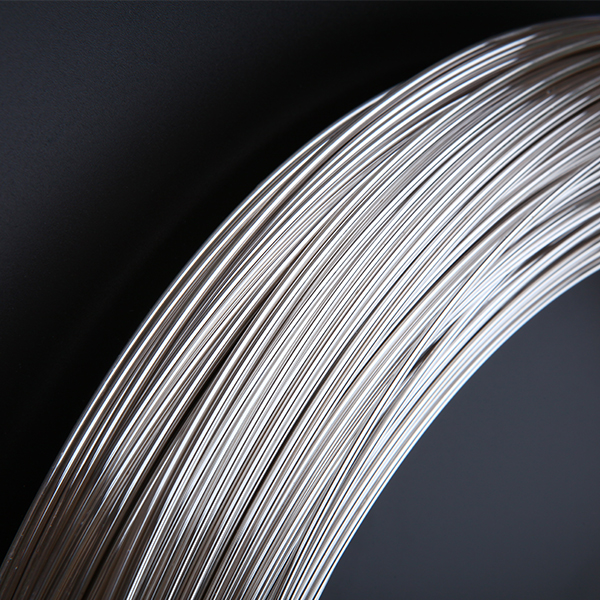

Wayoyin Alloy na Azurfa

| Aikace-aikace: |

| Masu tuntuɓar sadarwa, masu watsewar da'ira, ma'aunin zafi da sanyio, masu sauyawa masu hankali, da sauransu |

| Kayan: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. Karamin tsari

2. Bayanin Gabaɗaya

Azurfa da azurfar hatsi mai kyau (FAg) suna da babban ƙarfin lantarki da ƙarfin zafi, ƙarancin juriya da kwanciyar hankali, da kyakkyawan aiki.Don juriya na azurfa ga yashwar baka da walƙiya tuntuɓar suna iyakance, ƙarfin injin yana da ƙasa kaɗan, Saboda ƙaramin adadin nickel a cikin azurfa mai kyau, juriya ga lalatawar baka da ƙarfin injin ya fi na azurfa.

3. Iyakar aikace-aikace

An yi amfani da shi sosai a cikin ƙananan na'urori na yanzu, kamar relays, masu ƙidayar lokaci, maɓalli na taimako don kayan aikin gida, na'urorin sarrafawa, da sauransu.

4. Abubuwan Kaya

| Ag | FAg | |||

| Tips | Wayoyi | Tips | Wayoyi | |

| Ag abun ciki (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Yawan yawa (g/cm3) | ≥ 10.48 | ≥ 10.48 | ≥ 10.40 | ≥ 10.40 |

| Elec.Resistivity (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | 1.85 |

| Hardness HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Ƙarfin Tensile (MPa) |

| 230-380 |

| 250-380 |

| Tsawaitawa (%) |

| 2-30 |

| 2-30 |

| Tsarin sarrafawa | Extruding-Rolling | Extruding - Zane | Extruding-Rolling | Extruding - Zane |

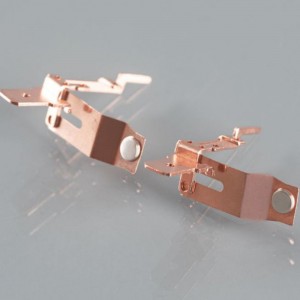

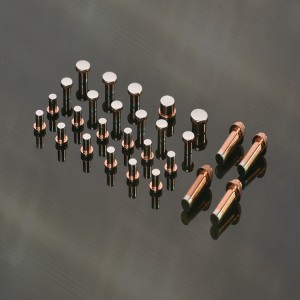

5. Nau'in Samfura

AgNi

1. Karamin tsari

2. Bayanin Gabaɗaya

Abubuwan AgNi suna da mafi girman juriya ga zaizayar baka da waldar lamba fiye da Ag ko FAg.Dukansu kaddarorin an inganta su tare da haɓaka abun ciki na Ni.Duk kayan AgNi suna nuna kyakkyawan aiki kuma suna da sauƙin walda don tuntuɓar masu tallafawa.Ƙananan hali zuwa canja wurin kayan aiki a aikace-aikacen DC.Abubuwan AgNi kayan kare muhalli ne.

3. Iyakar aikace-aikace

Abubuwan tuntuɓar AgNi suna samun kewayon aikace-aikace a cikin ƙananan na'urori masu sauya wutar lantarki.Ana amfani da su a cikin relays, ƙananan masu tuntuɓar juna, masu kunna haske, masu kula da zafin jiki da kuma a cikin masu sauyawa masu kariya (ana amfani da su a cikin nau'i-nau'i masu alaƙa, misali, a kan kayan AgC, AgZnO koAgSnO2).

4. Abubuwan Kaya

| Wayoyi | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ni Abun ciki (wt.%) | 10± 1 | 12± 1 | 15± 1 | 15± 1 | 20± 1 | 30± 1 |

| Yawan yawa (g/cm3) | ≥ 10.25 | ≥ 10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Hardness HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Ƙarfin Tensile (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Tsawaita(%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Tsarin sarrafawa | Sintering-Extruding | |||||

5. Nau'in Samfura

AgCdO

1. Karamin tsari

2. Bayanin Gabaɗaya

Lambobin AgCdO suna cikin rukunin waɗanda aka fi amfani da su a fagen ƙarancin wutar lantarki.Sun haɗu da juriya mai gamsarwa game da waldawar lamba tare da kyakkyawan juriya na zaizayar baka da ƙarancin juriya mai ƙarancin lamba akan cikakkiyar rayuwar sabis.An samar da su tare da fasaha daban-daban guda biyu, pre-oxidation-sintering-extruding da kuma ciki oxidation.A cikin duka biyun abun ciki na Cd0 na iya zuwa daga 10 zuwa 20wt. Duk da haka, Cd da Cd0 ana ɗauka su zama masu haɗari ga lafiya da muhalli.Don haka za a hana amfani da kayan AgCdO a cikin ƙasashe da yawa.

3. Iyakar aikace-aikace

Ana amfani da shi a kusan kowane nau'in na'urori masu sauyawa mara ƙarfi.Ana amfani da su yawanci a cikin microswitches, relays, masu sauya haske, masu tuntuɓar juna, masu sauya kayan aikin gida, wasu nau'ikan na'urori masu kariya, da kuma a wasu nau'ikan na'urorin da'ira.

4. Abubuwan Kaya

| Wayoyi | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| Abubuwan CdO (wt.%) | 10± 1 | 13.5 ± 1 | 15± 1 | 10± 1 | 12± 1 | 15± 1 | 17±1 |

| Yawan yawa (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Hardness HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Ƙarfin Tensile (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Tsawaita(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Tsarin sarrafawa | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||||

5. Nau'in Samfura

AgZnO

1. Karamin tsari

2. Bayanin Gabaɗaya

Babban juriya da waldawar lamba yana kwatanta kayan AgZnO.Hakanan suna nuna juriya mai kyau akan yashwar baka.Juriyar tuntuɓar AgZnO yana ƙoƙarin zama sama da na AgCd0.Ana iya samar da AgZnO ta hanyar pre-oxidation-sintering-extruding, hada-hadar daɗaɗɗen-hanyoyi da kuma ta hanyar iskar oxygenation na ciki.Abubuwan AgZnO sune muhalli - kayan kariya.

3. Iyakar aikace-aikace

An fi amfani dashi a cikin na'urori masu rarrabawa, musamman a cikin na'urori na duniya.Sauran filayen aikace-aikacen sune na'urorin kariya na mota, saura na'urorin da'ira da kuma relays AC.

4. Abubuwan Kaya

| Wayoyi | AgZnO | AgZnO |

| Abun ciki na ZnO(wt.%) | 8±1 | 10± 1 |

| Yawan yawa (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Hardness HV | E30 | 85 |

| Ƙarfin Tensile (MPa) | 285-350 | 285-350 |

| Tsawaita(%) | 15-25 | 12-20 |

| Tsarin sarrafawa | Pre-oxidation - Sintering-Extruding | |

5. Nau'in Samfura

Farashin AgSnO2

1. Karamin tsari

2. Bayanin Gabaɗaya

AgSnO2/AgSn021n203 kayan tuntuɓar lantarki ne masu dacewa da muhalli.Suna da kyawawan wasan kwaikwayo a cikin abubuwan hana lalata da kuma kayan walda, kuma suna da kyawawan kayan canja wurin kayan abu a cikin kewayawa na DC.Babban masana'antu matakai ne na ciki hadawan abu da iskar shaka tsari, pre-oxidation tsari, foda metallurgy tsari, sinadaran shafi tsari, da dai sauransu.

3. Iyakar aikace-aikace

Yadu amfani a daban-daban irin contactors , relays, kewaye breakers da switches, da dai sauransu.

4. Abubuwan Kaya

Farashin AgSnO2

| Wayoyi | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | AgSn02 |

| Abubuwan da ke cikin SnO2 (wt.%) | 10± 1 | 10± 1 | 12± 1 | 12± 1 | 15± 1 |

| Yawan yawa (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistivity (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Ƙarfin Tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Tsawaita(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Tsarin sarrafawa | Pre-oxidation-Sintering-Extruding | Rufin Sinadarai | Hadawa-Sintering-Extruding | ||

AgSnO2In203

| Wayoyi | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 |

| Ag abun ciki (wt.%) | 90± 1 | 88±1 | 92±1 | 88±1 | 85.5 ± 1 |

| Yawan yawa (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Juriya (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Hardness HV | ≥ 100 | ≥ 100 | ≥90 | ≥95 | ≥95 |

| Ƙarfin Tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Tsawaita(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Tsarin sarrafawa | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||

5. Nau'in Samfura

Bayanin AgSnO2In2O3

1. Bayanin Gabaɗaya

2. Karamin tsari

AgSnO2lAgSn021n203 kayan tuntuɓar lantarki ne masu dacewa da muhalli.Suna da kyawawan wasan kwaikwayo a cikin abubuwan hana lalata da kuma kayan walda, kuma suna da kyawawan kayan canja wurin kayan abu a cikin kewayawa na DC.Babban masana'antu matakai ne na ciki hadawan abu da iskar shaka tsari, pre-oxidation tsari, foda metallurgy tsari, sinadaran shafi tsari, da dai sauransu.

3. Iyakar aikace-aikace

Yadu amfani a daban-daban irin contactors , relays, kewaye breakers da switches, da dai sauransu.

4. Abubuwan Kaya

Farashin AgSnO2

| Wayoyi | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | AgSn02 |

| Abubuwan da ke cikin SnO2 (wt.%) | 10 ± 1 | 10 ± 1 | 12± 1 | 12± 1 | 15 ± 1 |

| Yawan yawa (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Resistivity (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Hardness HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Ƙarfin Tensile (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Tsawaita(%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Tsarin sarrafawa | Pre-oxidation-Sintering-Extruding | Rufin Sinadarai | Hadawa-Sintering-Extruding | ||

AgSnO2In203

| Wayoyi | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 | Farashin AgSnO2 |

| Ag abun ciki (wt.%) | 90± 1 | 88±1 | 92±1 | 88±1 | 85.5 ± 1 |

| Yawan yawa (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Resistivity (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Hardness HV | ≥ 100 | ≥ 100 | ≥90 | ≥95 | ≥95 |

| Ƙarfin Tensile (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Tsawaita(%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Tsarin sarrafawa | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||