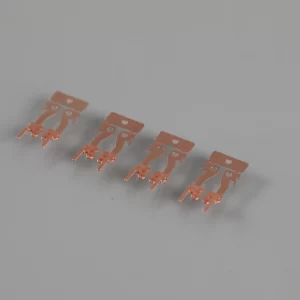

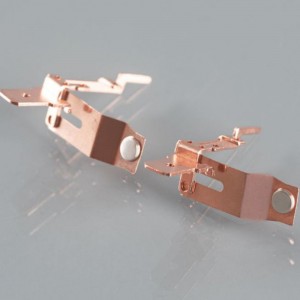

- Tooj

- Tooj liab

- Beryllium tooj liab

- Dawb tooj liab

- Aluminium

- Hlau

- Ntshiab npib tsib xee

- Pre-nickel lossis pre-tin plated cov ntaub ntawv

- Cov kev cai tshwj xeeb rau cov neeg siv khoom

PRECISION METAL STAMPING CAPABILITIES

Progressive Tuag Stamping nrog:

Hauv Tuag Tapping thiab Threaded Inserts

Nyob rau hauv Die Assembly

Hauv Tuag Yob txoj kev nrog Dovetail Interlocked

Progressive Deep Drawing

Hloov Sib Sib Tham

Hloov Stamping / Forming ntawm Extruded & Pre-Machined Tube

Reel rau Reel Stamping

SHZHJ cov txheej txheem stamping siv sab saum toj-ntawm-tus-kab precision hlau stamping tshuab (robotic, phau ntawv lossis cov kab nce qib), peb cov xovxwm muaj li ntawm 45 txog 400 tons, CNC khoom siv nrog tshwj xeeb universal units, jigs thiab fixtures los tsim kev cai. Hlau Stamping.Txhua yam ntawm cov duab tuaj yeem raug punched, xuas nrig ntaus, tsim, stenciled, kos thiab extruded.

Cov kev pabcuam no tau txais kev txhawb nqa los ntawm kev muaj peev xwm ua haujlwm thib ob, suav nrog kev sib dhos tshuab, riveting, tapping thiab vuam, deburring, degreasing thiab ntau yam kev xaiv ntim.

Vim li cas thiaj xaiv SHZHJ - stamping ntau lawm

♦ Raws li qhov yuav tsum tau kos duab, sim cov khoom muaj pes tsawg leeg thiab cov khoom siv hlau ua kom ntseeg tau tias cov khoom ua tau raws li qhov yuav tsum tau ua.

♦ Raws li qhov kev nug, peb ntsuas 2D thiab 3D cov ntaub ntawv uas muaj cov ntaub ntawv tseem ceeb xws li cov ntaub ntawv, kev kam rau siab, qhov loj me thiab kev ua tiav.Nyob ntawm cov khoom, lub tuam txhab pwm ua cov txheej txheem sib txawv rau kev tsim khoom.

♦ Cov txheej txheem hlau stamping pib nrog ib daim hlau tiaj tus lossis lub raj hlau.Nws tau muab tso rau hauv lub tshuab stamping tsim nyog, uas tsim cov hlau los ntawm kev xuas nrig ntaus, blanking, lossis stamping.Hlau stamping tuaj yeem suav nrog tsheb stamping, kev kho mob stamping, lossis lwm yam stamping, thiab tej zaum yuav xav tau ntau yam stampings nyob ntawm cov khoom.

♦ Feem ntau cov khoom stamped yuav tsum tau kho saum npoo.Feem ntau cov khoom stamped yuav tsum tau plating lossis sib txawv tom qab ua tiav los tiv thaiv ib puag ncig thiab ua kom lub neej ntev dua.

♦ Thaum lub sijhawm tsim khoom, QC lub tuam tsev yuav ua thawj zaug kev tshuaj xyuas / tshuaj xyuas / kev tshuaj xyuas zaum kawg ntawm cov khoom kom ntseeg tau tias cov khoom muaj kev ruaj ntseg zoo.