LAMBAR KARFE FOLU

| Aikace-aikace: |

| Masu tuntuɓar sadarwa, masu watsewar da'ira, ma'aunin zafi da sanyio, masu sauyawa masu hankali, da sauransu |

| Kayan: |

| AgC,AgW,AgWC,AgWCC,AgNiC,CuW |

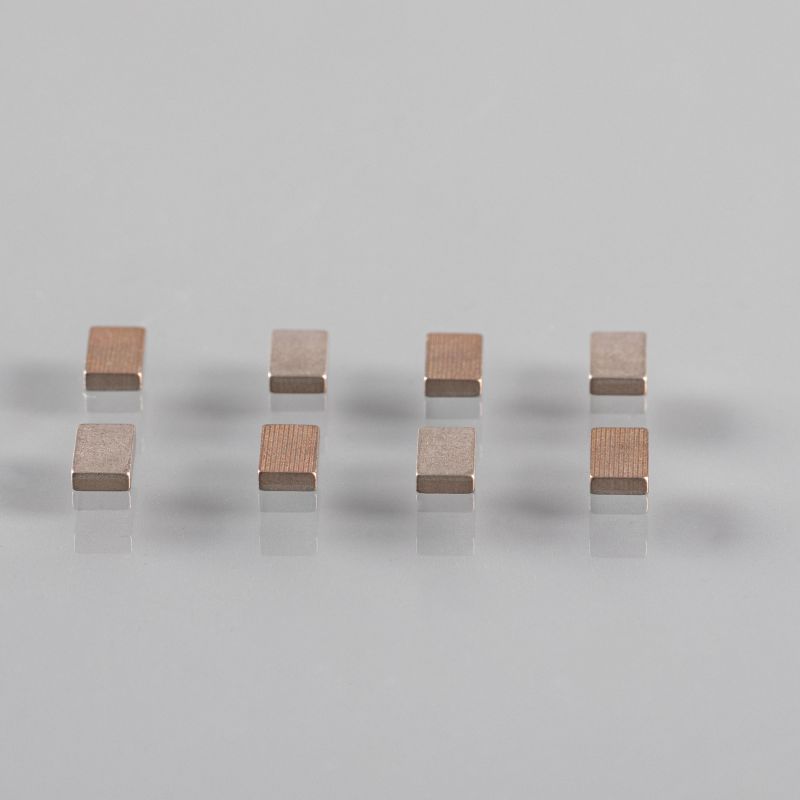

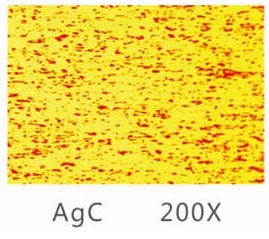

AgC

Karamin tsari

Babban Bayani

Abubuwan tuntuɓar AgC suna nuna juriya sosai akan waldawar lamba da ƙarancin juriya.Juriya da walda yana ƙaruwa tare da haɓaka abun ciki na graphite.Abubuwan AgC suna da halayen sa mai-kai lokacin amfani da su azaman lambobi masu zamewa.

Iyakar aikace-aikace

Ana amfani da shi a cikin musanya masu kariya kamar MCBs, MCCBs, saura na'urorin kariya na yanzu, ko na'urorin kariya na mota.Aikace-aikacen yawanci yana cikin daidaitawar asymmetric tare da AgNi, AgW, AgWC ko Cu.

Kayayyakin Kayayyaki

| AgC | AgC | AgC | AgC | AgC | AgC | |

| C abun ciki(wt.%) | 3 ± 0.5 | 4 ± 0.5 | 5 ± 0.5 | 3 ± 0.5 | 3.8 ± 0.5 | 4 ± 0.5 |

| Yawan yawa (g/cnre) | ≥9.10 | ≥8.9 | ≥8.60 | ≥9.10 | ≥9.00 | ≥8.9 |

| Elec.Resistivity (.10•cm) | ≤2.10 | ≤2.20 | ≤2.30 | ≤2.10 | ≤2.20 | ≤2.20 |

| Hardness HV | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 | ≥42 |

| Tsarin sarrafawa | Sintering-Extruding | |||||

Nau'in Samfura

AgW

Karamin tsari

Babban Bayani

Lambobin da aka yi da AgW suna nuna babban juriya na walda da kuma juriya ga zaizayar baka saboda babban narkewar wuri da taurin W, kuma suna da kyakkyawar wutar lantarki da wutar lantarki.

Iyakar aikace-aikace

An fi amfani da kayan AgW a cikin ƙananan ƙarfin lantarki MCCB da ACB da masu sauyawa masu kariya.

Kayayyakin Kayayyaki

| AgW | AgW | AgW | AgW | AgW | AgW | |

| Ag abun ciki(wt.%) | 50± 2 | 45±2 | 40± 2 | 35± 2 | 30± 2 | 25± 2 |

| Yawan yawa (g/cm3) | 13.15 | ≥13.55 | ≥14.00 | ≥ 14.50 | ≥ 14.90 | ≥ 15.40 |

| EIec.Resistivity (1.10•cm) | ≤3.00 | ≤3.20 | ≤3.40 | ≤3.60 | ≤3.80 | ≤4.20 |

| Hardness HV | ≥ 100 | ≥110 | ≥120 | ≥ 130 | ≥145 | ≥160 |

| Tsarin sarrafawa | Shiga ciki | |||||

Nau'in Samfura

AgWC

Karamin tsari

Babban Bayani

Abubuwan tuntuɓar AgWC waɗanda ke ɗauke da ɓangaren refractory WC suna da ƙaƙƙarfan tauri da juriya ga lalacewa na inji, ƙarancin ɗabi'a zuwa walda, da ingantacciyar juriyar lamba a cikin sabis.Ana samar da lambobin sadarwa na AgWC ta hanyar shigar da ƙarfe na foda.

Iyakar aikace-aikace

An fi amfani da shi a cikin na'urori masu ɗaukar nauyi, kamar na'urori masu rarrabawa.saura na yanzu kewaye breakers.A yawancin lokuta ana amfani da su a wasan asymmetric tare da AgC

Kayayyakin Kayayyaki

| AgWC | AgWC | AgWC | AgWC | |

| Ag abun ciki(wt.%) | 65± 2 | 60± 2 | 50± 2 | 35± 2 |

| Yawan yawa (g/cm3) | ≥ 11.50 | ≥ 11.80 | ≥12.20 | ≥13.00 |

| Elec.Resistivity (1.10•cm) | ≤3.30 | .A.50 | 4.50 | 5.20 |

| Hardness HV | ≥ 100 | ≥125 | ≥135 | ≥155 |

| Tsarin sarrafawa | Shiga ciki | |||

Nau'in Samfura

Farashin AgWCC

Karamin tsari

Babban Bayani

Saboda babban abun ciki na AgWCC, lambobin sadarwa na AgWCC suna da ƙarancin juriya na lamba.Suna da kyawawan kaddarorin anti-welding saboda sun ƙunshi tungsten carbide da graphite tare da babban narkewa.Ana kera lambobin AgWCC ta hanyar sintiri.

Iyakar aikace-aikace

An fi amfani da shi a cikin na'urori masu ɗaukar nauyi, kamar na'urori masu rarrabawa.saura na yanzu kewaye breakers.A yawancin lokuta ana amfani da su a wasan asymmetric tare da AgNi, AgW ko AgWC.

Kayayyakin Kayayyaki

| Farashin AgWCC | Farashin AgWCC | Farashin AgWCC | Farashin AgWCC | |

| Ag abun ciki(wt.%) | 85±1 | 75±1 | 79±1 | 74.5 ± 1 |

| Yawan yawa (g/cm3) | ≥9.40 | ≥ 10.25 | ≥8.80 | ≥ 10.50 |

| Elec.Resistivity (u0•cnn) | ≤3.40 | ≤3.40 | ≤3.80 | ≤3.45 |

| Hardness HV | ≥50 | ≥80 | ≥60 | ≥75 |

| Tsarin sarrafawa | Mixing-Compacting-Sintering | |||

Nau'in Samfura

AgNiC

Karamin tsari

Babban Bayani

Lambobin AgNiC sun haɗu da fa'idodin lambobin AgNi da AgC.Suna da kyakkyawan juriya ga yashwar lantarki da kaddarorin walda.

Iyakar aikace-aikace

Ana amfani da lambobin sadarwa na AgNiC a cikin MCCB, ACB.

Kayayyakin Kayayyaki

| AgNiC | AgNiC | 3 AgNiC | |

| Ag abun ciki(wt.%) | 67±1 | 73±1 | 94±1 |

| Yawan yawa (g/cm3) | ≥8.70 | ≥9.10 | ≥8.50 |

| Elec.Resistivity (.10•cm) | ≤4.50 | ≤3.50 | ≤3.50 |

| Hardness HV | ≥50 | ≥60 | ≥30 |

| Tsarin sarrafawa | Mixing-Compacting-Sintering | ||

Nau'in Samfura

KuW

Karamin tsari

Babban Bayani

Kayan tuntuɓar CuW suna da kyakkyawan juriya ga yashwar baka da kaddarorin walda har zuwa babban curret.Ana samar da lambobin CuW a cikin nau'ikan sifofi iri-iri ta hanyar ƙarfe na foda (latsawa / sintering ko kutse).Tungsten abun ciki shine 50% -80%.

Iyakar aikace-aikace

Ana amfani da lambobin CuW galibi a cikin matsakaita da babban ƙarfin wutar lantarki.Aikace-aikace na yau da kullun suna cikin masu fasa wutar lantarki mai ƙarfi, masu ɗaukar nauyi, masu canza canjin wuta da ƙananan lambobin wutar lantarki.

Bugu da kari, kayan CuW ana amfani da su sosai azaman lantarki, da farko don walda.

Kayayyakin Kayayyaki

| KuW | KuW | KuW | |

| Cu Abun ciki (wt.%) | 50± 2 | 40± 2 | 30± 2 |

| Yawan yawa (g/cm3) | ≥11.85 | ≥12.75 | ≥ 13.80 |

| EIec.Resistivity (p0 cm) | ≤3.20 | ≤3.70 | ≤4.10 |

| Hardness HV | ≥115 | ≥ 140 | ≥175 |

| Tsarin sarrafawa | Shiga ciki | ||

Nau'in Samfura