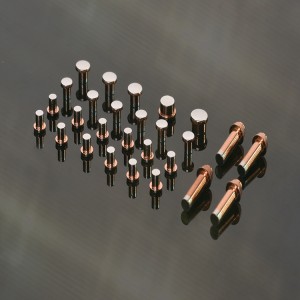

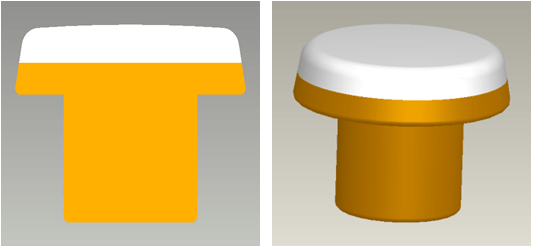

Bimetal Contact Rivet

Product Features

1.Double composite riveting efficiently save precious metals and reduce the cost

2.mprove the contact rivet riveting performance.

3.Apply continuous automation production.

Main Application

Automobile electric appliances,household appliances,replays,contactor,

Thermostat,all kinds of switch,aviation appliances,timer and electronic appliances.

Process flow

Rivet Making

Annealing

Finishing

Inspection

Drawing

Packing

Product Description: They have good performances in anti-erosion and anti-welding properties, and have good anti-material transfer property in DC switching circuit. The main manufacturing processes are internal oxidation process, pre-oxidation process, powder metallurgy process, chemical coating process, etc. Silver Tin Oxide Bimetal Contact Rivets have lower cost than solid rivets.

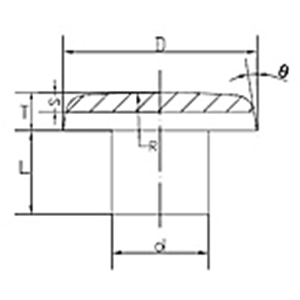

Measure:

| Item | Head diameter D(mm) | Head thickness T(mm) | layer diameter S(mm) | Shank diameter D(mm) | Shank length L(mm) | Sphere radium SR(mm) | Mold ratio8(▫) |

|

specifl-cation |

2.5 |

0.6,0.8,1.0 |

0.3~0.4 |

1.2,1.5 |

1~2 |

4,6 |

9 |

|

3.0 |

0.8,1.0,1.2 |

0.35~0.50 |

1.50 |

6,8 |

|||

|

3.5 |

1.50,2.0 |

1~3 |

|||||

|

4.0 |

1.0,1.2,1.5 |

2.0 |

8,10 |

||||

|

4.5 |

2.0,2.5 |

||||||

|

5.0 |

1.0,1.2,1.5,2.0 |

0.40~0.60 |

2.5 |

10,15 |

|||

|

5.5 |

2.5,3.0 |

||||||

|

6.0 |

3.0 |

15,20 |

|||||

|

6.5 |

1.2,1.5,2.0 |

0.50~0.70 |

3.0,3.5 |

||||

|

7.0 |

3.5 |

20,25 |

|||||

|

8.0 |

4.0 |

||||||

| head and shank coaxiality | ±0.1 | ±0.05 | S≤0.4+0.6 S>0.4-0.06 | -0.02,-0.1 | ,+0.15 | ±0.2R | ±2 |