Good Quality Hollow Rivets – Solid Contact rivet – ZHJ

China Good Quality Hollow Rivets - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ Detail:

Solid rivets present a larger challenge when de-riveting. The manufactured head must be ground or milled off prior to pushing the rivet back through the hole. When removing solid rivets, the material of the component surrounding the hole must be considered. If the material is softer than the rivet, there is a chance it will be damaged. If the hardness is equal to or harder than the rivet the risk of damage is lower, as it will maintain its shape while the softer rivet is pushed back through. How the rivet was initially formed also plays a role in the de-riveting process. The larger the shank swell created in the forming process, the higher the risk of damage to the surrounding component.

Process flow

Rivet Making

Annealing

Finishing

Inspection

Drawing

Packing

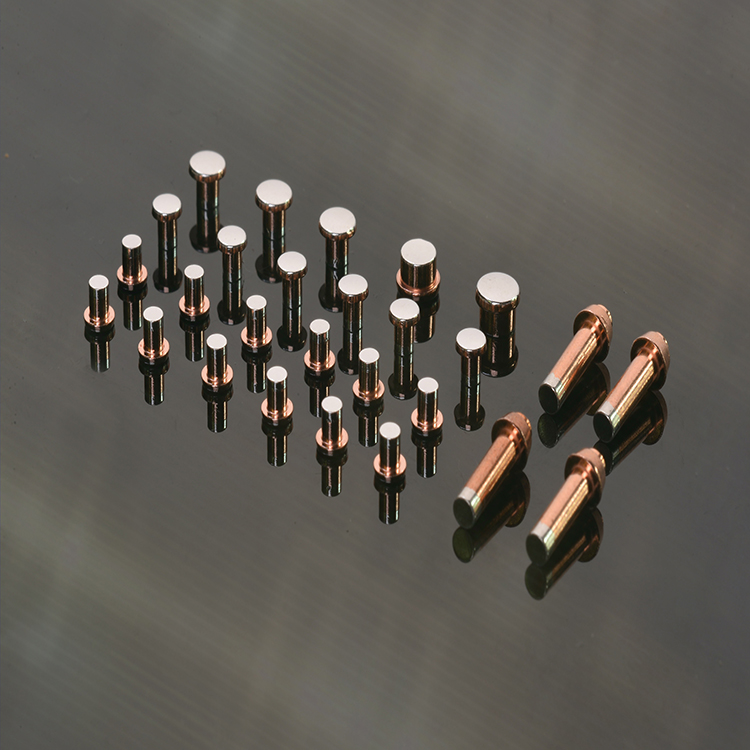

Measure

|

Item |

Head diameter D(mm) |

Head thickness T(mm) |

Foot diameter d(mm) |

Foot length L(mm) |

Sphere radius R(mm) |

| Basic dimension |

1.2~12 |

0.15~3.00 |

0.75~6.00 |

0.45~8.56 |

1.2~40 |

| tolerance |

±0.05 |

-0.02∽ |

-0.02∽ |

±0.05 |

±2 |

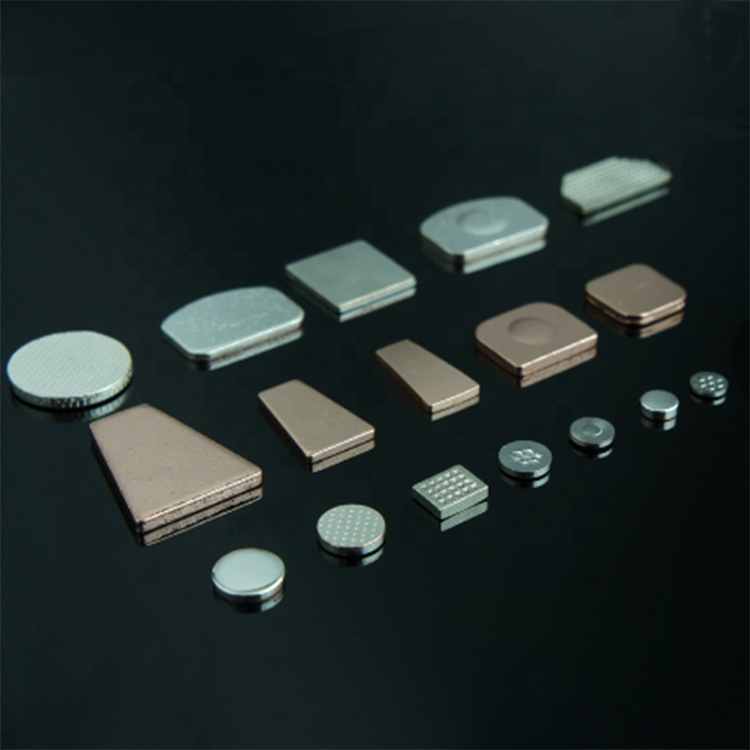

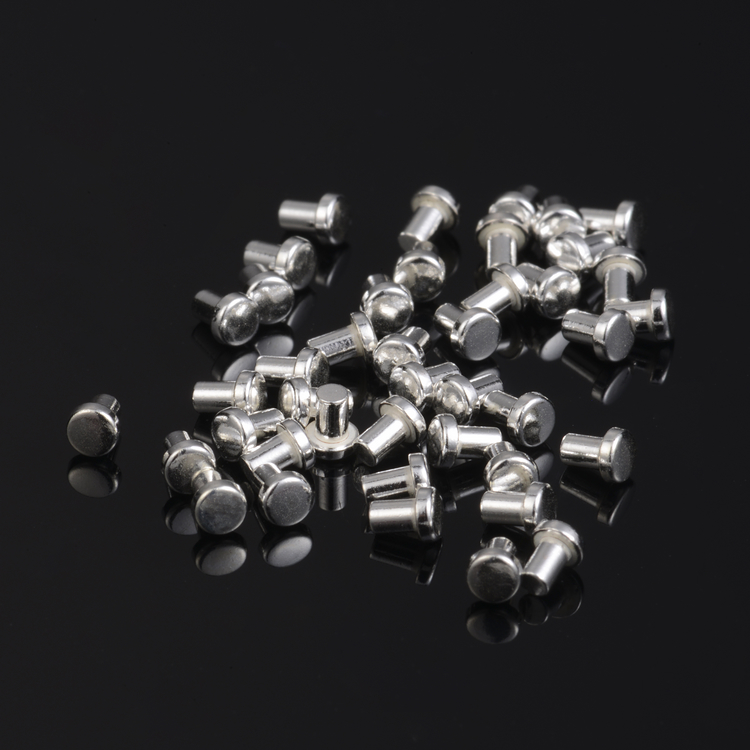

Product detail pictures:

Related Product Guide:

With our outstanding administration, powerful technical capability and strict top quality handle procedure, we go on to provide our purchasers with reliable good quality, reasonable selling prices and excellent services. We goal at becoming certainly one of your most responsible partners and earning your gratification for China Good Quality Hollow Rivets - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ , The product will supply to all over the world, such as: French , Sao Paulo , Cairo , With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.