HOOLAHA METAL PAUDA

| Noi: |

| ʻO nā mea hoʻopili, nā mea hoʻokele kaapuni, nā thermostats, nā hoʻololi akamai, etc |

| Ka mea: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

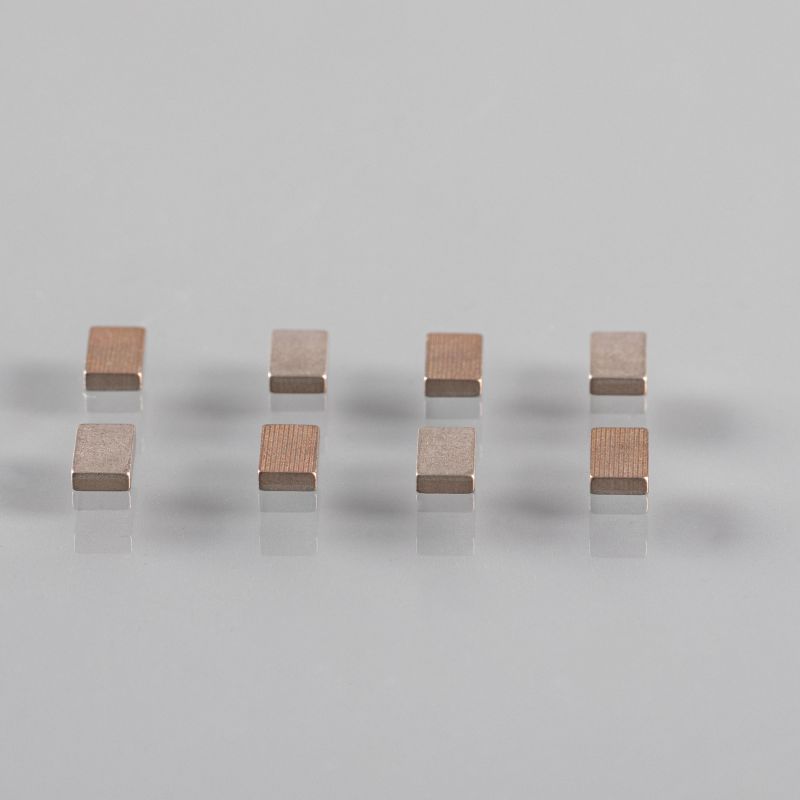

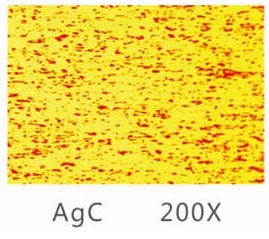

AgC

Microstructure

Ka wehewehe nui

Hōʻike nā mea hoʻopili AgC i ke kūpaʻa kiʻekiʻe loa i ka hoʻopili ʻana a me ke kūpaʻa haʻahaʻa.Piʻi ka kūʻē i ka welding me ka hoʻonui ʻana i ka maʻiʻo graphite.Loaʻa i nā mea AgC kahi ʻano lubrication ponoʻī ke hoʻohana ʻia e like me nā mea pili.

Ka Laihui

Hoʻohana nui ʻia i nā hoʻololi pale e like me MCB, MCCB, koena hoʻololi pale o kēia manawa, a i ʻole nā hoʻololi pale kaʻa.Hoʻohana maʻamau ka hoʻohana ʻana i ka asymmetric match me AgNi, AgW, AgWC a i ʻole Cu.

Na waiwai waiwai

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C maʻiʻo(wt.%) | 3±0.5 | 4±0.5 | 5±0.5 | 3±0.5 | 3.8±0.5 | 4±0.5 |

| Māmā (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Hiki i ka Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| HV paʻakikī | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Kaʻina hana hana | Sintering-Extruding | |||||

Nā ʻano huahana

AgW

Microstructure

Ka wehewehe nui

Hōʻike nā mea hoʻopili i hana ʻia me AgW i ke kūpaʻa anti-weld kiʻekiʻe a me ke kūpaʻa kiʻekiʻe i ka arc erosion ma muli o ka helu heheʻe kiʻekiʻe a me ka paʻakikī kiʻekiʻe o W, loaʻa iā lākou kahi conductivity uila a me ka wela.

Ka Laihui

Hoʻohana nui ʻia nā mea AgW i ka haʻahaʻa haʻahaʻa MCCB a me ACB a me nā hoʻololi pale.

Na waiwai waiwai

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Maʻiʻo Ag(wt.%) | 50±2 | 45±2 | 40±2 | 35±2 | 30±2 | 25±2 |

| Māmā (g/cm3) | ≥13.15 | ≥13.55 | ≥14.00 | ≥14.50 | ≥14.90 | ≥15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| HV paʻakikī | ≥100 | ≥110 | ≥120 | ≥130 | ≥145 | ≥160 |

| Kaʻina hana hana | Hoʻokomo | |||||

Nā ʻano huahana

AgWC

Microstructure

Ka wehewehe nui

ʻO nā mea hoʻopili AgWC i loaʻa i ka ʻāpana refractory WC he paʻakikī kiʻekiʻe a kūʻē i ka lole mīkini, kahi haʻahaʻa haʻahaʻa e pili ana i ka hoʻopili ʻana, a me ke kūpaʻa paʻa paʻa i ka lawelawe.Hoʻokumu ʻia nā pilina AgWC e ka infiltration metallurgy pauka.

Ka Laihui

Hoʻohana nui ʻia i nā mea hoʻololi koʻikoʻi, e like me nā breakers circuit.koena kaapuni o keia manawa.I nā manawa he nui, hoʻohana ʻia lākou i ka hoʻokūkū asymmetric me AgC

Na waiwai waiwai

| AgWC | AgWC | AgWC | AgWC | |

| Maʻiʻo Ag(wt.%) | 65±2 | 60±2 | 50±2 | 35±2 |

| Māmā (g/cm3) | ≥11.50 | ≥11.80 | ≥12.20 | ≥13.00 |

| ʻEleʻele (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| HV paʻakikī | ≥100 | ≥125 | ≥135 | ≥155 |

| Kaʻina hana hana | Hoʻokomo | |||

Nā ʻano huahana

AgWCC

Microstructure

Ka wehewehe nui

Ma muli o ke kiʻekiʻe Ag maʻiʻo , AgWCC pili i ka haʻahaʻa kū'ē kū'ē.Loaʻa iā lākou nā waiwai anti-weld kiʻekiʻe ma muli o ka loaʻa ʻana o ka tungsten carbide a me ka graphite me ka helu hoʻoheheʻe kiʻekiʻe.Hana ʻia nā pilina AgWCC e ka sintering.

Ka Laihui

Hoʻohana nui ʻia i nā mea hoʻololi koʻikoʻi, e like me nā breakers circuit.koena kaapuni o keia manawa.I nā manawa he nui, hoʻohana ʻia lākou i ka hoʻokūkū asymmetric me AgNi, AgW a i ʻole AgWC.

Na waiwai waiwai

| AgWCC | AgWCC | AgWCC | AgWCC | |

| Maʻiʻo Ag(wt.%) | 85±1 | 75±1 | 79±1 | 74.5±1 |

| Māmā (g/cm3) | ≥9.40 | ≥10.25 | ≥8.80 | ≥10.50 |

| Hiki i ka Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| HV paʻakikī | ≥50 | ≥80 | ≥60 | ≥75 |

| Kaʻina hana hana | Hui-hui-Sintering | |||

Nā ʻano huahana

AgNiC

Microstructure

Ka wehewehe nui

Hoʻohui nā hui AgNiC i nā pono o nā pilina AgNi a me AgC.Loaʻa iā lākou ke kū'ē maikaʻi i ka erosion uila a me nā waiwai anti-weld.

Ka Laihui

Hoʻohana nui ʻia nā pilina AgNiC ma MCCB, ACB.

Na waiwai waiwai

| AgNiC | AgNiC | 3AgNiC | |

| Maʻiʻo Ag(wt.%) | 67±1 | 73±1 | 94±1 |

| Māmā (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Hiki i ka Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| HV paʻakikī | ≥50 | ≥60 | ≥30 |

| Kaʻina hana hana | Hui-hui-Sintering | ||

Nā ʻano huahana

CuW

Microstructure

Ka wehewehe nui

Loaʻa i nā mea hoʻopili CuW ke kūpaʻa maikaʻi loa i ka arc erosion a me nā waiwai anti-weld a hiki i ka curret kiʻekiʻe loa.Hana ʻia nā pilina CuW i nā ʻano like ʻole ma o ka pauka metallurgy (kaomi / sintering a i ʻole infiltration).ʻO ka maʻi tungsten he 50% -80%.

Ka Laihui

Hoʻohana nui ʻia nā pilina CuW i nā mea hoʻololi uila kiʻekiʻe.Aia nā noi maʻamau i nā mea haʻihaʻi kaapuni uila kiʻekiʻe, nā hoʻololi hoʻouka, nā hoʻololi transformer nā mea hoʻololi tap a me nā mea hoʻopili arcing voltage haʻahaʻa.

Eia kekahi, hoʻohana nui ʻia nā mea CuW e like me nā electrodes, ma mua no ka welding.

Na waiwai waiwai

| CuW | CuW | CuW | |

| Cu maʻiʻo (wt.%) | 50±2 | 40±2 | 30±2 |

| Māmā (g/cm3) | ≥11.85 | ≥12.75 | ≥13.80 |

| EIec.Resistivity (p0 knm) | ≤3.20 | ≤3.70 | ≤4.10 |

| HV paʻakikī | ≥115 | ≥140 | ≥175 |

| Kaʻina hana hana | Hoʻokomo | ||

Nā ʻano huahana