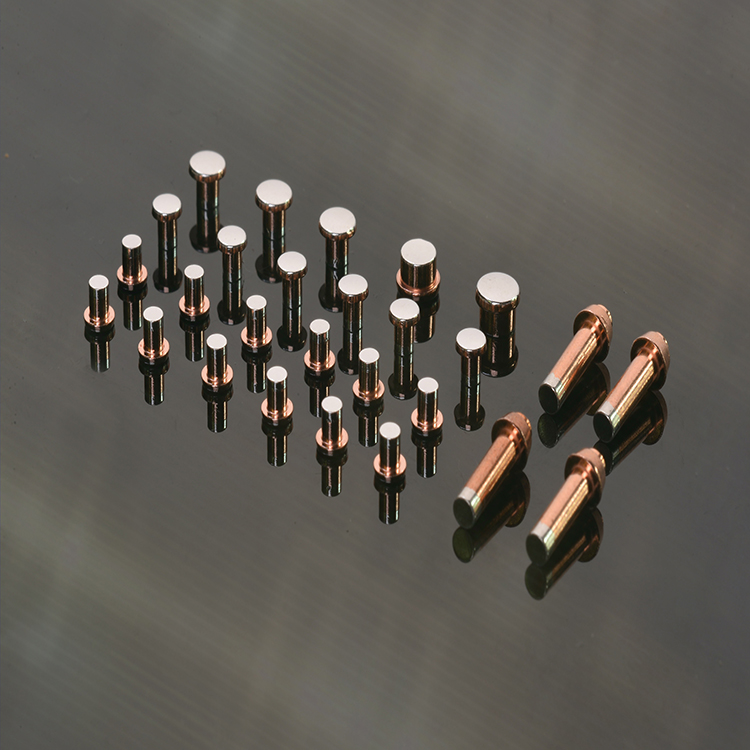

High Quality for Solid Rivet Manufacturers – Solid Contact rivet – ZHJ

China High Quality for Solid Rivet Manufacturers - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ Detail:

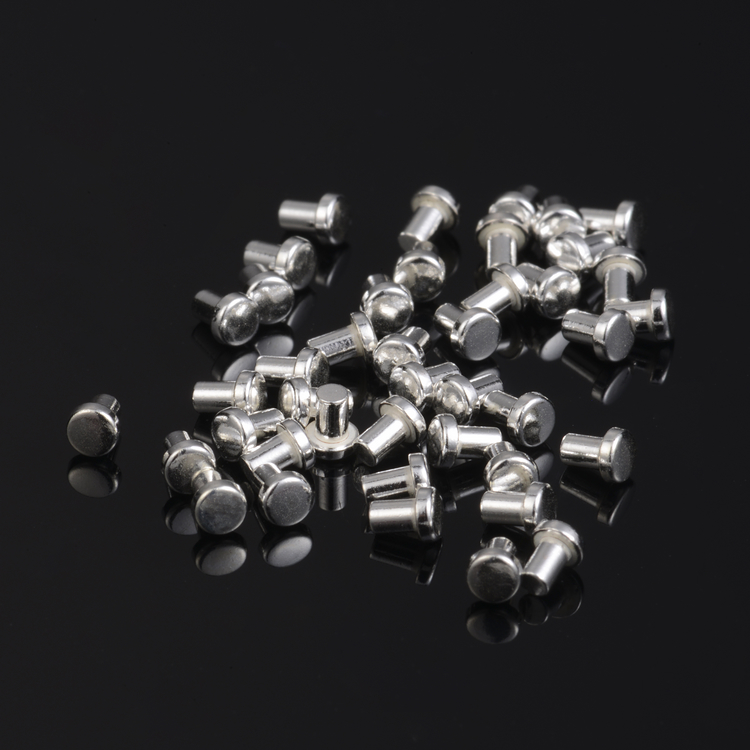

Solid rivets present a larger challenge when de-riveting. The manufactured head must be ground or milled off prior to pushing the rivet back through the hole. When removing solid rivets, the material of the component surrounding the hole must be considered. If the material is softer than the rivet, there is a chance it will be damaged. If the hardness is equal to or harder than the rivet the risk of damage is lower, as it will maintain its shape while the softer rivet is pushed back through. How the rivet was initially formed also plays a role in the de-riveting process. The larger the shank swell created in the forming process, the higher the risk of damage to the surrounding component.

Process flow

Rivet Making

Annealing

Finishing

Inspection

Drawing

Packing

Measure

|

Item |

Head diameter D(mm) |

Head thickness T(mm) |

Foot diameter d(mm) |

Foot length L(mm) |

Sphere radius R(mm) |

| Basic dimension |

1.2~12 |

0.15~3.00 |

0.75~6.00 |

0.45~8.56 |

1.2~40 |

| tolerance |

±0.05 |

-0.02∽ |

-0.02∽ |

±0.05 |

±2 |

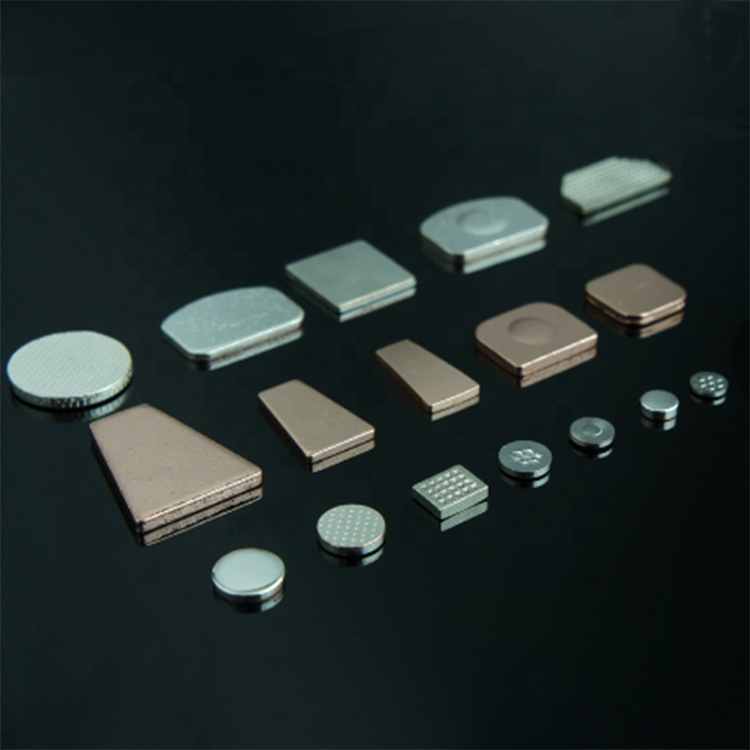

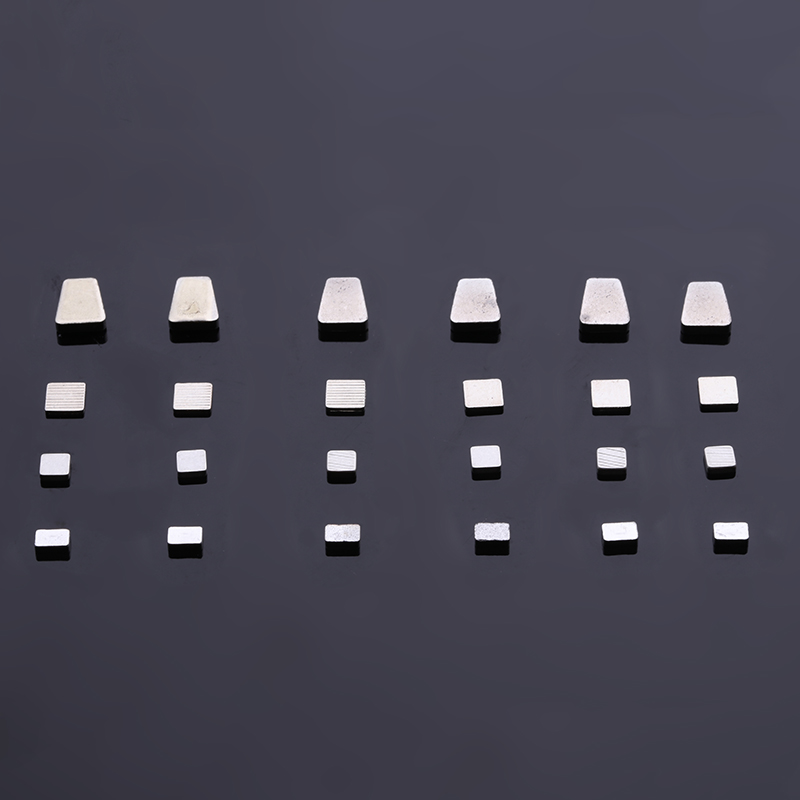

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for China High Quality for Solid Rivet Manufacturers - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ , The product will supply to all over the world, such as: Swaziland , Madagascar , Lithuania , Now we've been sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!